Display screen structure

A technology of display screen and transparent display screen, which is applied in optics, instruments, nonlinear optics, etc., and can solve the problems of reduced display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

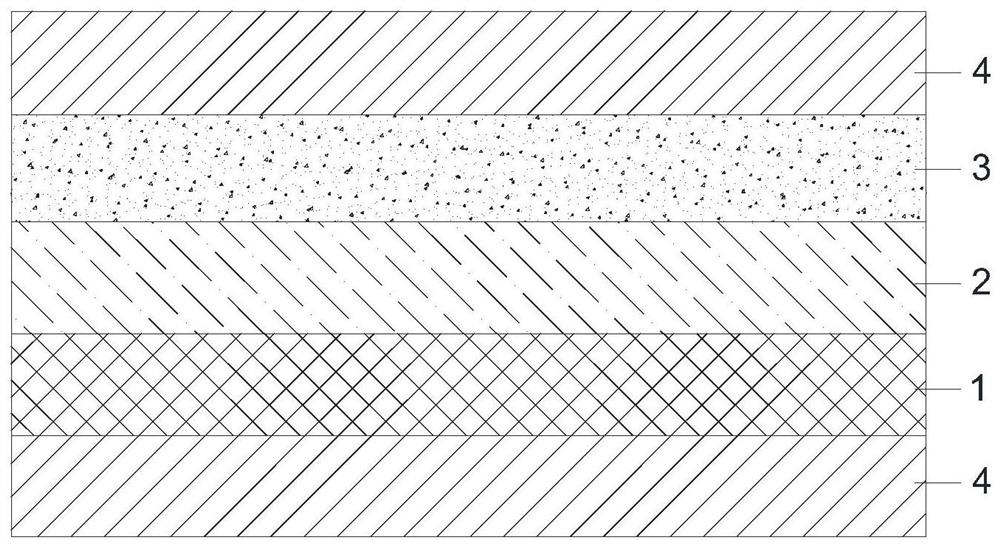

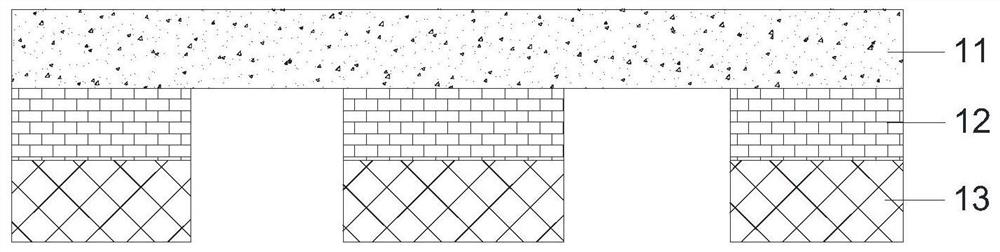

[0028] like figure 1 and image 3 As shown, the above-mentioned transparent display screen 1 may include a transparent base layer 11, a circuit layer 12 and an LED lamp group 13, wherein the circuit layer 12 is arranged on the front side of the transparent base layer 11, and the LED lamp group 13 is arranged on the front side of the circuit layer 12 side, and the LED lamp group 13 is electrically connected to the circuit layer 12 . In addition, the above-mentioned polymer dispersed liquid crystal display layer 2 is disposed on the reverse side of the transparent base layer 11 , and at the same time, the front side of the LED lamp group 13 is covered with the first protective layer 4 . In this embodiment, the circuit layer 12 can be a metal grid circuit layer, a nano-silver wire circuit layer, an indium tin oxide (Indium tin oxide, ITO) circuit layer, or a flexible copper clad laminate (Flexible Copper Clad Laminate, FCCL) circuit layer. of any kind. For example, the transpa...

Embodiment 2

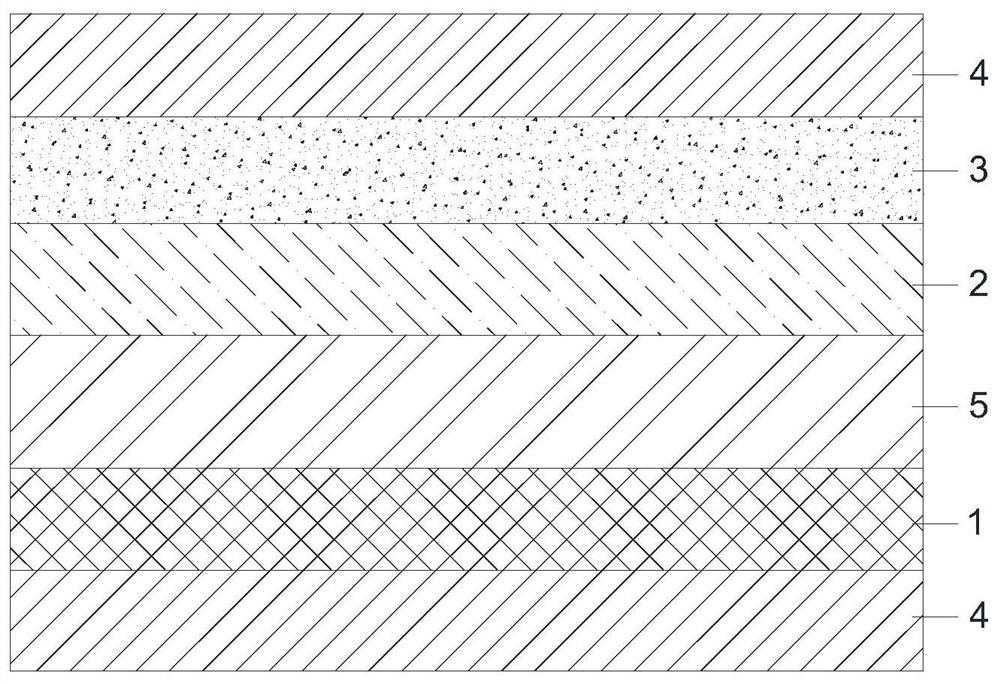

[0030] like figure 2 As shown, a layer of first protective layer 4 is provided on the reverse side of the above-mentioned transparent explosion-proof layer 3, and a layer of first protective layer 4 is also provided on the front side of the transparent display screen 1. At the same time, the above-mentioned transparent display screen 1 and the above-mentioned polymer A second protective layer 5 is arranged between the dispersed liquid crystal display layers 2 . In this embodiment, the first protective layer 4 and the second protective layer 5 are the same, and both may be any one of a transparent glass layer, a transparent adhesive layer, a transparent ink layer, and a transparent film layer. In this embodiment, the purpose of setting the first protective layer 4 on the opposite side of the transparent explosion-proof layer 3 is mainly to increase the flexibility and hardness of the product and protect the product from damage. In application scenarios requiring high flexibil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com