Release mechanism for a torque tool

A trigger mechanism and tool technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of cost-intensive, complex structure, manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

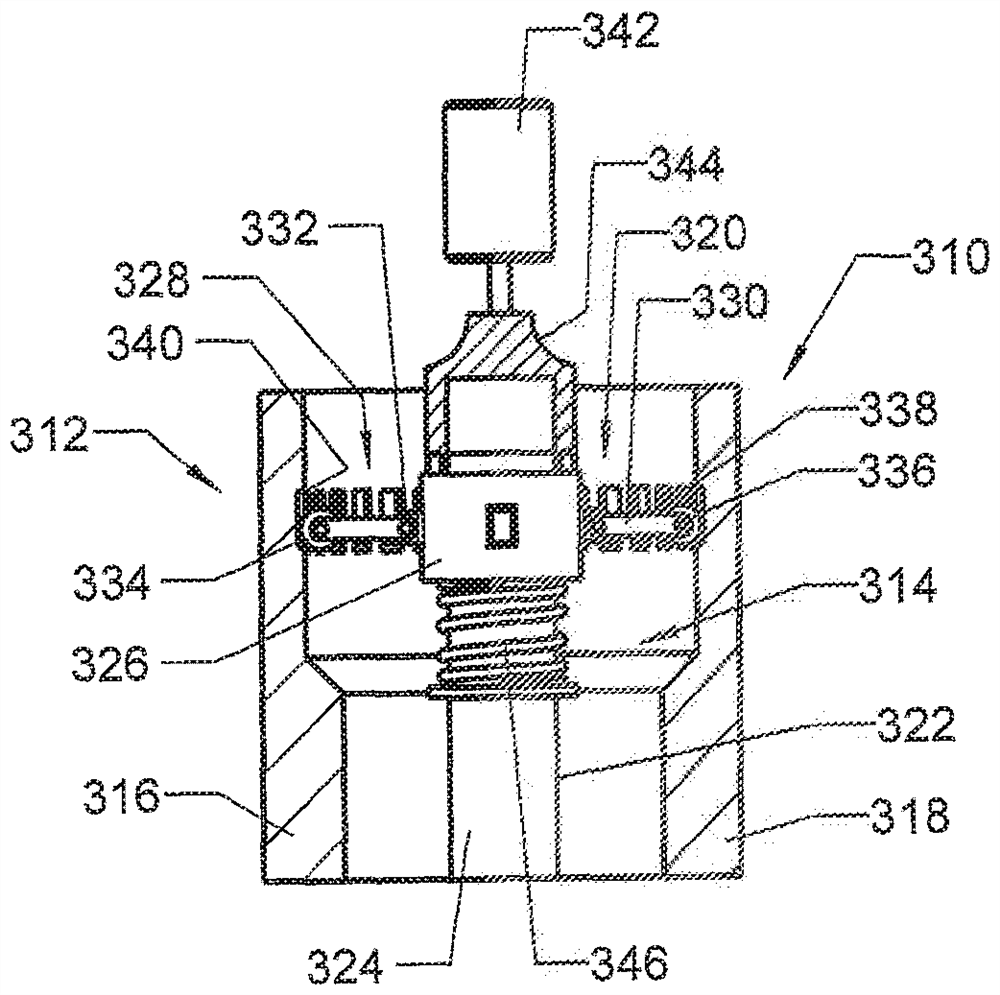

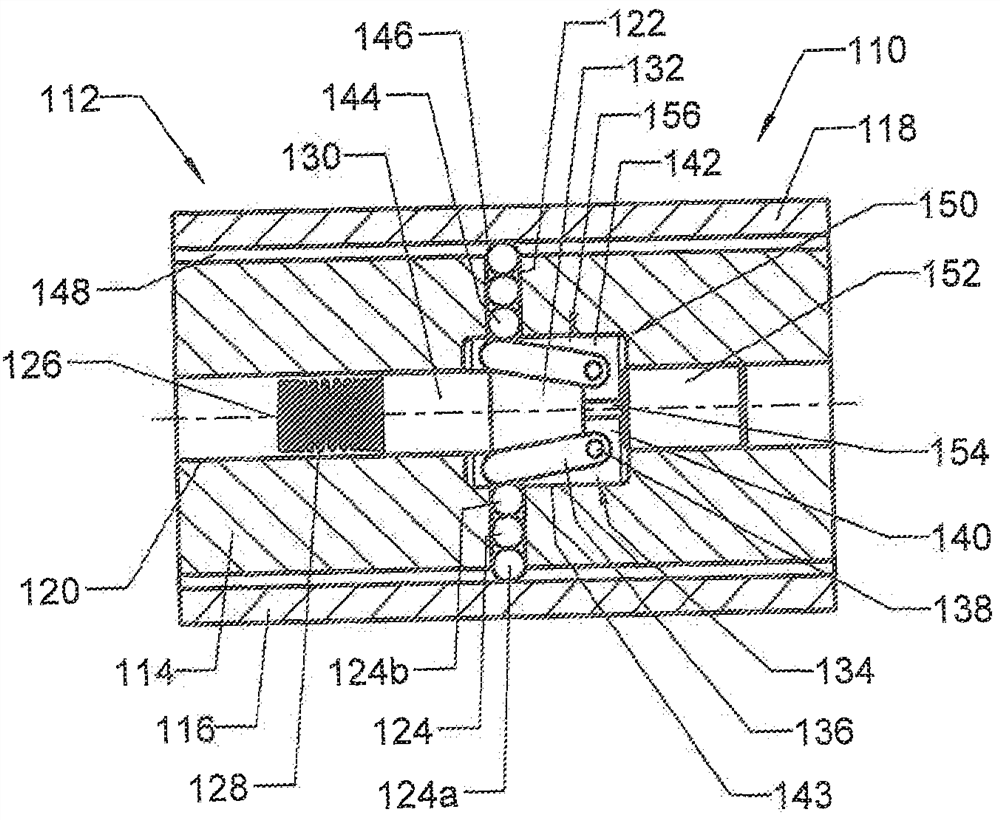

[0042] exist figure 1 10 denotes a triggering mechanism according to the invention of a torque tool 12 for tightening threaded fasteners or the like with a target torque. Torque Tool 12 in figure 1 The center is shown in section as an axial longitudinal section. The torque tool 12 comprises a cylindrical base body 14 with a housing-shaped drive body 16 . A drive handle 20 is fastened in the region 18 of the drive body 16 . The driving handle 20 is firmly connected with the driving body. The drive handle 20 can be configured, for example, as a torsion bar, at which strain gauges are arranged for sensing the torque to be transmitted.

[0043] A lifting magnet 24 as an electric actuator is arranged in the cavity 22 of the drive body 16 . The lifting magnet 24 has a screw 26 . When the lifting magnet 24 is actuated, the screw 26 acts on a lever arrangement 28 of a locking mechanism 30 which is arranged between the base body 14 and the drive body 16 . The locking mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com