Fryer

A fryer and pot body technology, applied in the field of fryer, can solve the problems of unstable edible oil quality, low heating efficiency, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

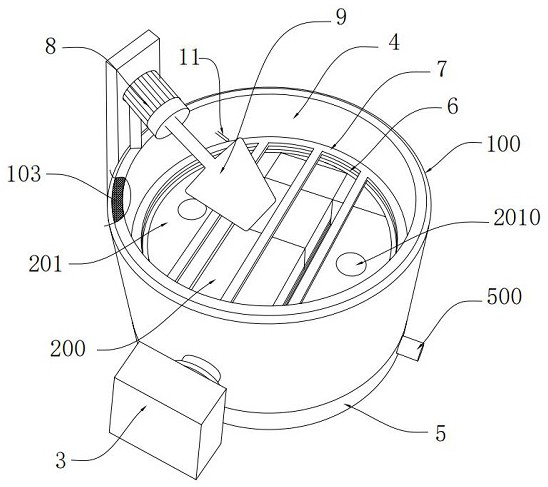

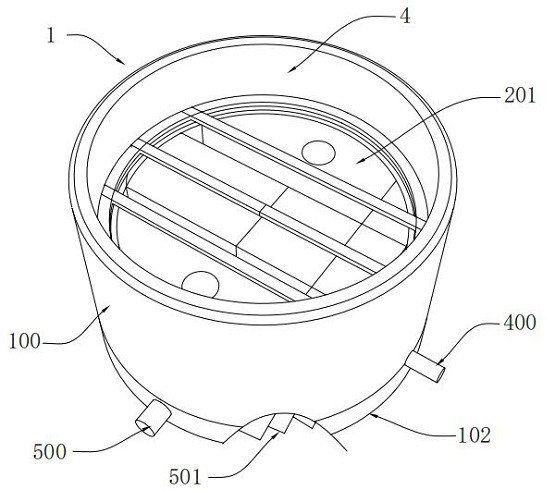

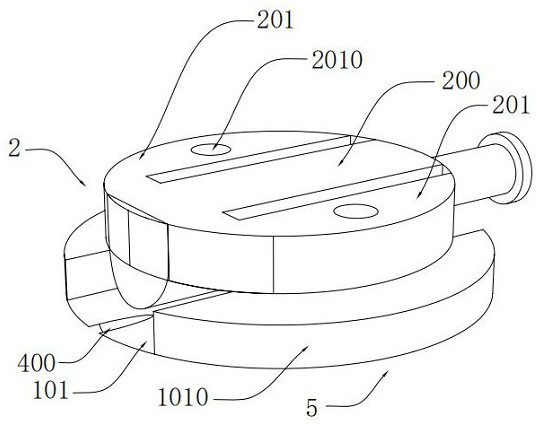

[0033] Such as Figure 1-8As shown, this embodiment provides a fryer, which includes a pot body 1, a heating liner 2 and a burner 3; wherein, the pot body 1 includes a pot wall 100, a partition 101 and a bottom plate 102; The pot wall 100 is a double-layer structure, and the interlayer is filled with an insulating layer 103; the bottom plate 102 is arranged on the lower end surface of the pot wall 100, the partition 101 is arranged in the inner cavity of the pot body 1, and the The inner cavity of the pot body 1 is divided into an upper frying chamber 4 and a lower heating chamber 5. The partition 101 is arranged obliquely. The exhaust pipe 500 is set; the slag discharge pipe 400 is set at the lowest position where the partition 101 is connected with the pot wall 100; the heating liner 2 is set in the frying chamber 4 and erected on the The partition plate 101, the inner cavity pipeline of the heating liner 2 communicates with the heating chamber 5; the burner 3 is arranged o...

Embodiment 2

[0040] In this embodiment, the partition plate 101 adopts a planar plate structure, which is not shown in the figure, and the rest of the structure is the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] Such as Figure 9 As shown, the pot wall is a double-layer structure and an insulating layer is filled in the interlayer, and an oil overflow collection tank 12 is set in the upper end surface of the pot wall of the double-layer structure; an oil overflow collection pipe 13 is also included, and the oil overflow The collecting pipe 13 communicates with the outside of the overflow oil collection tank 12 and the pot wall 100; preferably in the present embodiment, a stepped groove is provided at the junction of the inner side wall of the pot wall 100 and the upper end surface as the oil overflow collection tank 12, and the pot wall The outer wall of the pot wall 100 constitutes the tank wall of the oil overflow collection tank 12, and the frying chamber 4 is directly connected with the oil overflow collection tank 12. When a large amount of foam generated by frying overflows the upper end surface of the inner wall of the pot wall 100, it will enter the stepped tank , and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com