Water-saving drying and washing integrated shoe washing machine and method

A technology for a shoe washing machine and a cover, applied in the field of shoe washing machines, can solve the problems of waste of resources, complicated structure, secondary pollution of shoes, etc., and achieve a comprehensive effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] The technical problem to be solved by the present invention is to solve the problems that the traditional rotary shoe washing machine has cleaning dead angles, poor cleaning ability inside the shoes, large mechanical volume, large washing water consumption and easy damage to the shoe body after long-term soaking, etc., and provides a A new shoe washing device realized by using the principle of vibration.

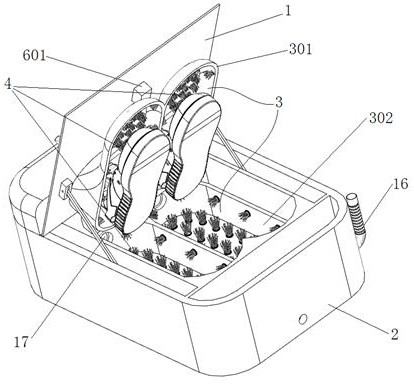

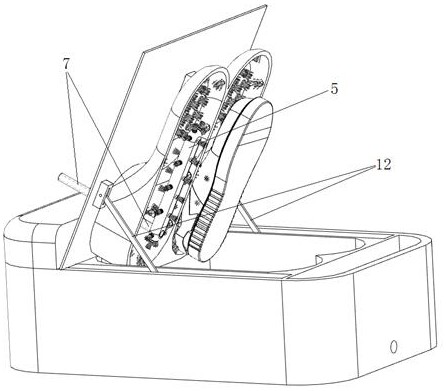

[0038] refer to figure 1 , figure 2 The shoe washing machine provided by the present invention includes a machine cover 1 and a box body 2. When the machine cover 1 and the box body 2 are tightly closed, the inside of the machine cover 1 and the box body 2 forms a cleaning cabin 3 with the outer contour of shoes. The inner surface of the cleaning cabin 3 is provided with a shoe outer brush 4 . In the cleaning cabin 3, a shoe inner brush 5 is suspended, and the shoe inner brush 5 is connected with the output end of the transmission device 6. The shoe inner brush 5 h...

no. 2 example

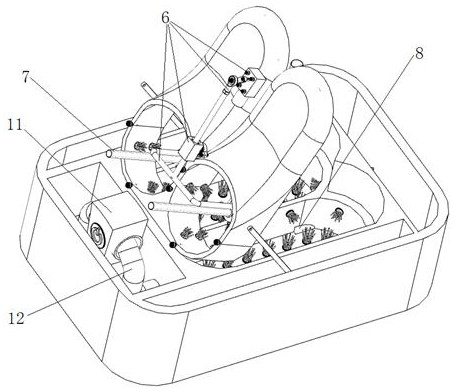

[0044] refer to image 3 , Figure 8 , Figure 9, on the basis of the foregoing examples, in order to further optimize the scheme of the present invention and realize the integration of washing and drying, a dryer 11 is further added in this example. The purpose of adding dryer 11 is to dry the wet shoes after cleaning. Airway circulation and airway waterproofing need to be considered when adding a dryer. In this example, the cleaning cabin 3 is further provided with a drying air duct 10 , and the air outlet of the dryer 11 communicates with the inside of the cleaning cabin 3 through the drying air duct 10 . Because this shoe washing device adopts the vibration principle, it is necessary to ensure that the stroke of the brush 5 in the shoes vibrates and an opening is reserved on the upper part of the shoes, so this opening can be used as the air outlet of the cleaning cabin 3 to form a hot air passage.

[0045] Preferably, the positions of the drying air duct 10 and the dr...

no. 3 example

[0047] refer to Figure 12-14 , the purpose of this example is to provide a motor that can precisely control the opening and closing and angle of the machine cover 1 on the basis of the first embodiment, especially through a specific angle to make the shoe mouth of the shoe face down, so that the wet shoe is based on gravity. natural water control.

[0048] In order to realize this function, firstly, the cover 1 and the box body 2 need to be connected to form a rotating pair. At the same time, the cover 1 is also connected to the box body 2 through a strut 12 . On the one hand, one end of the strut 12 is connected with the machine cover 1 to form a revolving pair, so that its angle can be freely rotated; on the other hand, the other end of the strut 12 is connected to the lead screw nut 13 to form a revolving pair. The screw nut 13 is connected with the screw rod 14 to form a screw pair, and the screw rod 14 is connected with the box body 2 to form a rotary pair. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com