Oil mist pre-recovery device with compression structure and forced isolation function

A recovery device and oil mist technology, which is applied in the direction of combination device, separation method, and dispersed particle separation, can solve the problems of frequent replacement of consumables, pollution, poor filtration effect, etc., to reduce the cost of consumables and manpower for replacement of consumables, and to achieve high-efficiency filtration The effect of liquefaction collection and efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

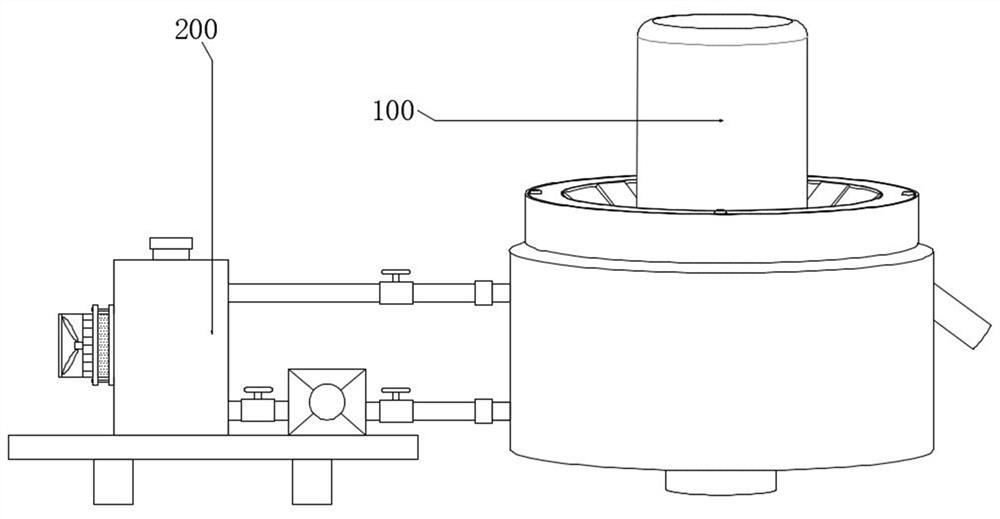

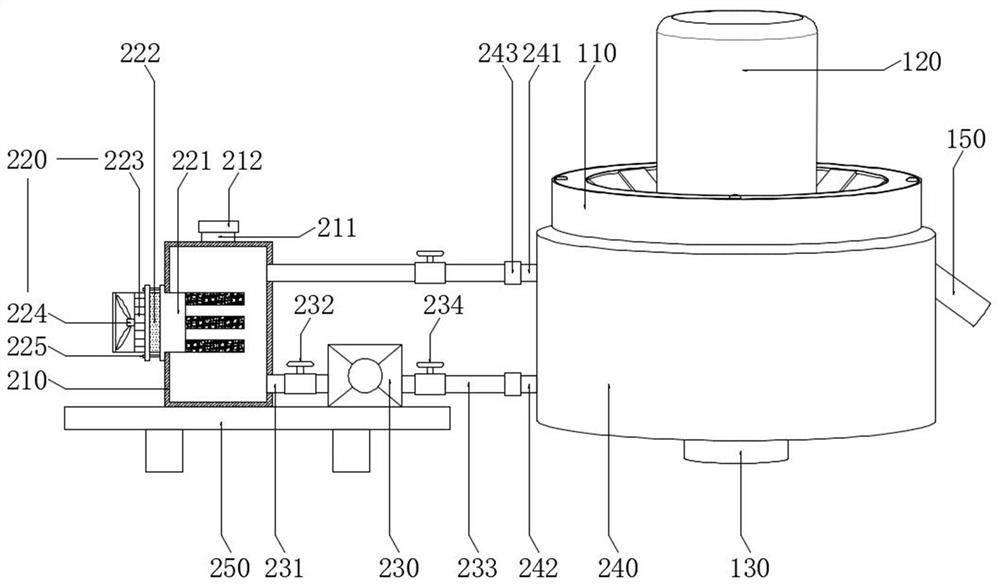

[0032] see Figure 1-3 , the present invention provides a technical solution: an oil mist pre-recovery device with a compression structure and forced isolation includes a liquefaction isolation mechanism 100 and a jacket water cooling mechanism 200 .

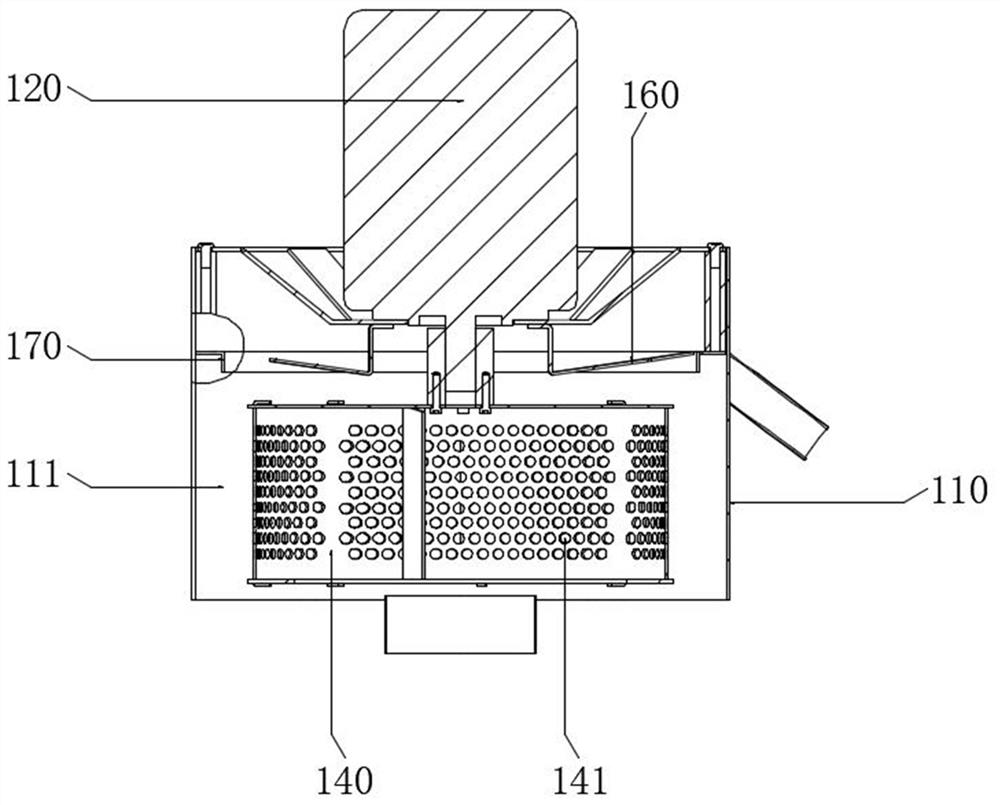

[0033] see figure 1 , figure 2 and image 3The liquefaction isolation mechanism 100 includes an oil mist channel housing 110, a motor 120, an air intake pipe 130, a porous impeller 140, an oil return pipe 150, an exhaust part 160 and a retaining ring 170, and the motor 120 is fixedly connected to the top of the oil mist channel housing 110, The motor 120 is screwed and fixedly connected to the top of the oil mist channel housing 110, the output end of the motor 120 is fixedly connected to the top of the porous impeller 140, the output end of the motor 120 is screwed and fixedly connected to the top of the porous impeller 140, and the porous impeller 140 is rotatably connected to the oil mist channel housing Inside 110, a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com