Single-spindle vibration exciter self-synchronizing synthesis linear track large-scale screening machine

A vibration exciter and self-synchronizing technology, applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of poor screen frame rigidity, short service life, unsatisfactory vibration force, etc., and achieve bearing service life Long, uniform and reasonable distribution, and uniform force on the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

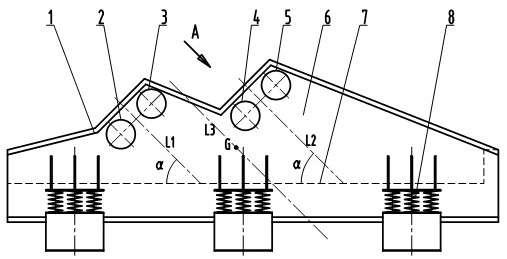

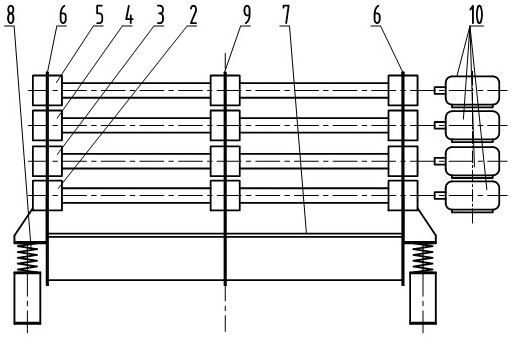

[0017] It includes a screen frame 1 , a screen surface 7 , a vibration exciter, a vibration-damping support device 8 and a motor transmission device 10 . The screen frame 1 is composed of a screen frame beam and a side plate riveted, and the side plate includes side plates 6 on both sides and a middle side plate 9 . The four sets of exciters correspond to each other and are installed on the side plates 6 on both sides and the middle side plate 9 of the screen frame 1. Each set of exciters is composed of three exciters, the side plates 6 on both sides and the middle side plate 9 One is installed on each, and the vibrators are connected by connecting shafts; each group of vibrators is connected with two motor drive devices 10 . One set of vibrator 2 and two sets of vibrator 3 are installed in the front row on the screen frame 1, the direction of rotation is opposite, the line of action to generate the resultant force is L1, and the angle α between L1 and the screen surface 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

| Length dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com