Method and Big Bag for Realizing Modular Permeable Reactive Wall

A permeable reaction wall and modular technology, which is applied in the restoration, packaging, and large-scale containers of contaminated soil, can solve the problems that restrict the promotion and use of groundwater permeable reaction walls, cannot achieve complex geological conditions restoration, and groundwater reaction wall restoration. Function passivation and other problems, to achieve the effect of low overall use cost, accelerated groundwater flow, and more environmentally friendly treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

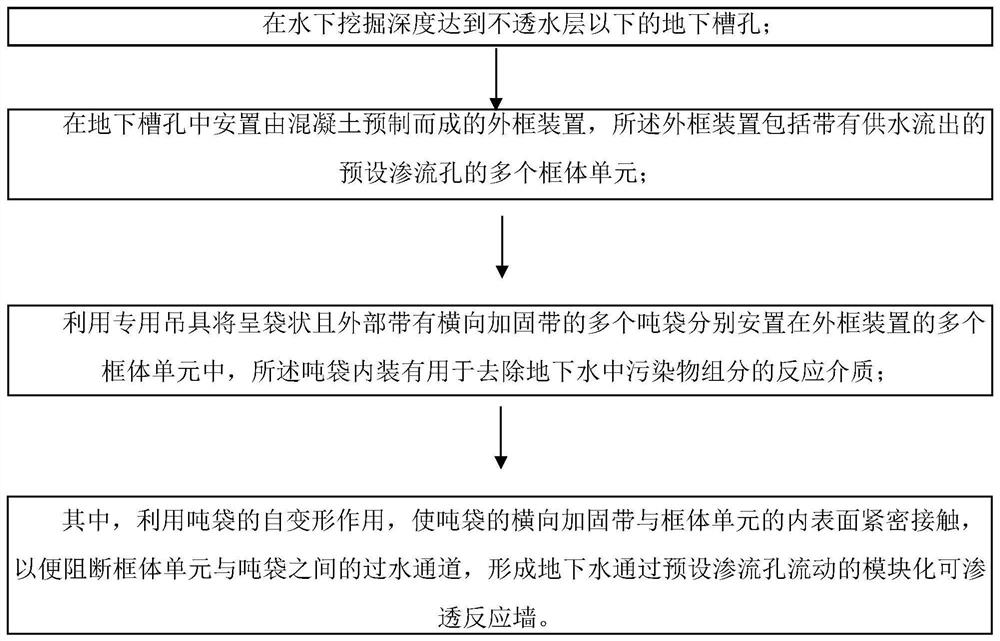

[0075] Such as figure 1 As shown, the flow chart of the method for realizing the modularized permeable reaction wall provided by the present invention, as can be seen from the figure, the method includes:

[0076] Underwater excavation of underground slots to a depth below the impermeable layer;

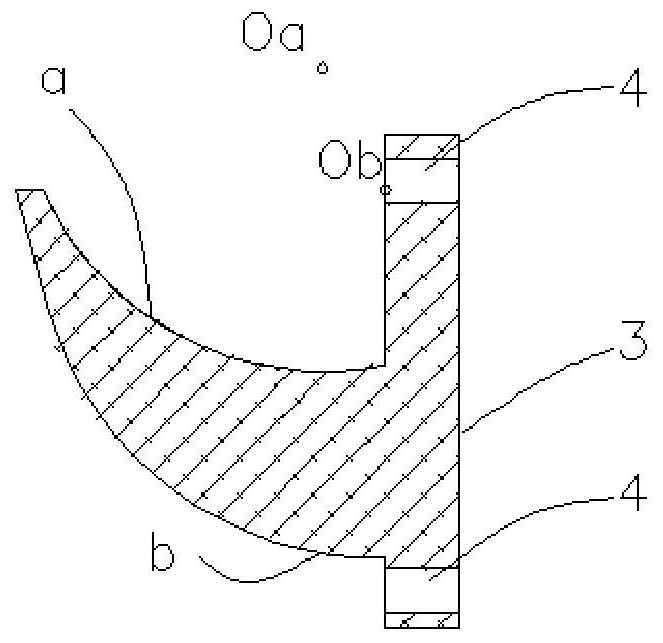

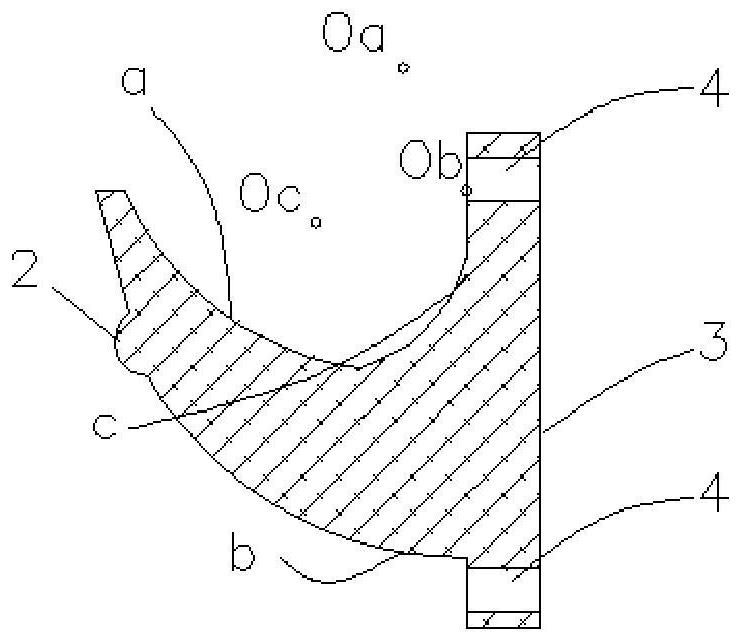

[0077] Prefabricating an outer frame device made of concrete in the underground tank, the outer frame device includes a plurality of frame units with preset seepage holes for water supply to flow out;

[0078] Use a special sling to place a plurality of bag-shaped bags with external transverse reinforcement belts in multiple frame units of the outer frame device. The reaction medium used to remove pollutant components in groundwater is installed in the big bags;

[0079] Among them, the self-deformation effect of the big bag is used to make the transverse reinforcement belt of the big bag closely contact with the inner surface of the frame unit, so as to block the water passage betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com