Electric furnace heating assembly assembling line

A heating component and assembly line technology, applied in the direction of assembly machines, transportation and packaging, conveyors, etc., can solve the problems of inconsistent product quality, large manpower consumption, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

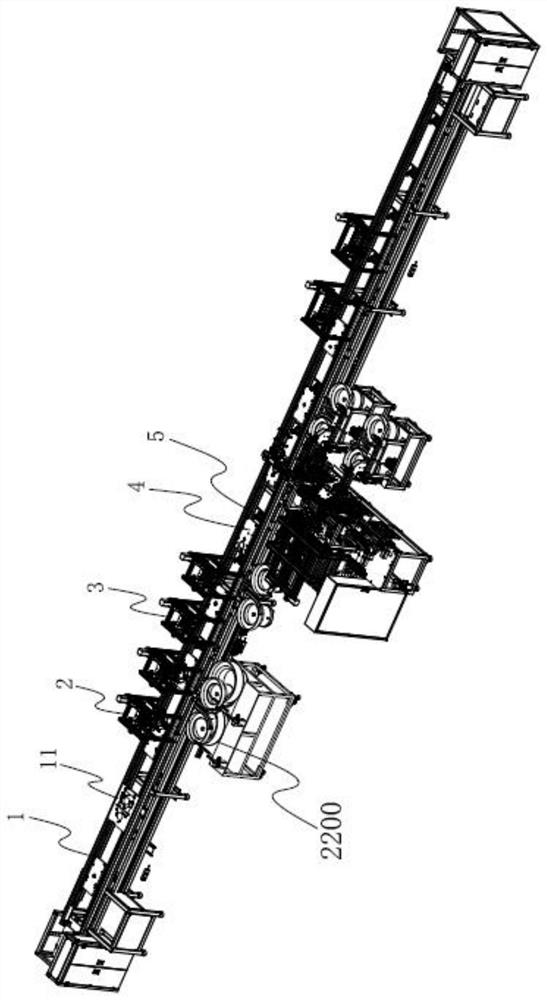

[0030] see Figure 1-Figure 9 , an electric furnace heating component assembly line, comprising:

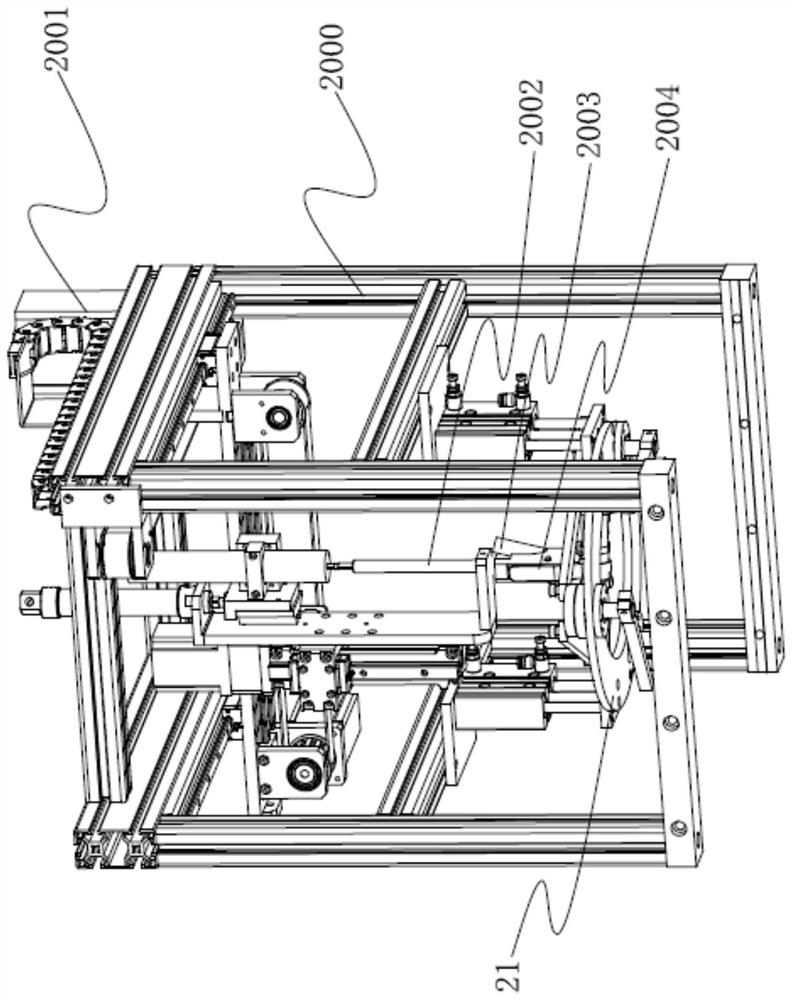

[0031] Circular conveyor line 1 and the automatic screw loading station 2, automatic nut loading station 3, position adjustment station 4, upper cover assembly installation station 100 and bolt locking station 8 arranged along the circular conveyor line 1 in sequence;

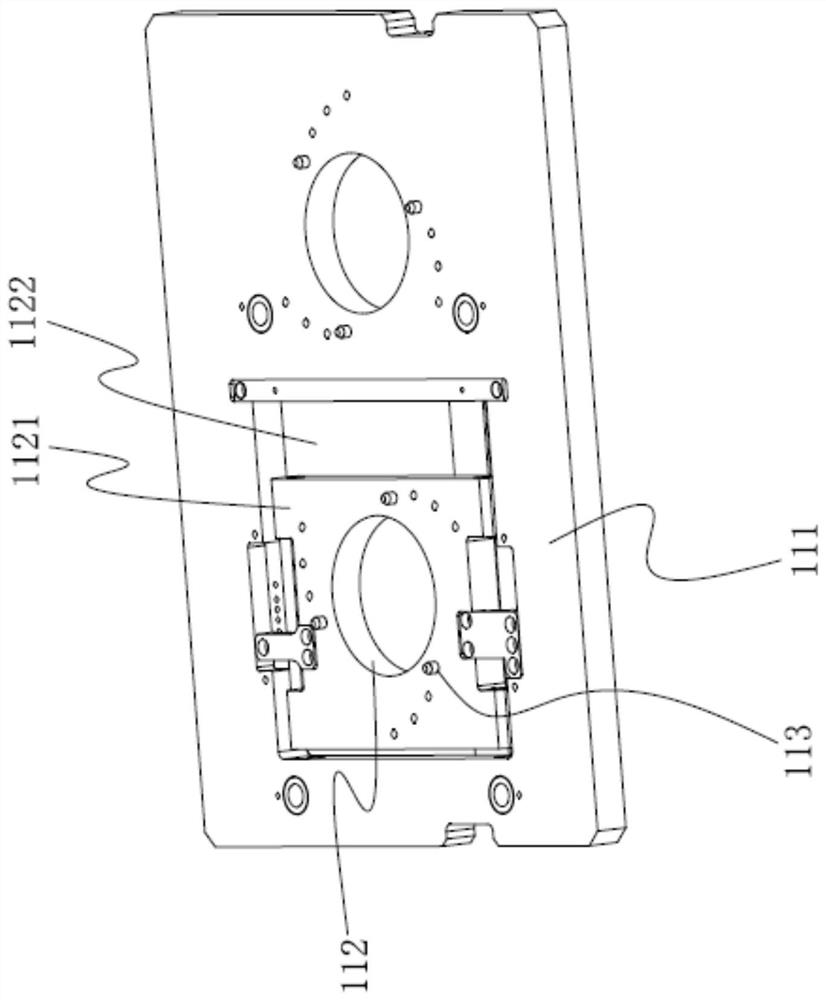

[0032] A moving bracket 11, which is arranged on the circulating conveying line 1 and is driven by the circulating conveying line 1 to move, and the moving bracket 11 is used to place parts;

[0033] Automatic loading screw station 2, which automatically screw the parts on the mobile bracket 11;

[0034] Automatic nut loading station 3, which is used to nut the parts on the mobile bracket 11;

[0035] Position adjustment station 4, the position adjustment station 4 is used to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com