Machine tool panel operation manipulator based on circumferential motion

A machine tool panel, circumferential motion technology, applied in the directions of manipulators, metal processing mechanical parts, large fixed members, etc., can solve problems such as low transmission efficiency, inability to provide accurate force control, and complex transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with the best embodiment.

[0028] A machine tool panel operating manipulator based on circumferential motion, characterized in that:

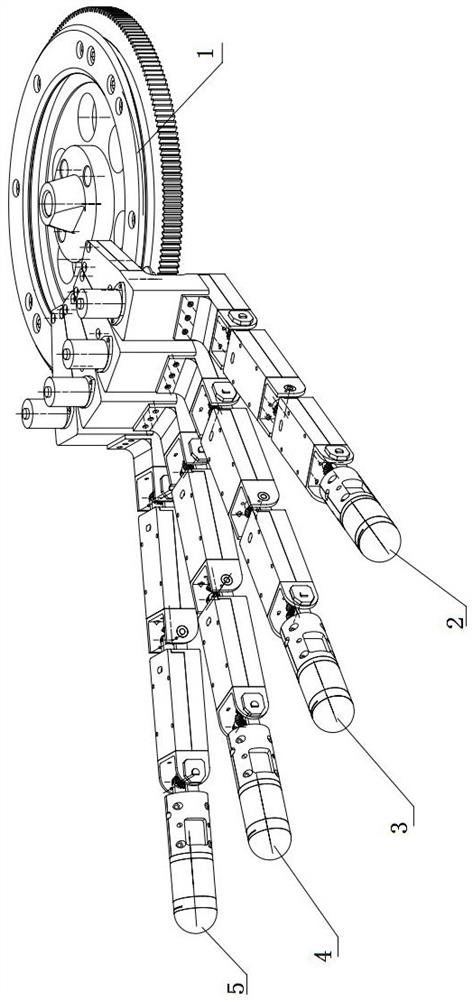

[0029] Such as figure 1As shown, the device is composed of a main body module, a first finger module, a second finger module, a third finger module and a fourth finger module. The 2-first finger module and the 1-body module are driven by gears, so that the 2-first finger module can perform circular motion around the 1-body module. The 3-second finger module and the 1-body module are driven by gears, so that the 3-second finger module can move around the 1-body module without colliding with the 2-first finger module. The 4-third finger module and the 1-body module are driven by gears, so that the 4-third finger module can go around the 1-body without colliding with the 2-first finger module and 3-second finger module The module makes a circular motion. The 5-fourth finger module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com