Flexible joints based on rolling contact and continuous body robots with their continuous body robots

A technology of flexible joints and rolling contact, which is applied in the direction of joints, manipulators, manufacturing tools, etc., can solve the problems of small axial bearing capacity, small rotation angle, and excessive size, and achieve the effect of increasing axial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

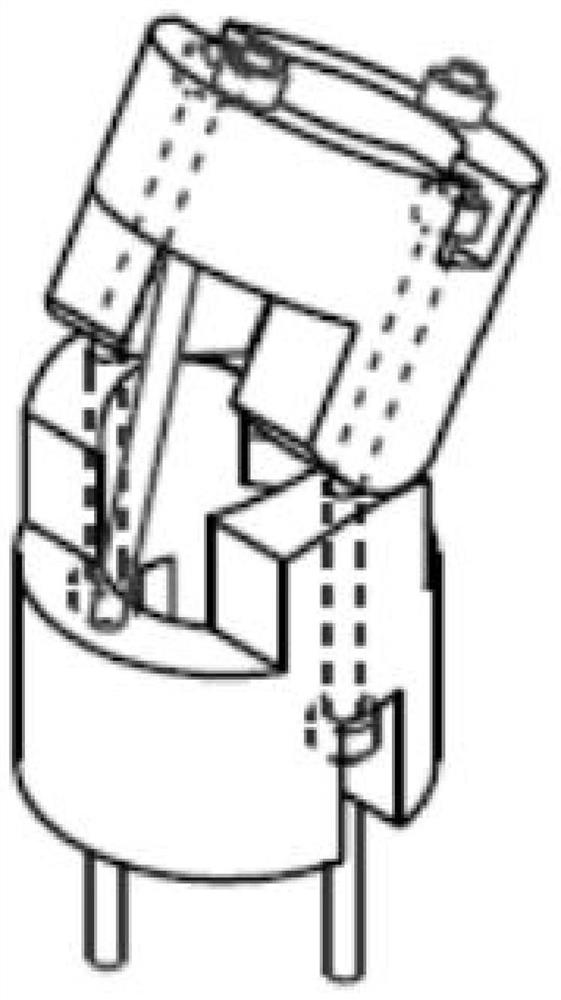

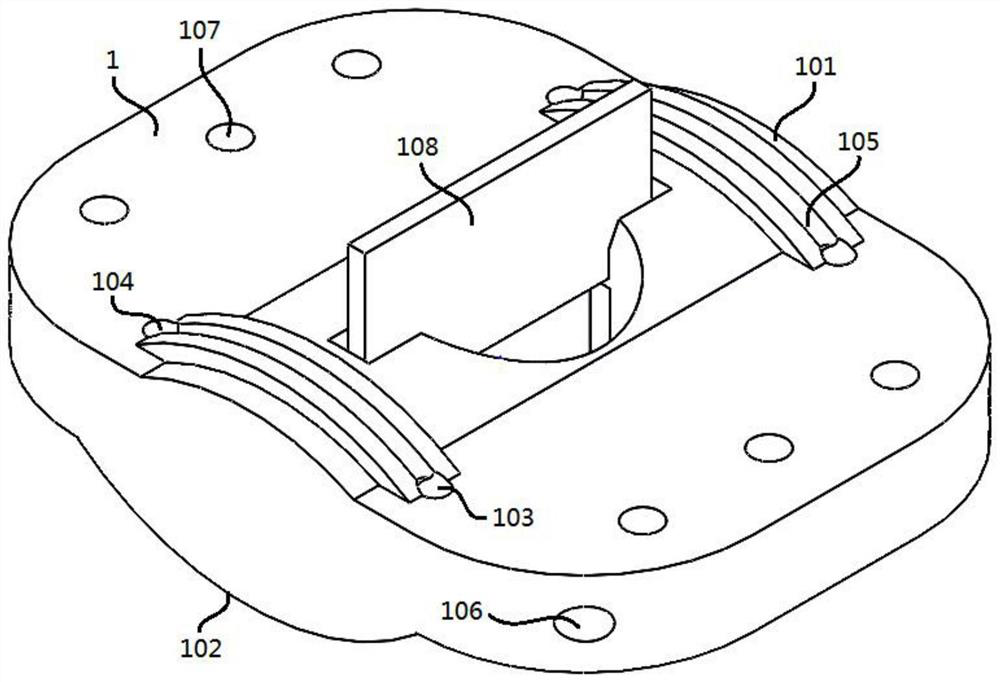

[0080] Embodiment 1 of the present invention discloses a flexible joint based on rolling contact, the flexible joint includes:

[0081] Two interconnected rolling elements 1;

[0082] The rolling body 1 has a first contact surface 101 located at the upper end of the rolling body 1 and a second contact surface 102 located at the lower end of the rolling body 1;

[0083] Both the first contact surface 101 and the second contact surface 102 are configured as arc structures;

[0084] The two rolling elements 1 are formed into a rolling connection through the first contact surface 101 and the second contact surface 102;

[0085] A central reed 108 is plugged into the middle of the rolling body 1, and the central reed 108 can slide relative to the rolling body 1;

[0086] The central reed 108 provides a restoring moment after the adjacent rolling elements 1 roll.

[0087] Specifically, the flexible joint disclosed in Embodiment 1 realizes a pure rolling connection through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com