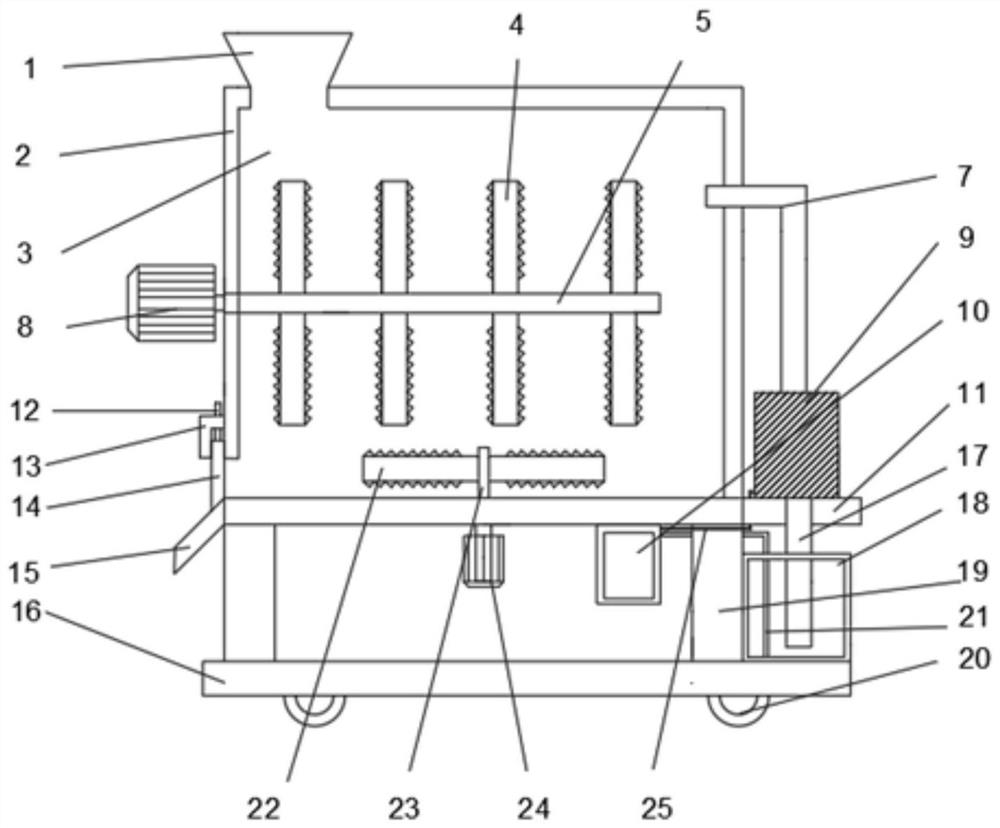

Concrete mixer for construction site

A technology for concrete mixers and construction sites, applied in cement mixing devices, clay preparation devices, mixing operation control, etc., can solve problems such as excessive water addition, influence on use, and insufficient water addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

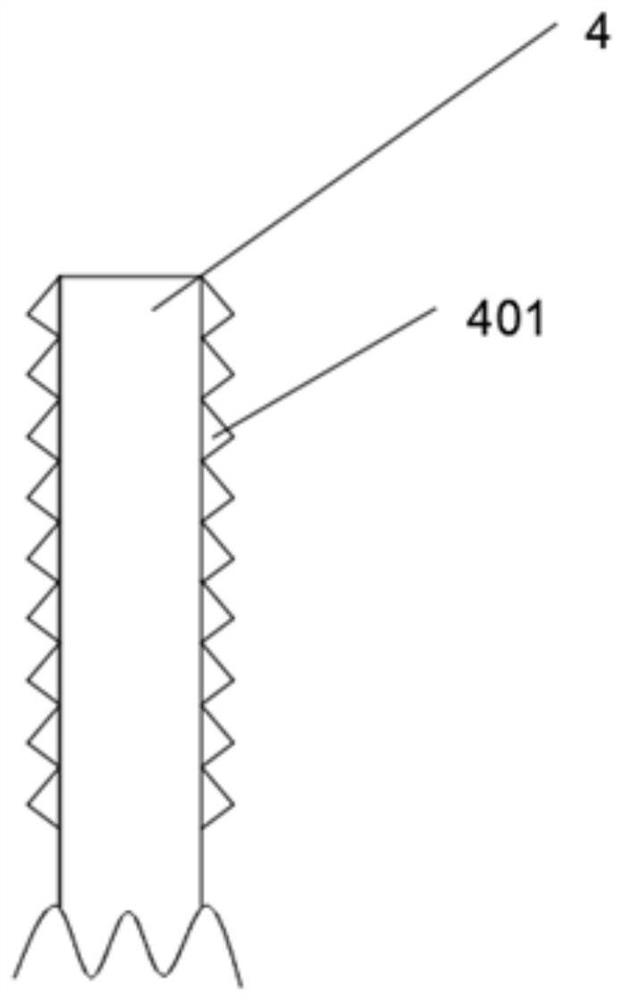

[0023] As a preferred embodiment of the present invention, the water injection pipe 7 is a steel water pipe, which can prevent the bending of the water injection pipe from affecting water injection, and the diameter of the water injection pipe is between five centimeters and eight centimeters.

[0024] As a preferred embodiment of the present invention, the discharge sliding plate 15 is provided with a groove matching the blocking door 14, and the blocking door 14 can be embedded inside the discharging sliding plate 15 to effectively prevent the blocking door 14 from sliding down.

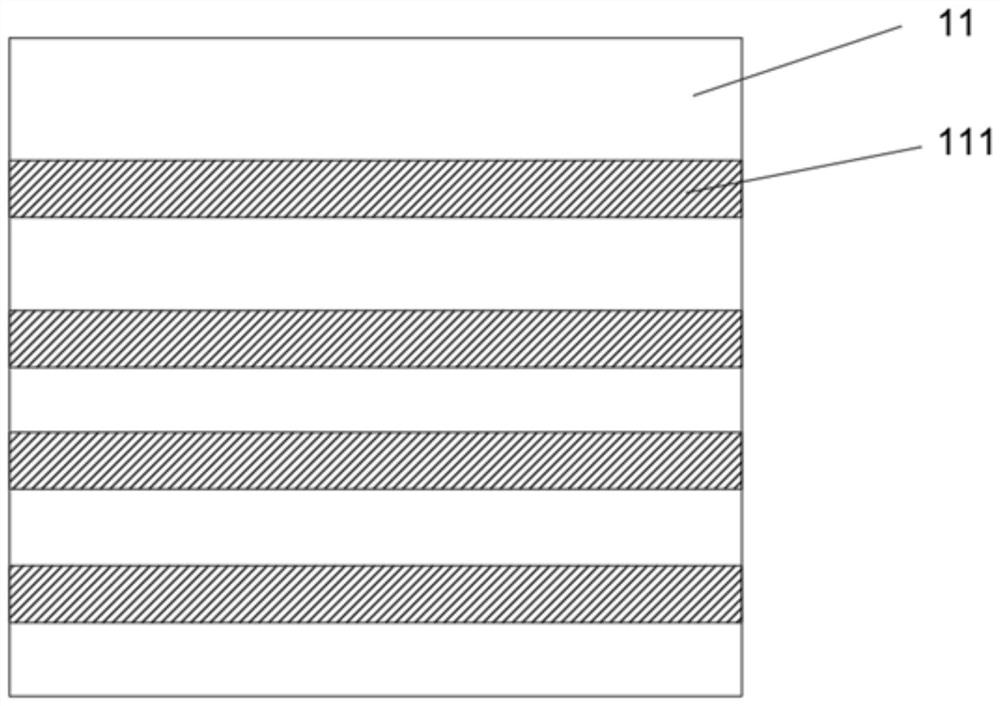

[0025] As a preferred embodiment of the present invention, there are four induction belts 111 on the weight induction plate 11 , and the induction belts can sense the net weight of raw materials in the outer box 2 for stirring.

[0026] As a preferred embodiment of the present invention, the induction control panel 10 is electrically connected to the water pump 9 through the connecting wire 25, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com