Accurate material feeding system and method for ropy solid-liquid mixing flavoring agent

A solid-liquid mixing and flavoring technology, which is applied in the direction of mixers, liquid materials, chemical instruments and methods, etc., can solve problems such as inaccurate feeding, uneven mixing, and decreased taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

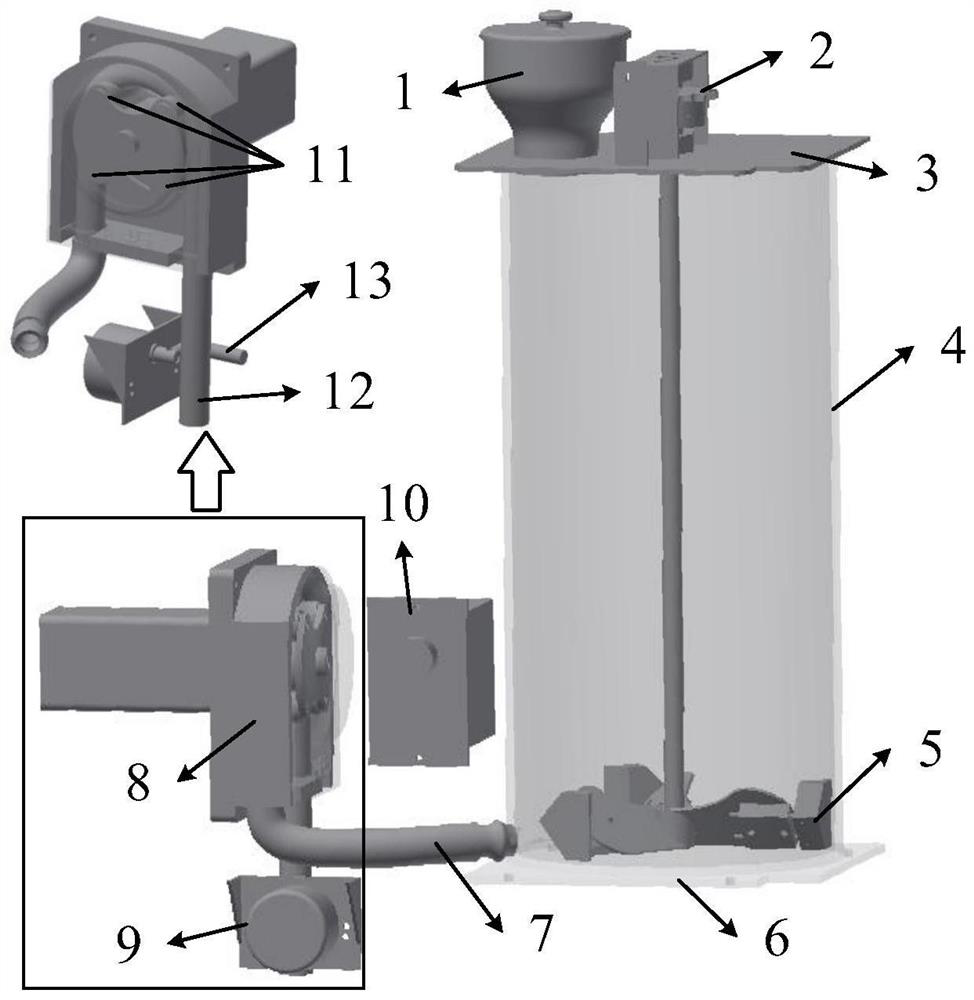

[0044] figure 1 It is a schematic diagram of the precise feeding system for viscous solid-liquid mixed flavoring. The system is mainly composed of feed inlet 1, seasoning barrel 4, agitator 5, gravity sensor 6, peristaltic valve 8, flow stop motor 9 and so on.

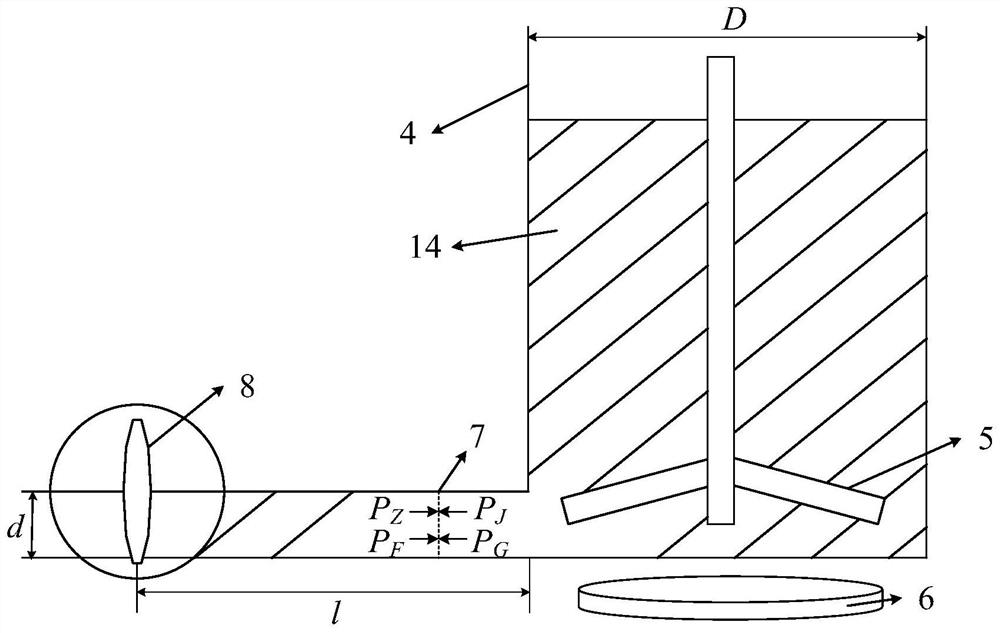

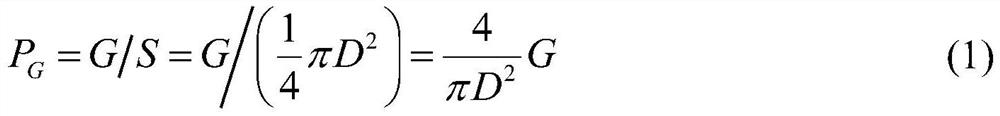

[0045] figure 2 It is a schematic diagram of the precise feeding calculation principle of viscous solid-liquid mixed flavoring agent. Solve the pressure balance relationship at the discharge port caused by factors such as the weight of the flavoring agent, viscosity, stirring, and the internal pressure of the valve, and determine the internal pressure of the valve that is self-adjusting with the amount of material that needs to be fed and the remaining amount of the flavoring agent, and finally realize the viscosity Precise feeding process of solid-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com