Limiting mechanism and limiting device

A technology of limit mechanism and limit device, applied in the directions of transportation and packaging, packaging, external frame, etc., can solve the problems of unstable limit and large degree of freedom, so as to improve safety and reliability, increase contact area, limit The effect of safe and stable disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

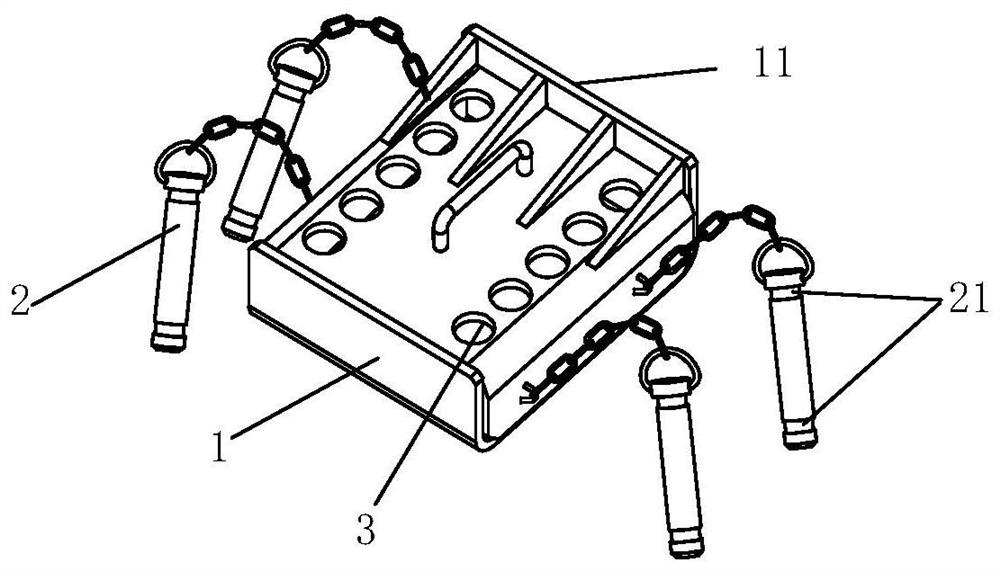

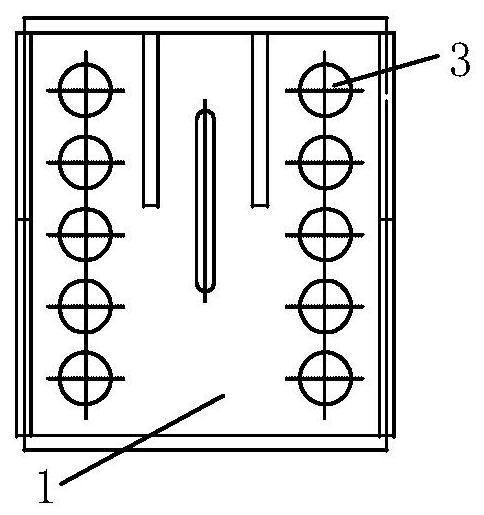

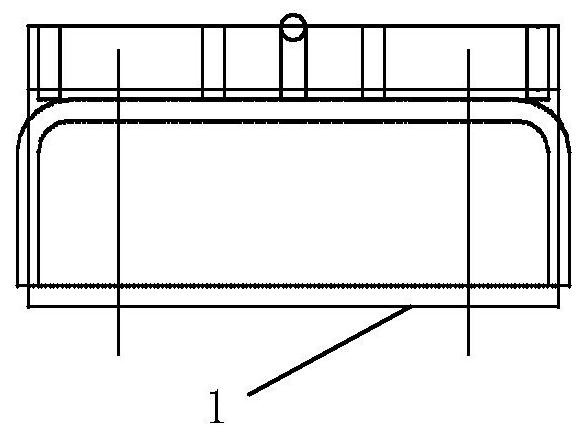

Embodiment 1

[0068] In this embodiment, the limiting beam 4 and the limiting block 1 are detachable structures. Such as Figure 5 The limiting block 1 is provided with two rows of pin holes 3, each row of pin holes 3 corresponds to two pins 2, the first bearing surface 11 is located at one end of the two rows of pin holes 3, and the limiting block 1 is provided with a limiting plate 12, The limit plate 12 is used to limit the limit block 1 and the upper limit beam 4 . Limiting plate 12 is an upward V-shaped opening made up of two plates. Limiting plate 12 is located between the two rows of pin holes 3 on the limiting block 1. The limiting plate 12 is provided with a third row of pin holes 3. The pins 2 is connected to both sides of the limit block 1 by a chain. Such as Figure 6 A limit beam 4 is shown, the limit beam 4 includes a beam 43, a horizontal plate 44 and a vertical plate 45, wherein the beam 43 is clamped on the horizontal plate 44 through two reinforcing plates 46, and the r...

Embodiment 2

[0070] In this embodiment, the limiting beam 4 and the limiting block 1 are detachable structures. Such as Figure 8 As shown, the limiting block 1 includes two connecting plates 13 at an angle and a receiving plate 14, the two connecting plates 13 are vertically connected to the receiving plate 14, and among the two connecting plates 13, one connecting plate 13 is connected to the base plate 100 is fitted and connected, and the other connecting plate 13 is fitted and connected with the transverse plate 44 of the limit beam 4 . Wherein, the pins 2 are connected by chains on the two connecting plates 13, four pins 2 are connected on the lower connecting plate 13 for pinning the lower connecting plate 13 on the base plate 100, and the connecting pins 2 on the upper connecting plate 13 are used for The limit beam 4 is pinned to the upper connecting plate 3 . The receiving plate 14 is a vertical plate, and when in use, the outer surface of the receiving plate 14 is the first bea...

Embodiment 3

[0073] In this embodiment, the limiting beam 4 and the limiting block 1 are integrally structured. Such as Figure 13 As shown, the outer surface of the receiving plate 14 is the first bearing surface 11, the upper connecting plate 13 of the limiting block 1 and the two ends of the transverse plate 44 of the limiting beam 4 are integrally structured plates, and the transverse beam 43 is fixed by a reinforcing plate 46 On the horizontal plate 44, the rear side of the cross beam 43 is the second bearing surface 41, the vertical plate 45 is connected to the horizontal plate 44 and the rear surface of the vertical plate 45 is coplanar with the rear side of the cross beam 43, and the lower connecting plate of the limiting block 1 The bottom of 13 is provided with pins 2, the arrangement of the pins 2 is the same as the arrangement of the first through hole 1001 on the substrate 100, the lower connecting plate 13 can be directly inserted into the first through hole 1001 and locked t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com