Multi-tonnage large-scale lifting device with lever push-pull structure

A lifting device and large-scale technology, applied in the direction of lifting devices, hoisting devices, etc., can solve the problems of equal quantity and speed, low product grade, and difficulty in borrowing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

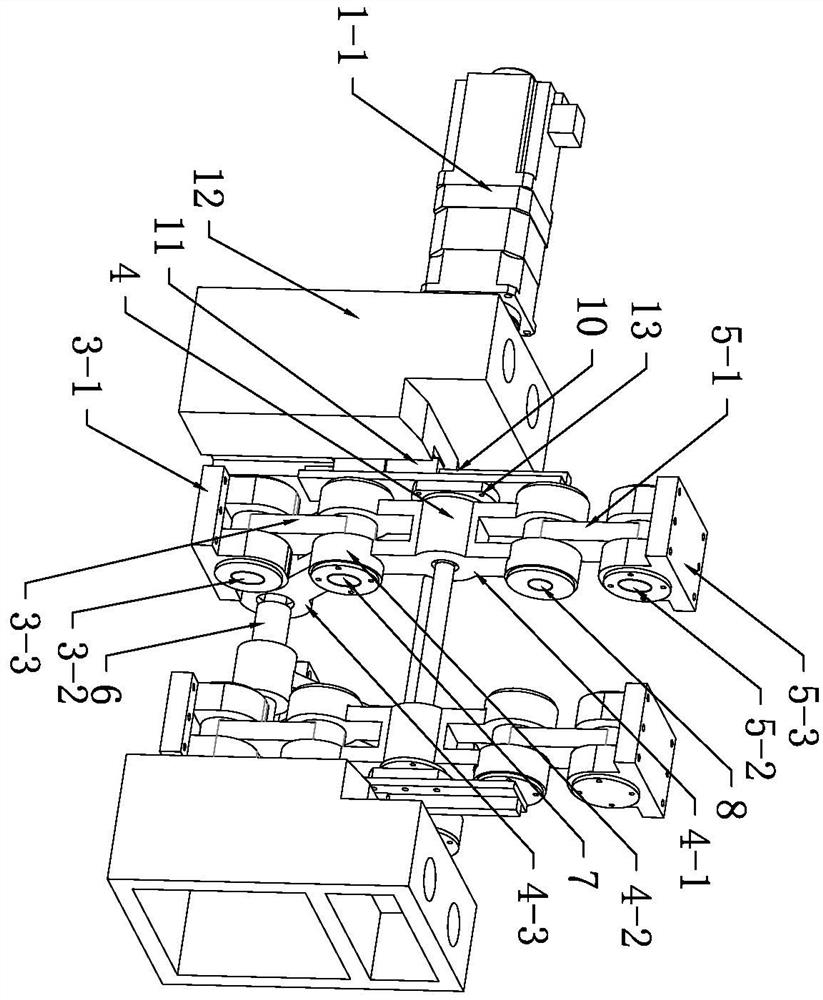

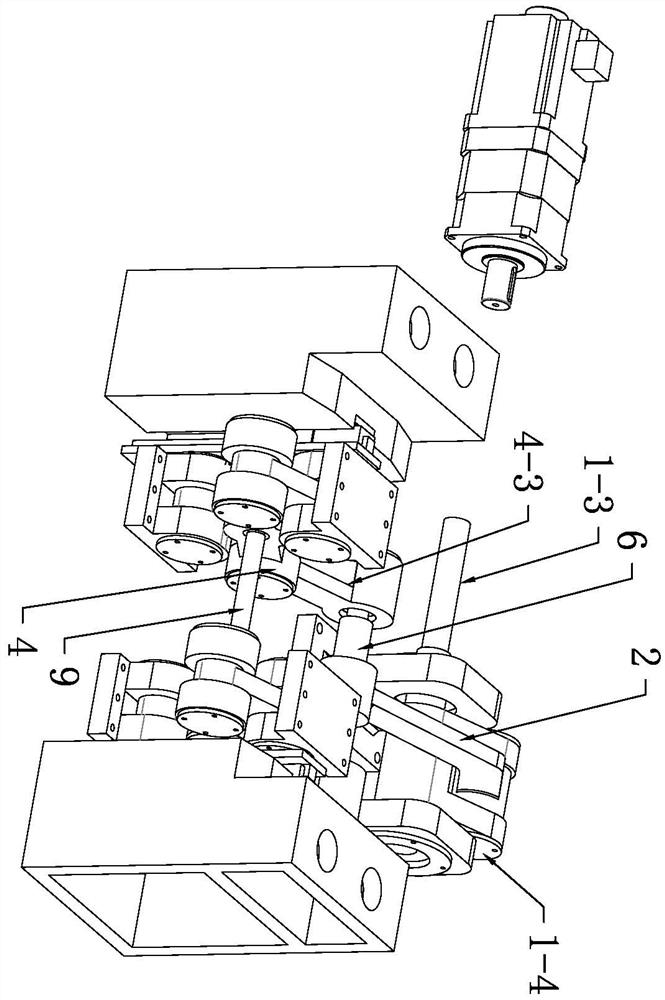

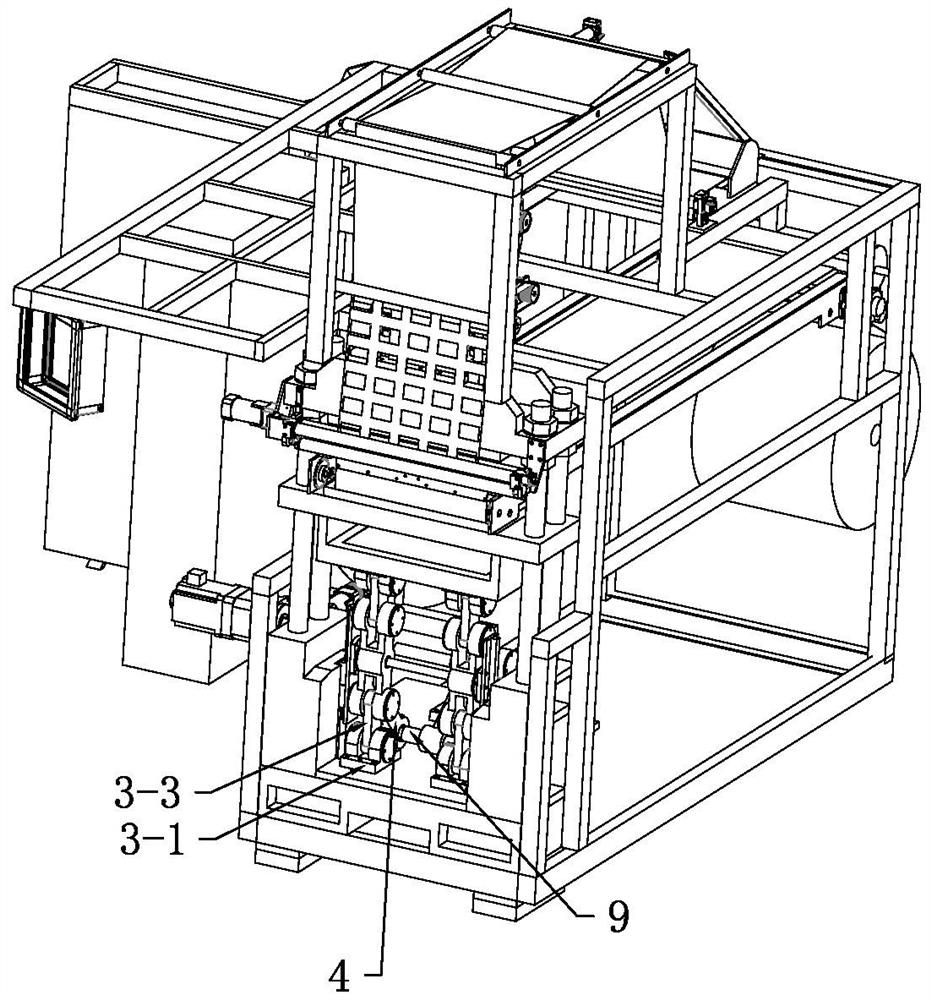

[0050] see Figures 1 to 5 The multi-tonnage large-scale lifting device of the lever push-pull structure of the present embodiment includes an upper rotating support base 5-3, a lower rotating support base 3-1, an upper lifting motion crank 5-1, a lower lifting motion crank 3-3, a positioning Lifting shaft, vertical lifting limit slider 10, lever pressing and pulling lifting crank 2, forward and reverse rotation driving crank 1-4, positioning and rotating slide lever crank 4, positioning lifting shaft 9 and push-pull drive mechanism, the push-pull drive mechanism is a servo motor 1-1, the servo motor 1-1 is equipped with a reducer 1-2, and the forward and reverse rotation driving crank 1-4 is fastened to the drive shaft 1-3 of the reducer 1-2.

[0051] In this embodiment, the lower end of the lower lifting crank 3-3 is relatively rotatably connected to the lower rotating support base 3-1 through a hinge shaft, and the upper end of the lower lifting crank 3-3 is hinged to the p...

Embodiment 2

[0056] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the forward and reverse rotation driving crank 1-4 can also be an eccentric wheel.

Embodiment 3

[0058] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. see Image 6 , The difference between this embodiment and Embodiment 1 is that the push-pull drive mechanism includes a motor, a drive shaft 1-5, a driving gear 1-6, a rack 1-7 and a connecting piece 1-8, and the motor is equipped with a reducer , the drive shaft 1-3 of the reducer is used as the drive shaft 1-5 or the drive shaft 1-5 is connected with the drive shaft 1-3 of the reducer through a coupling. The motor drives the drive shaft 1-5 to rotate, the driving gear 1-6 is installed on the drive shaft 1-5 and rotates with the drive shaft 1-5, the gear and the rack 1-7 are engaged for transmission, and one end of the rack 1-7 is fixedly connected with Connecting piece 1-8, connecting piece 1-8 is relatively rotatably connected with the rear end of lever pressing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com