Automatic filling and cap screwing integrated machine in bottled chili sauce production process

A production process and automatic filling technology, applied in bottling machines, bottle filling, threaded bottle caps, etc., can solve the problems of low work efficiency, long time-consuming, slow rotation process, etc., to improve the capping speed and ingenious design , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

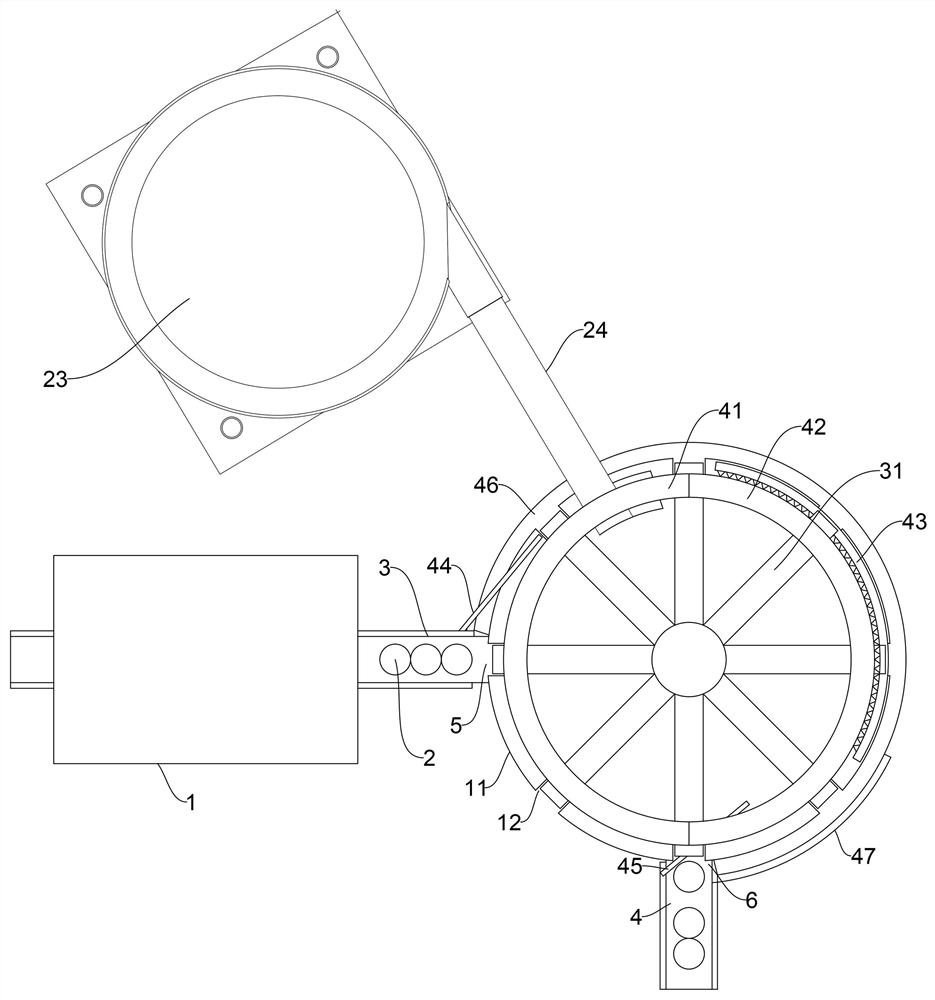

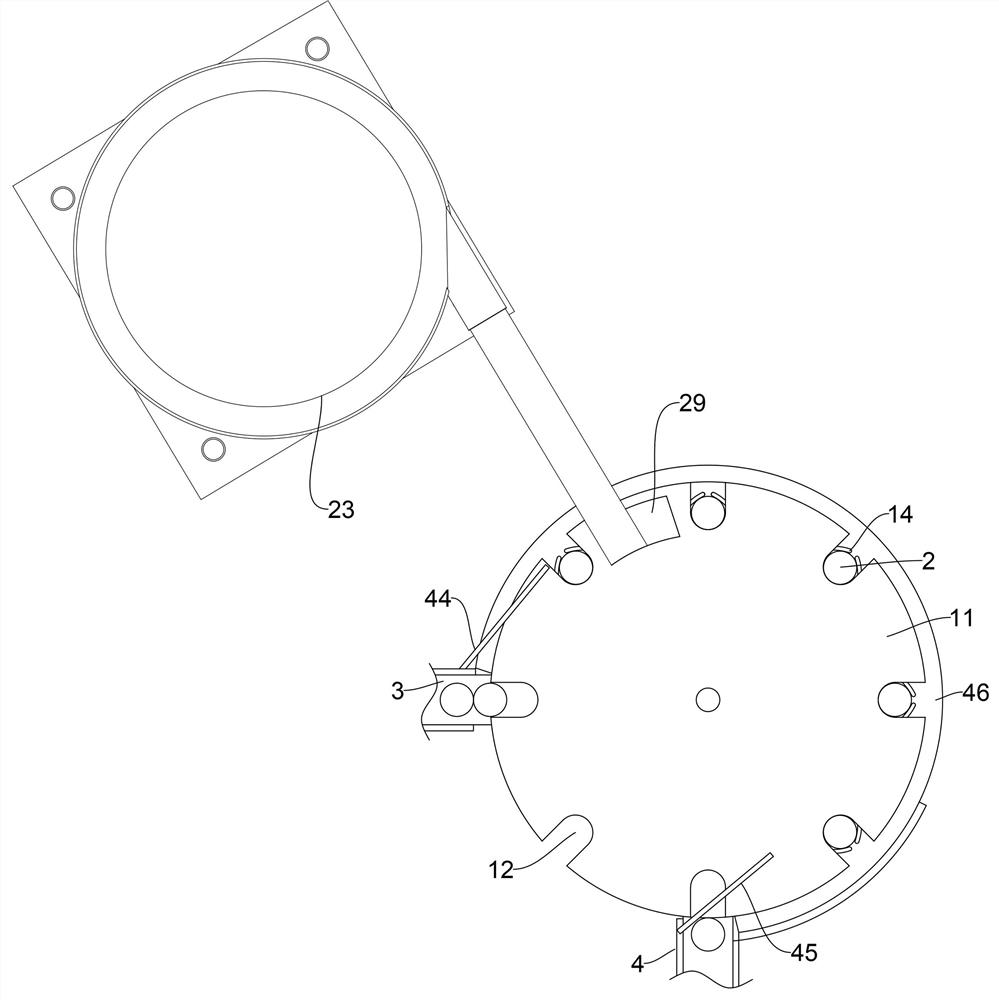

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-10 Shown: an automatic filling and capping integrated machine in the production process of bottled chili sauce, comprising a filling device 1, a capping device, a bottle body 2, a first conveyor belt 3, and a second conveyor belt 4, and the capping device has advanced Bottle station 5, capping station 6 and bottle outlet station 7, the first conveyor belt 3 transports the bottle body 2 filled by the filling device 1 to the bottle inlet station 5, and the second conveyor belt 4 The bottle station 7 accepts the screwed bottle body 2;

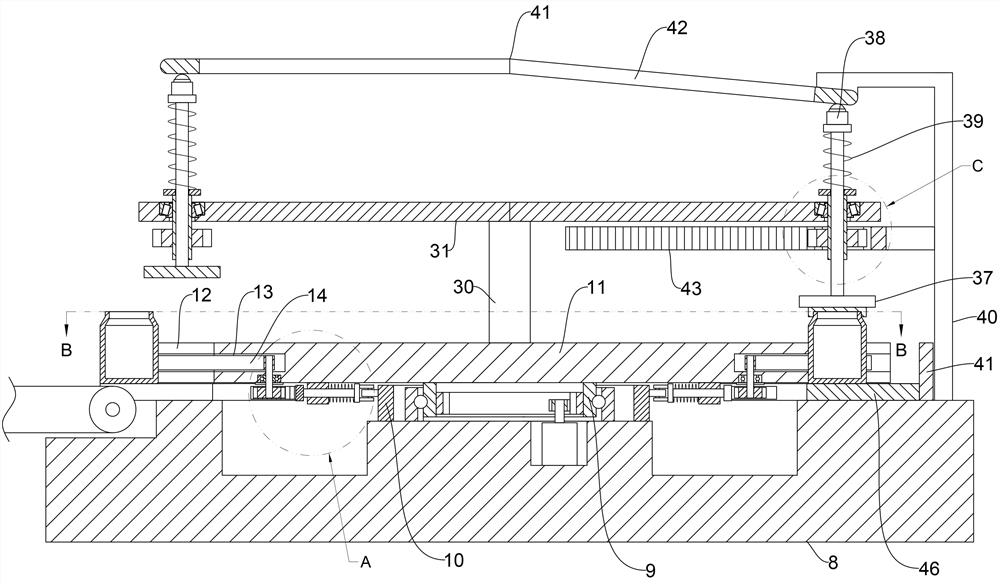

[0027] Such as figure 2 As shown, the capping device includes a base 8, on which an electric turntable 9 and an eccentric ring 10 located at the periphery of the electric turntable 9 are fixedly installed, and a cap turntable 11 is installed on the electric turntable 9, and the base circle axis of the eccentric ring 10 is in line w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com