Nitrogen-containing compound and electronic component and electronic device using the same

A nitrogen compound, electronic component technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of increased device operating voltage, reduced device luminous efficiency, and unfavorable energy saving, and can reduce operating voltage and enhance electronic conduction. rate, enhance the effect of injection and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

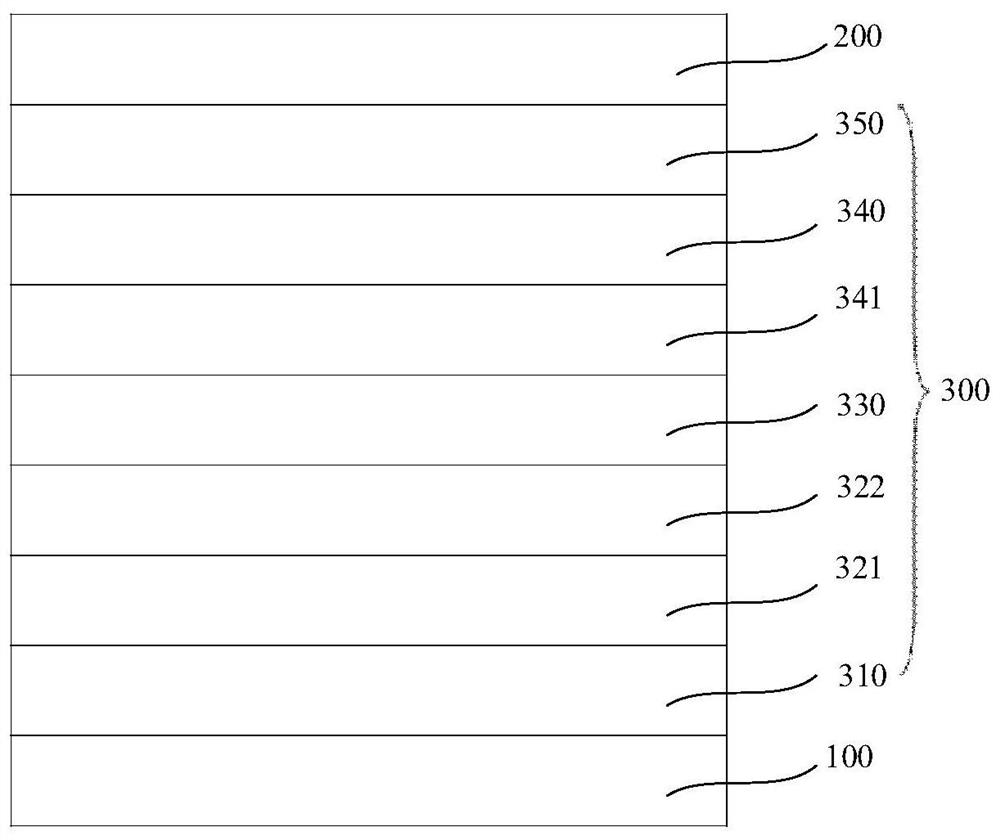

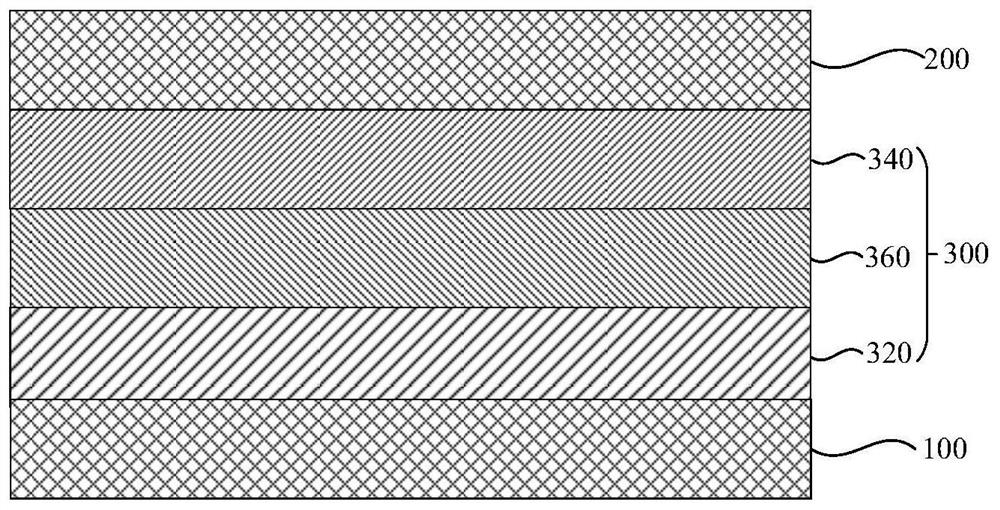

[0245] Embodiment 1 blue organic electroluminescent device

[0246] The anode was prepared by the following process: the thickness was The ITO substrate (manufactured by Corning) was cut into a size of 40mm×40mm×0.7mm, and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by photolithography process, using ultraviolet ozone and O 2 :N 2 Plasma surface treatment was performed to increase the work function of the anode (experimental substrate) and to remove scum.

[0247] F4-TCNQ was vacuum evaporated on the experimental substrate (anode) to form a thickness of The hole injection layer (HIL), and HT-01 is evaporated on the hole injection layer to form a thickness of hole transport layer.

[0248] EB-01 was vacuum evaporated on the hole transport layer to form a thickness of electron blocking layer.

[0249] On the electron blocking layer, BH-01 and BD-01 are co-evaporated at a ratio of 98%: 2%, forming a thickness of org...

Embodiment 2~30

[0255] The organic electroluminescence device was prepared by the same method as in Example 1, except that the nitrogen-containing compound A-1 was replaced with the nitrogen-containing compounds shown in Table 9 when preparing the electron transport layer.

Embodiment 31

[0257] The organic electroluminescence device is prepared by the same method as in Example 1, the difference is only that, when forming the hole blocking layer, the nitrogen-containing compound B-11 of the present application is used instead of the compound ET-01, and when forming the electron transport layer , the nitrogen-containing compound A-1 of the present application was replaced by compound ET-01.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap