A kind of method utilizing salt eutectic method to prepare anti-retrogradation amylose

An amylose and anti-retrogradation technology, which is applied in the field of preparing anti-retrogradation amylose, can solve problems such as changing the taste of amylose solution, achieve the effects of weakening the retrogradation property and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

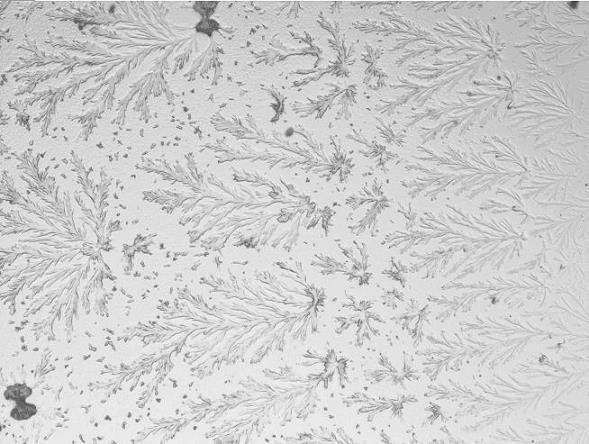

Image

Examples

Embodiment 1

[0014] (1) Dissolve 50g of table salt in 1L of tap water to make an aqueous solution with a salt content of 5% (g / v), and add wheat amylose, salt When dissolving with wheat amylose in water, the stirrer speed was 150 rev / min, and the stirring time was 5 minutes. Wheat amylose was dissolved in saline and cultured at 4°C for 6 hours, 3 times the volume of absolute ethanol was added to precipitate the amylose, centrifuged, washed with water and desalted to obtain anti-retrogradation amylose. The centrifugation speed is 3500 rpm for 20 minutes during the process of ethanol precipitation of starch and water washing for desalination, and the amount of water added for desalination is 3 times the amount of wet starch. The resulting anti-retrogradation amylose was air-dried at 60 °C to constant weight to obtain solid starch. Mix 100 grams each of wheat original amylose and anti-retrogradation wheat amylose with water to make starch milk with a concentration of 10% (g / v), gelatinize at...

Embodiment 2

[0017] (1) Dissolve 80g of table salt in 1L of tap water to make an aqueous solution with a salt content of 8% (g / v), and add sweet potato amylose, salt When dissolving sweet potato amylose in water, the mixer speed was 150 rpm, and the stirring time was 10 minutes. Sweet potato amylose was dissolved in saline and cultured at 10°C for 12 hours, 3 times the volume of absolute ethanol was added to precipitate the amylose, centrifuged, washed with water and desalted to obtain anti-retrogradation sweet potato amylose. The centrifugation speed is 3500 rpm for 20 minutes during the process of ethanol precipitation of starch and water washing for desalination, and the amount of water added for desalination is 3 times the amount of wet starch. The resulting anti-retrogradation sweet potato amylose was air-dried at 60 °C to constant weight to obtain solid starch. Mix 100 grams each of sweet potato amylose and anti-retrograded sweet potato amylose with water to make starch milk with a ...

Embodiment 3

[0020] (1) Dissolve 200g of table salt in 1L of tap water to make an aqueous solution with a salt content of 20% (g / v), and add corn amylose, salt When dissolving amylose and corn starch in water, the mixer speed was 150 rpm, and the stirring time was 20 minutes. Dissolve corn amylose in saline and culture at 40°C for 48 hours, add 3 times the volume of absolute ethanol to precipitate the amylose, centrifuge, wash with water to remove salt, and obtain anti-retrogradation corn amylose. The centrifugation speed is 3500 rpm for 20 minutes during the process of ethanol precipitation of starch and water washing for desalination, and the amount of water added for desalination is 3 times the amount of wet starch. The obtained anti-retrogradation corn amylose was air-dried at 60 °C to constant weight to obtain solid starch. Mix 100 grams each of corn original amylose and anti-retrograded corn amylose with water to make starch milk with a concentration of 10% (g / v), gelatinize at 90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com