Method for separating butane and butene by using multiple mixed solvent

A technology for mixing solvents and separating butane, which is applied in distillation purification/separation, bulk chemical production, organic chemistry, etc. It can solve the problems of low tray efficiency, low solubility, and low separation ability, so as to reduce energy consumption and reduce Solvent ratio, effect of increasing relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

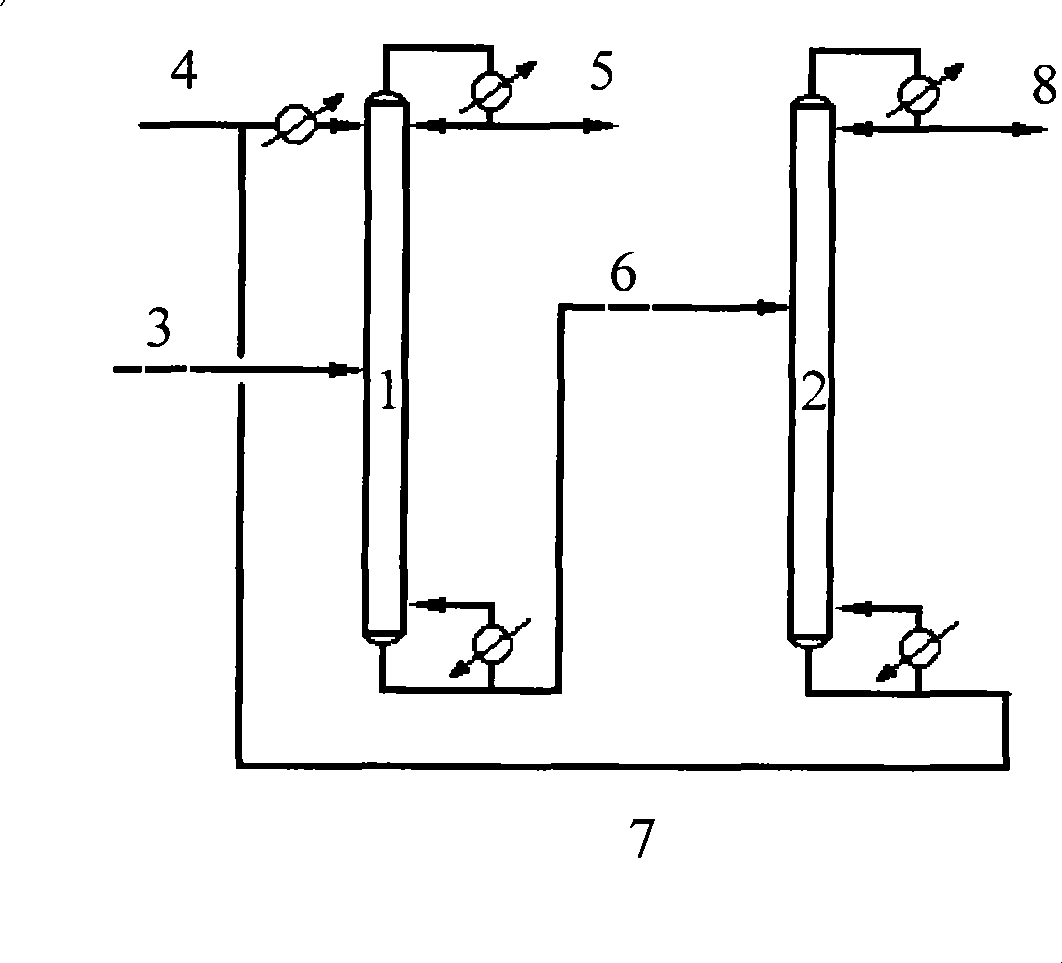

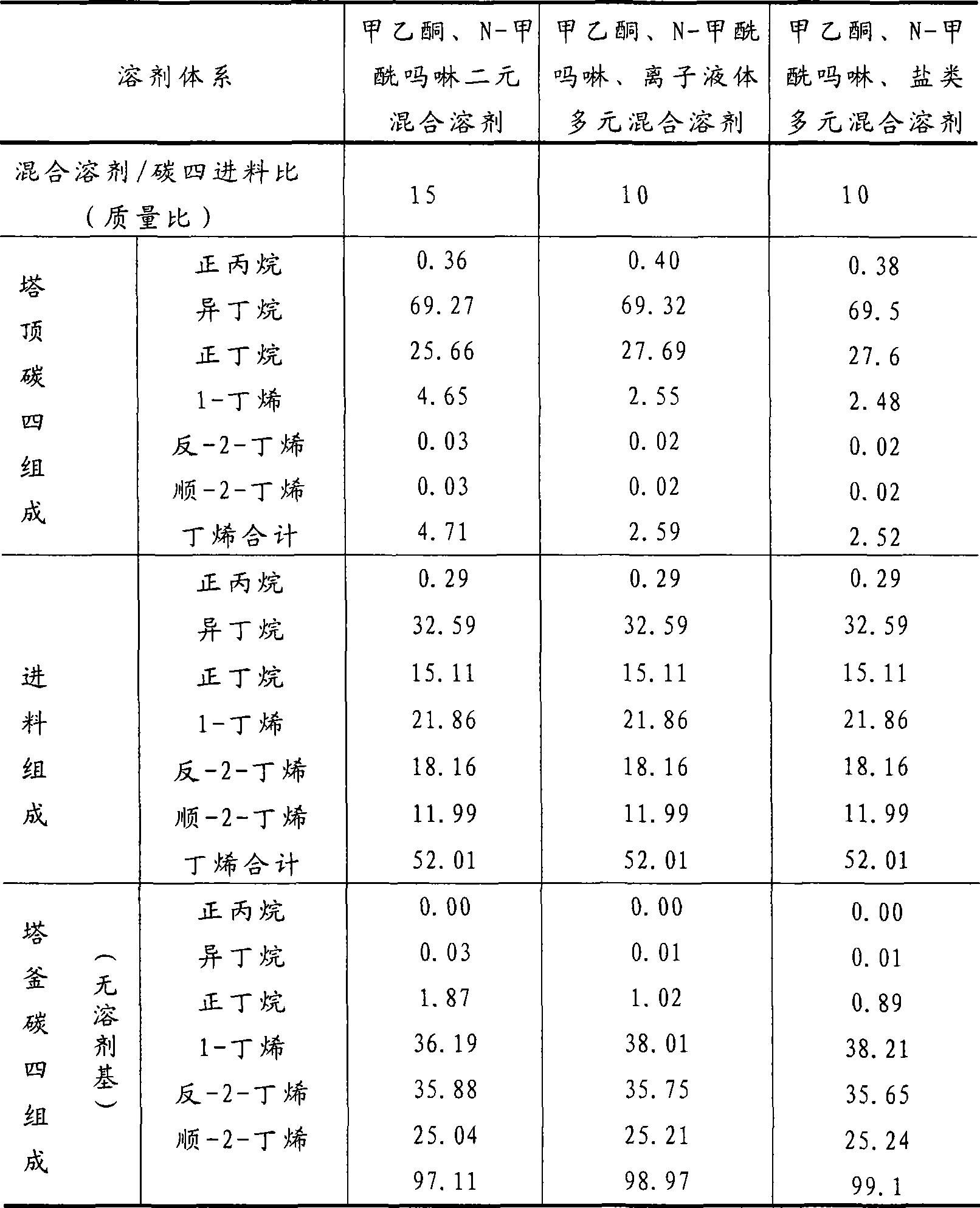

[0025] The C4 mixture to be treated is C4 after etherification, that is, the mixed C4 after producing MTBE, the solvent ionic liquid used is 1-methyl-3-octyl-imidazole hexafluorophosphate, and the salt is potassium thiocyanate , the ratio of ionic liquid, methyl ethyl ketone and nitrogen-formylmorpholine mixture is 1 / 2 / 2 (mass ratio), and the salt content is 5% (mass).

[0026] The extractive distillation tower (1 tower) used is a packing tower: the material is stainless steel, the tower diameter is 50 mm, and the packing is stainless steel wire mesh packing; the stripping tower (2 towers) is also a packing tower: stainless steel, the tower diameter is 50 mm, and the packing is θ ring packing ;

[0027] Both towers are thermally insulated;

[0028] Mixed carbon four is added from the middle of tower 1 at a temperature of 50°C;

[0029] Solvent / carbon four feed ratio: 6~15;

[0030] Operating pressure at the top of tower 1: 0.50MPa(G);

[0031] 2 tower top operating pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com