Full-silk-fibroin-based conductive gel sensor and preparation method thereof

A conductive gel and silk fibroin technology, applied in the field of wearable sensors, can solve the problems of high manufacturing cost of a single device, complex sensor preparation process, and difficulty in integrating sensors with multiple functions, and achieves good fit and conductivity. The effect of preserving solubility, high adhesion and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

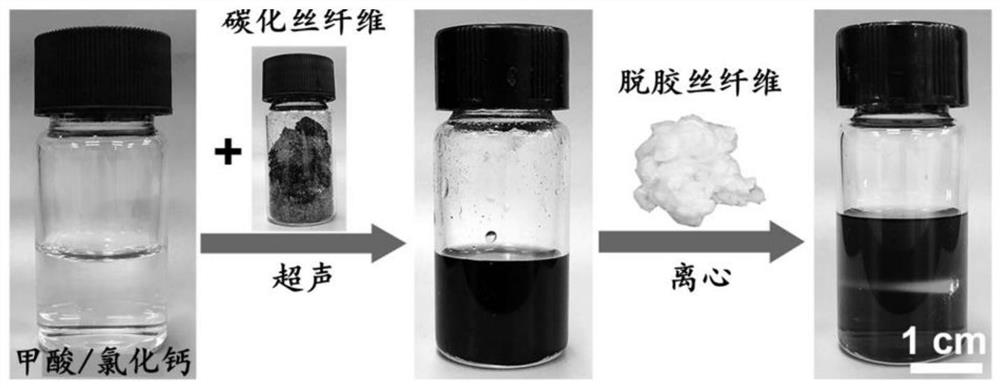

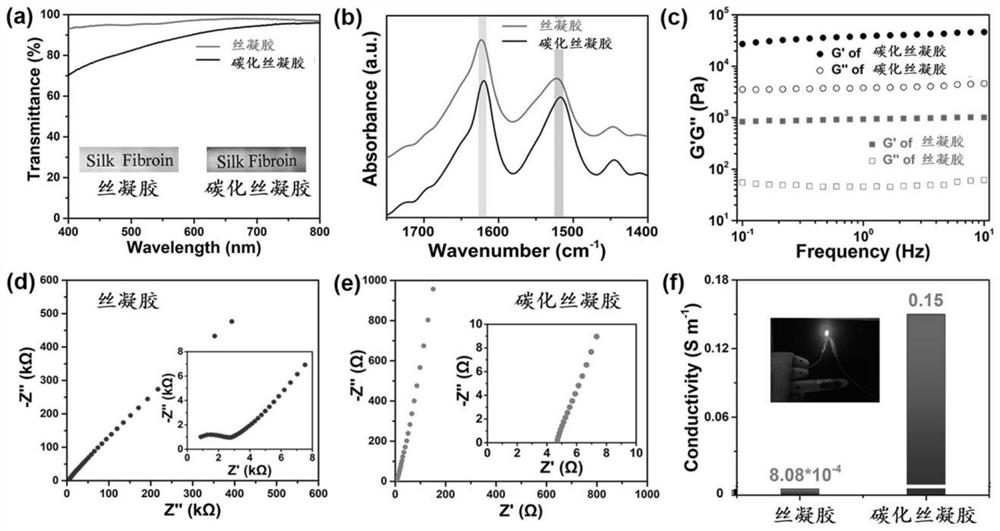

[0034] Add the degummed silk fiber with a mass fraction of 5% to the acid addition system, and the mass fraction of the carbonized silk fiber is 0.1 wt%. After stirring, ultrasonication, and centrifugation to remove insoluble impurities, it can be added to the silk fiber / carbonized silk fiber. A mixed acid solution of formic acid / calcium chloride. Immediately afterwards, slowly pour the above acid solution onto the bottom of the glass dish in the fume hood. After the formic acid evaporates, an acid gel will form at the bottom. Gel, also named carbonized silk gel. It should be noted that residual traces of formic acid may cause skin irritation and corrosion. For personal safety, the corresponding follow-up operations should be performed after the formic acid is completely volatilized. For example, when the carbonized silk gel is formed, it can be peeled off from the bottom of the glass dish (for details, refer to Figure 6 ), prepare carbonized silk gel, be embodiment 1.

Embodiment 2

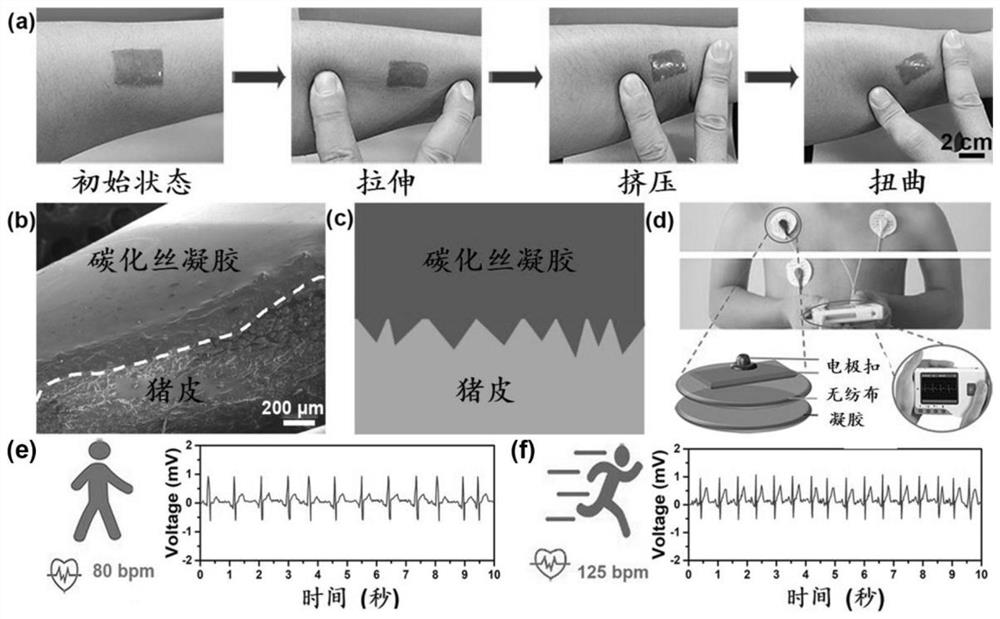

[0036] The degummed silk fiber with a mass fraction of 5% was added to the acid addition system, the mass fraction of carbonized silk fiber was 0.2 wt%, and the carbonized silk gel was prepared according to the preparation steps in Example 1, which was recorded as Example 2. Further, embodiment 2 can be improved as a conductive gel used as an ECG substitute electrode for acquiring electrocardiographic signals, so as to realize accurate measurement of electrocardiographic signals after human rest or exercise.

Embodiment 3

[0038] Degummed silk fibers with a mass fraction of 8% were added to the acid addition system, and the mass fraction of carbonized silk fibers was 0.5wt%. Carbonized silk gel was prepared according to the preparation steps in Example 1, which was recorded as Example 3. Furthermore, Example 3 can be prepared by VHB sandwich packaging to obtain a gel sensor for temperature sensing, which realizes a sensitive response to external temperature changes under non-contact conditions, and early warning of potential dangers around people.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com