A kind of production process of antibacterial non-woven fabric

A production process and technology of non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, biochemical fiber processing and other directions, can solve the problems of single function, restrict the use of non-woven fabrics, ineffective effects, etc., to extend antibacterial life, improve Passive antibacterial effect, effect of enhancing antibacterial and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

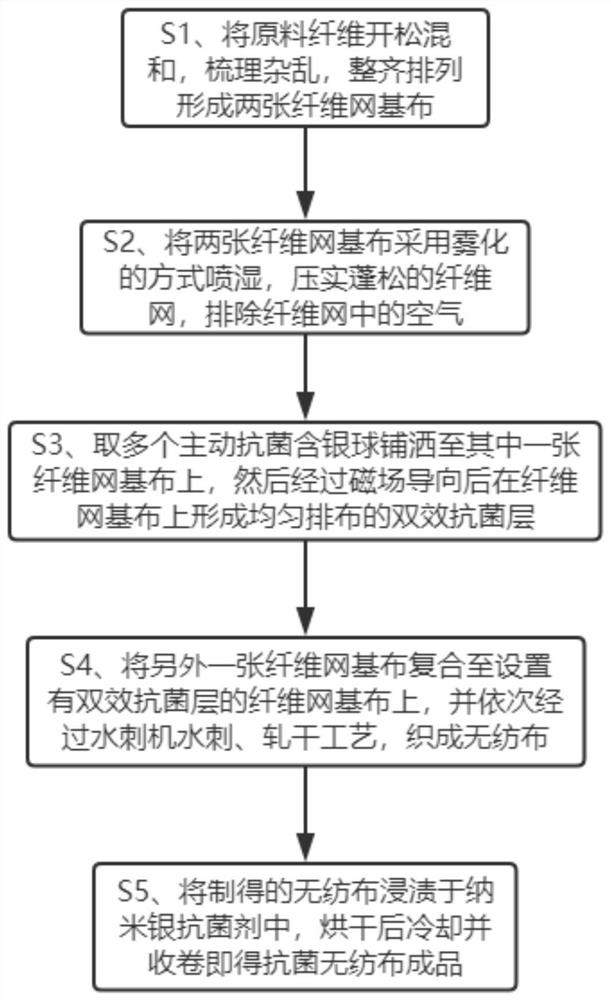

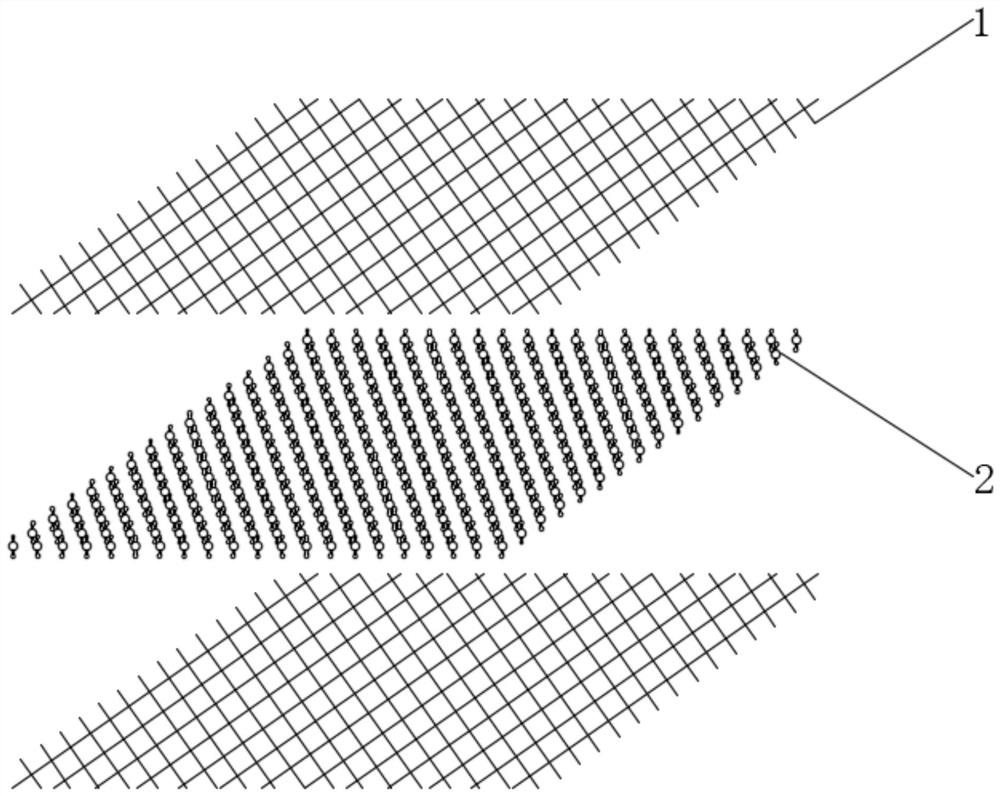

[0048] see Figure 1-2 , a production process of antibacterial non-woven fabric, comprising the following steps:

[0049] S1. Open and mix the raw fibers, comb them in a mess, and arrange them neatly to form two fiber mesh base cloths 1;

[0050] S2, spray the two fiber web base cloths 1 by atomization, compact the fluffy fiber web, and remove the air in the fiber web;

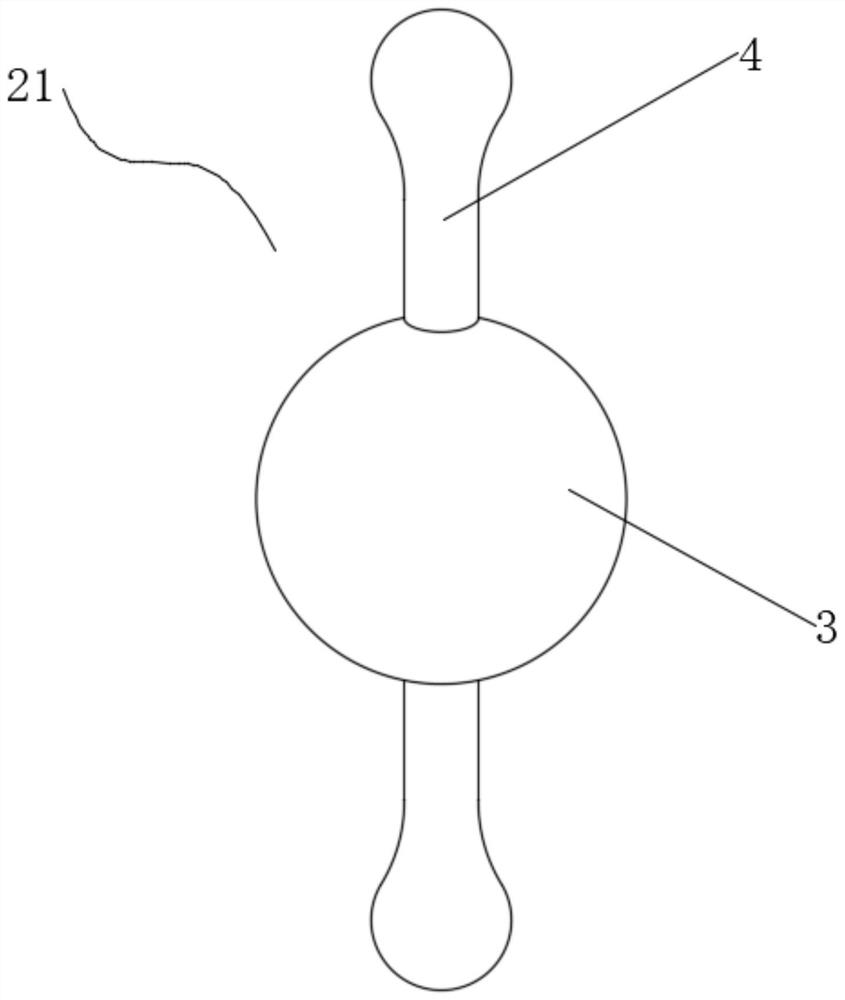

[0051] S3, take a plurality of active antibacterial silver-containing balls 21 and spread them on one of the fiber mesh base cloth 1, and then form a uniformly arranged double-effect antibacterial layer 2 on the fiber mesh base cloth 1 after being guided by a magnetic field;

[0052] S4, compound another fibrous mesh base cloth 1 to the fibrous mesh base cloth 1 provided with the double-effect antibacterial layer 2, and then go through the spunlace spunlace and rolling drying process in turn to form a non-woven fabric;

[0053] S5, immersing the prepared non-woven fabric in the nano-silver antibacterial agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com