A multi-stage airflow type industrial photocatalyst floor

An air flow, photocatalyst technology, applied in optics, optical components, separation methods, etc., can solve problems such as difficult air mobility, and achieve the effect of improving fluidity, increasing fluidity, and improving purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

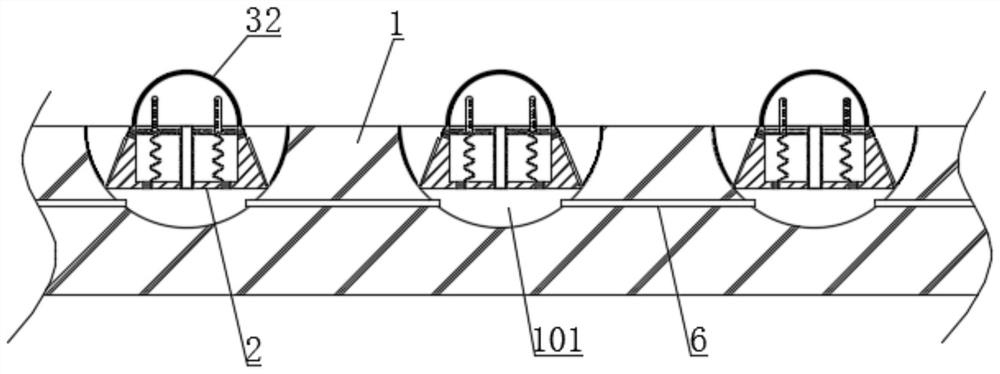

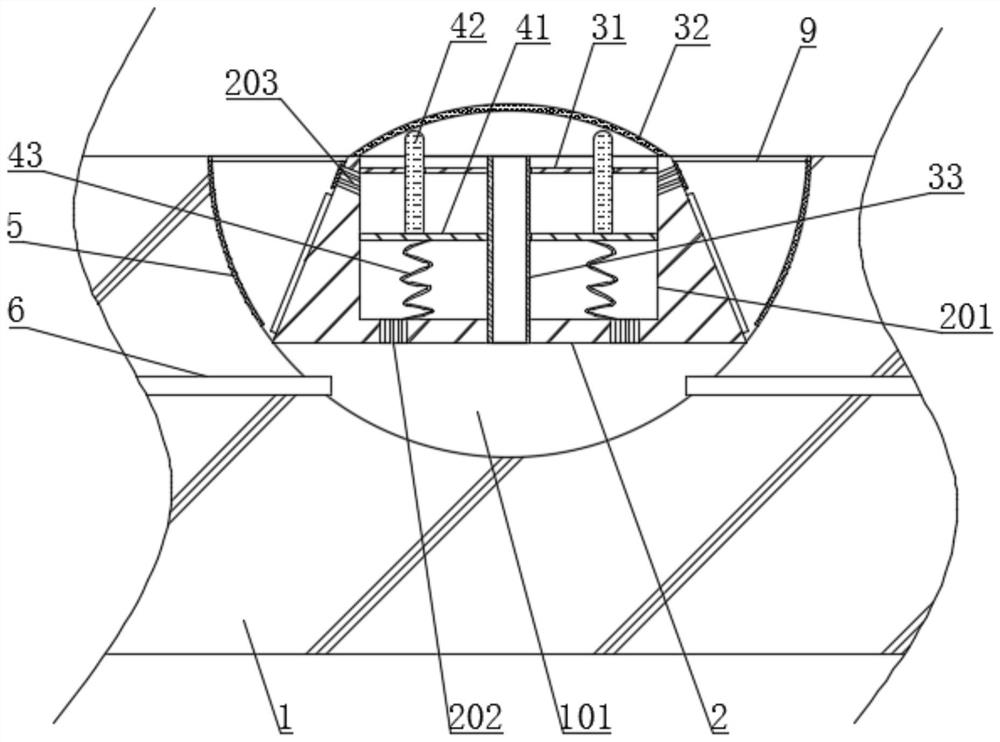

[0041] see figure 1 , a multi-stage airflow type industrial photocatalyst floor, including a floor 1, the upper end of the floor 1 is provided with a plurality of evenly distributed inner grooves 101, and the inside of the inner groove 101 is provided with a multi-stage air flow table, please refer to figure 2 , the inwall of inner groove 101 is coated with photocatalyst layer 5, and photocatalyst layer 5 can select titanium dioxide material for use, and photocatalyst layer 5 is positioned at the outside of multistage air flow table, and multistage air flow table includes the built-in platform 2 that is fixedly connected with inner groove 101 inwall, built-in platform The upper end of 2 is provided with a groove 201, and the interior of the groove 201 is provided with an inner jet mechanism. The inner jet mechanism includes a fixed plate 31 and an air guide tube 33 located inside the groove 201. The air guide tube 33 runs through the fixed plate 31 and connects with the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com