Seam coating device for wooden floor assembly based on whole wood home furnishing

A wood and floor technology, which is applied in cleaning floors, household utensils, applications, etc., can solve the problems of not being able to realize raw materials in linkage, and not being able to realize pre-cleaning of filling positions at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

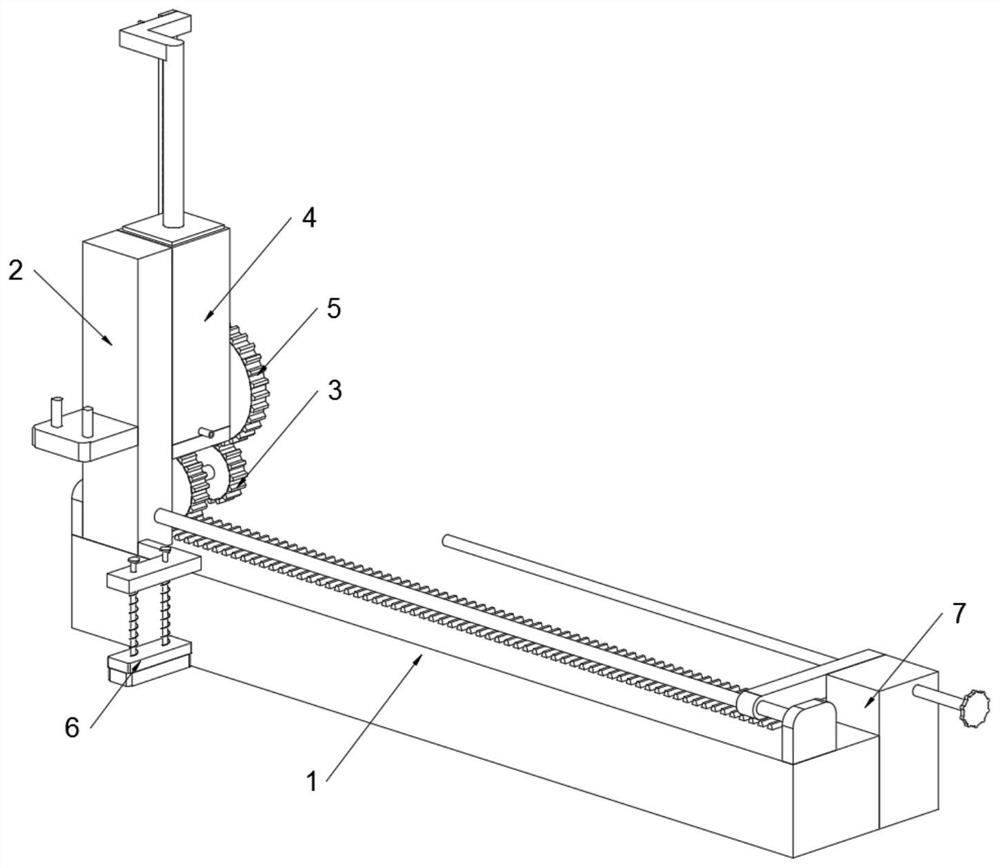

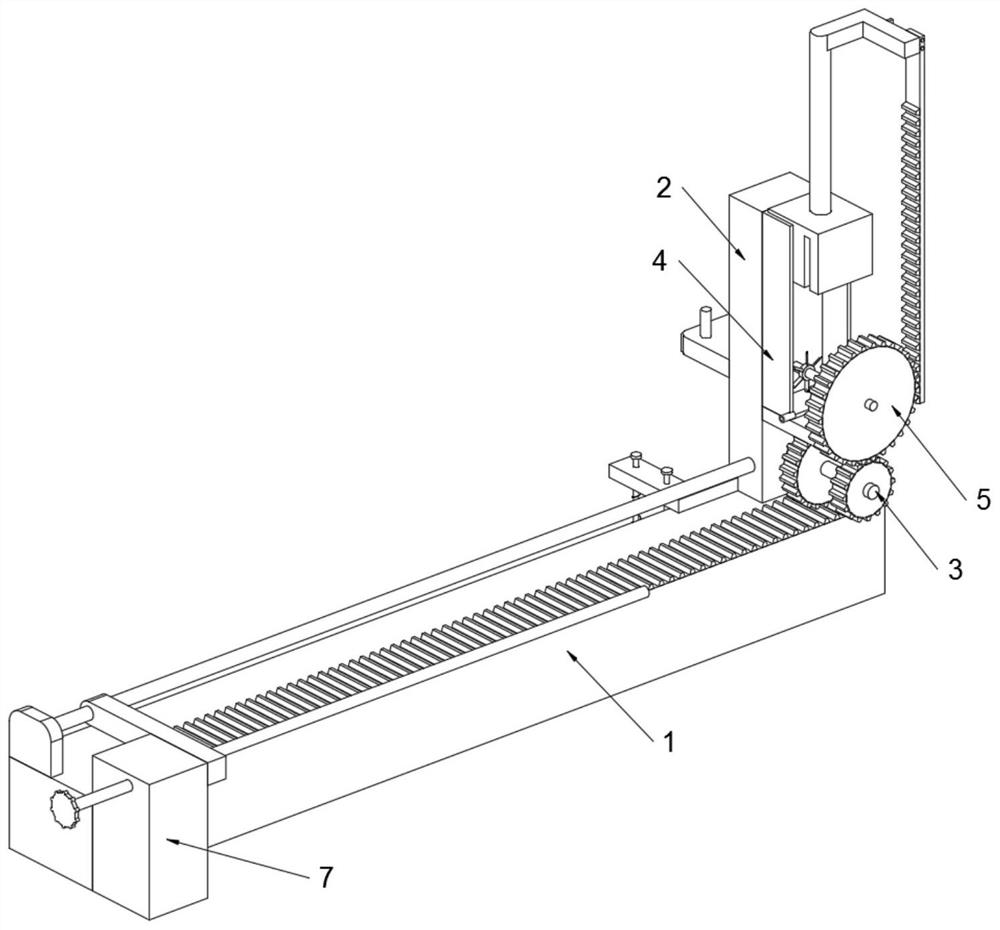

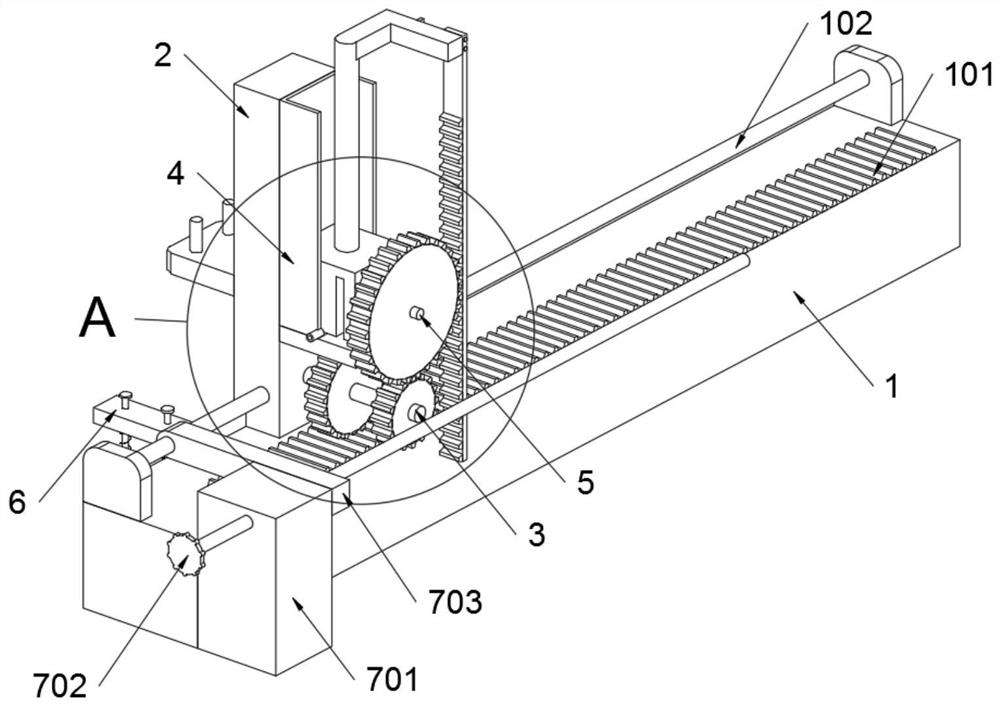

[0035] as attached figure 1 To attach Figure 8 Shown:

[0036] The present invention provides a wooden floor assembly seam coating device based on whole wood furniture, which includes a base 1 and an extrusion head 402; a main body seat 2 is slidably connected to the base 1, and a transmission structure 3 is installed on the main body seat 2; Extrusion structure 4 is installed on 2, and mixing structure 5 is installed on extrusion structure 4; Figure 5 with Image 6, the extrusion head 402 includes a rectangular groove 40201, two rectangular grooves 40201 are opened on the bottom surface of the extrusion head 402, and the size and position of the rectangular groove 40201 match the size and position of the blade 502, and when the bottom surface of the extrusion head 402 When in contact with the bottom end surface of the inner wall of the storage barrel 401, the vane 502 and the rectangular groove 40201 are in a contained state, thereby reducing the residue of raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com