Etching device for positive concave etching of super-thick copper wire of ceramic-based circuit board

An etching device and circuit board technology, which is applied in the field of circuit board processing, can solve the problems of affecting efficiency, manually shaking the circuit board, cumbersome operation, etc., and achieve the effect of reducing the dead angle of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

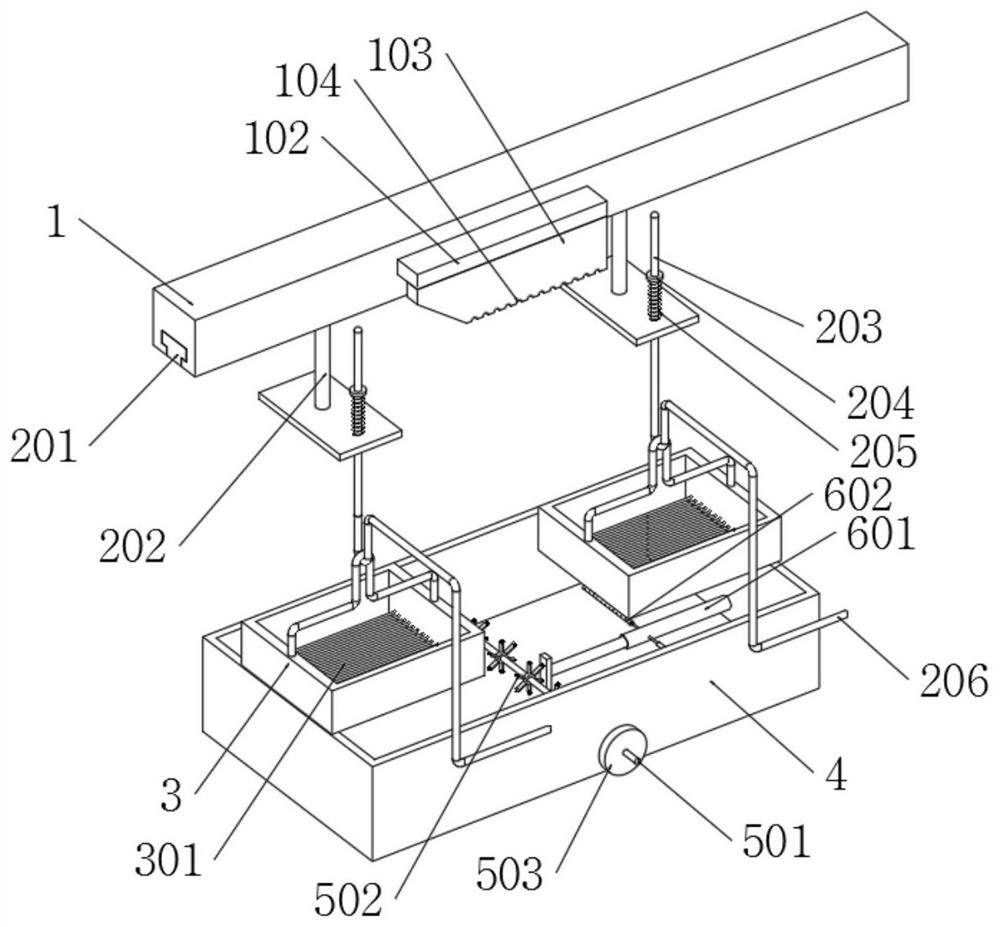

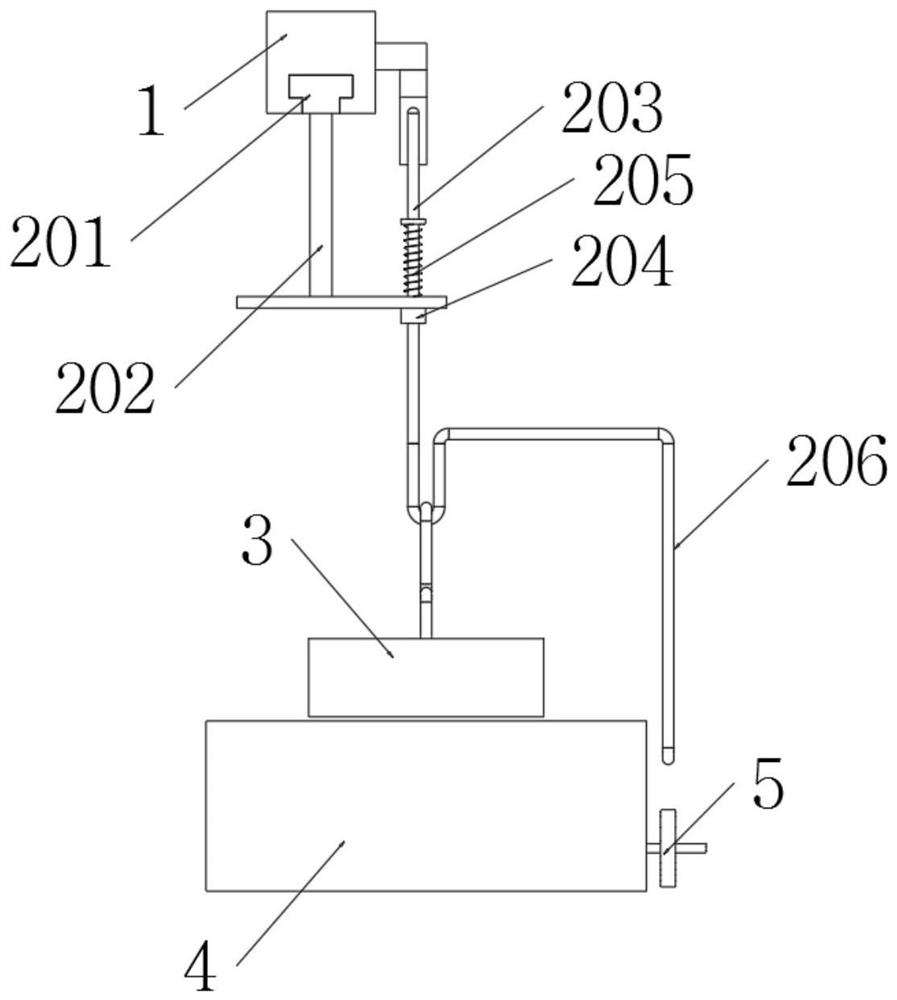

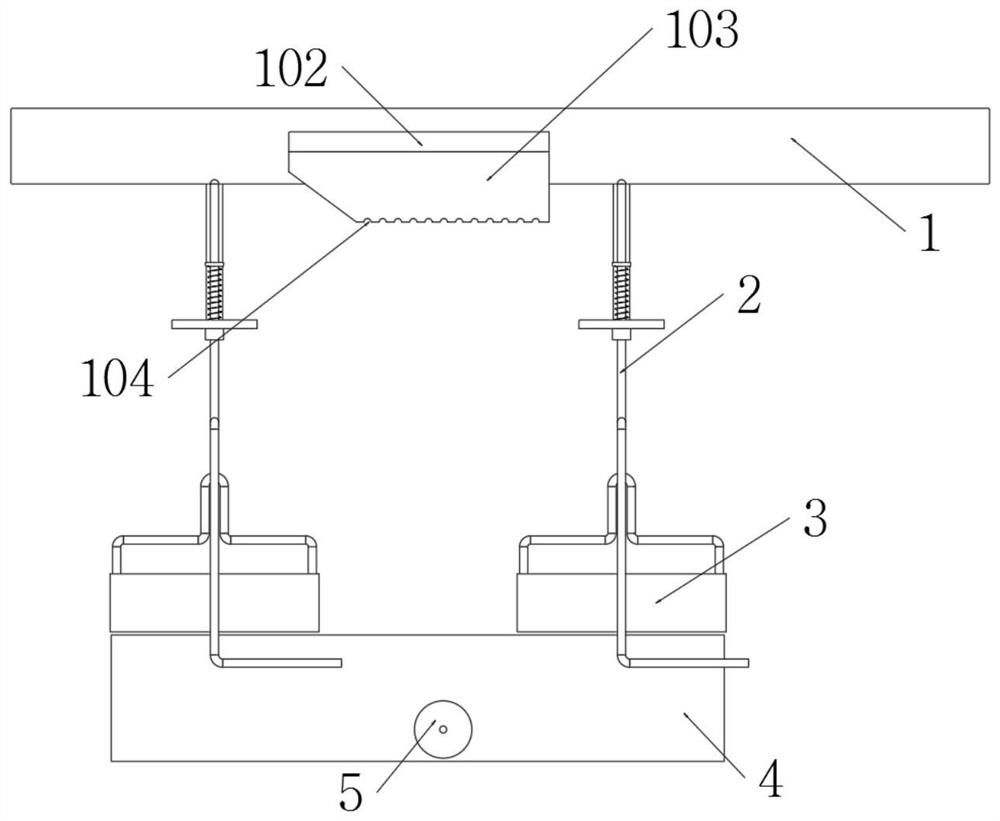

[0046] The invention provides an etching device for positive concave etching of ultra-thick copper wires of a ceramic base circuit board, comprising: an assembly line 1 and a suspension part 2;

[0047] The assembly line 1 is fixed on the mounting frame by bolts;

[0048] The suspension part 2 is composed of a sliding block 201, a connecting seat 202, a suspension rod 203, a retaining ring 204, an elastic member 205 and an auxiliary rod 206, and the sliding block 201 is slidably connected in the assembly line 1;

[0049] The etching box 4 is placed on the ground, and the etching box 4 contains etching liquid.

[0050] Furthermore, according to embodiments of the present invention, such as figure 1 and Figure 7As shown in the figure, the bottom end face of the assembly line 1 is provided with cleaning grooves 101 in a linear array, and the cleaning grooves 101 opened in the linear array form together the cleaning structure of the residues in the assembly line 1, so when the ...

Embodiment 2

[0063] An etching device for positive concave etching of ultra-thick copper wires of a ceramic-based circuit board, comprising: an auxiliary part 5;

[0064] Furthermore, according to embodiments of the present invention, such as figure 1 As shown, impellers 502 are installed on the rotating shaft 501 in a linear array, and the rotating shaft 501 and the impellers 502 installed in a linear array form a mixing structure of the etching liquid in the etching tank 4. When the rotating shaft 501 rotates, the impeller 502 can realize etching Auxiliary mixing of liquids.

[0065] Furthermore, according to embodiments of the present invention, such as figure 1 As shown, a friction wheel 503 is installed on the rotating shaft 501;

[0066] The auxiliary rod 206 is welded on the suspension rod 203, and when the head end of the suspension rod 203 is in contact with the bottom end surface of the force receiving block 103, the auxiliary rod 206 contacts the outer wall of the friction whe...

Embodiment 3

[0070] An etching device for positive concave etching of ultra-thick copper wires of a ceramic-based circuit board, comprising: a mixing part 6; in box 4.

[0071] Furthermore, according to embodiments of the present invention, such as Figure 9 and Figure 10 As shown, the elastic piston bottle 601 is connected with a nozzle 602, and the nozzle 602 is provided with nozzle holes 603 in an annular array;

[0072] The head end of the elastic piston bottle 601 is in contact with the impeller 502, and when the impeller 502 rotates, the elastic piston bottle 601 is in a continuous expansion and contraction shape, then the gas in the elastic piston bottle 601 will be ejected from the nozzle hole 603 at this time. The auxiliary mixing of the etching liquid in the etching tank 4 is provided, that is to say, the etching effect can be improved under the condition that the etching liquid is mixed in the etching tank 4 .

[0073] The specific usage mode and function of this embodiment:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com