Fire distributor with two variable fire hole airway characteristics

A fire device and fire distributor technology, which is applied in the field of burner fire distributors, can solve the problem of small proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

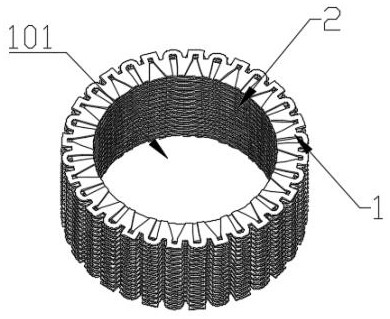

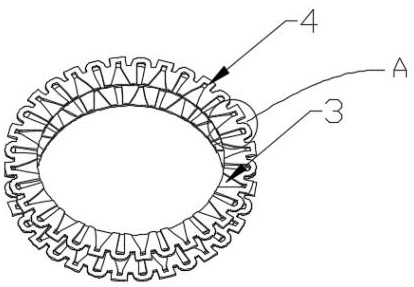

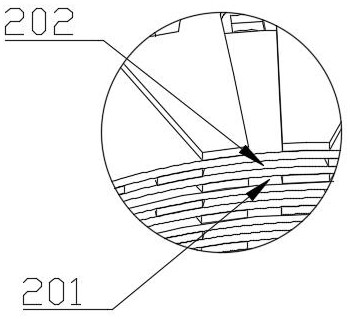

[0023]Embodiment 1: The first annular disc 3 and the second annular disc 4 form a firearm body, and the first air outlet 201 and the second air outlet 202 are arranged on the inner wall 1 of the fire distributor , the first air outlets 201 are arranged in a straight line in the vertical direction, and the second air outlets 202 are arranged in a straight line in the vertical direction. The width of the groove root 4011 gradually decreases, and the pressure of the mixed gas flow out of the first gas outlet 201 on the inner wall of the fire distributor 2 is high and the flow rate is fast; the width of the inner ring of the second comb tooth groove top 4022 gradually increases toward the second comb tooth groove root 4021 Large, and then the mixed gas flow out from the second gas outlet 202 has low pressure and slow flow rate, the mixed gas with low pressure and slow flow rate burns near the inner wall 2 of the fire distributor, and the mixed gas with high pressure and fast flow i...

Embodiment 2

[0024] Embodiment 2: The first annular disc 3 and the second annular disc 4 form a firearm body 1, and the first air outlet 201 and the second air outlet 202 are arranged on the inner wall 2 of the fire distributor Above, the first gas outlets 201 and the second gas outlets 202 are arranged vertically alternately and in a straight line. Compared with Example 1, in this arrangement, the flame is a mountain-shaped flame with an upward compact shape.

[0025] As another preferred embodiment of the present invention, the second annular disc 4 is provided with outer ring teeth 408, and the top of the outer ring teeth 408 is provided with outer ring tooth cusps 407. The outer ring tooth groove 406 and the outer ring tooth groove root 405 are arranged between the adjacent outer ring teeth 408. The shapes of the adjacent outer ring teeth 408 are different, which is convenient for distinguishing the first annular disk 3 and the second annular disk. Sheet 4 arrangement.

[0026] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com