Method and device for measuring water content in hydrogen fluoride by utilizing Fourier transform infrared spectroscopy

A Fourier transform and infrared spectroscopy technology, applied in the field of hydrogen fluoride detection, can solve problems such as data errors, and achieve the effect of simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

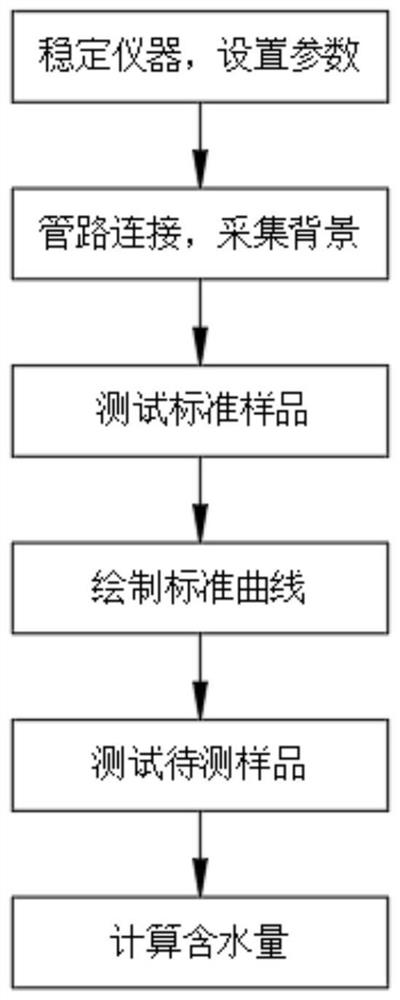

[0052] Step 1, turn on the Fourier transform infrared spectrometer, add an appropriate amount of liquid nitrogen to the instrument, the instrument is stable for more than half an hour, and set the following parameters: acquisition time 32s, scan times 32 times, resolution 4cm -1 , analysis range 400-4400cm -1 . Connect 99.999% high-purity helium gas cylinders, hydrogen fluoride standard gas cylinders containing water with different concentrations, and hydrogen fluoride sample cylinders to be tested to the Fourier transform infrared spectrometer. Open the 99.999% helium cylinder, and perform vacuum-helium replacement on the entire analysis pipeline. The purpose is to remove impurities in the pipeline, replace 5 times, vacuumize to a pressure of -0.1Mpa, carry out background collection, and Save the background spectrum.

[0053] Step 2, carry out high-purity helium-vacuum replacement to the pipeline between the Fourier transform infrared spectrometer and the hydrogen fluoride ...

Embodiment 2

[0059] The steps used are the same as in Example 1. The difference is that in step 2, the characteristic peak of water is selected as: 1488cm -1 . After detection and calculation, the analysis results are shown in Table 1.

Embodiment 3

[0061] The steps used are the same as in Example 1. The difference is that in step 2, the characteristic peak of water is selected as: 1868cm -1 . After detection and calculation, the analysis results are shown in Table 1.

[0062] The content of water in table 1 hydrogen fluoride

[0063]

[0064] It can be seen from Table 1 that these characteristic peaks can accurately determine the water content in hydrogen fluoride.

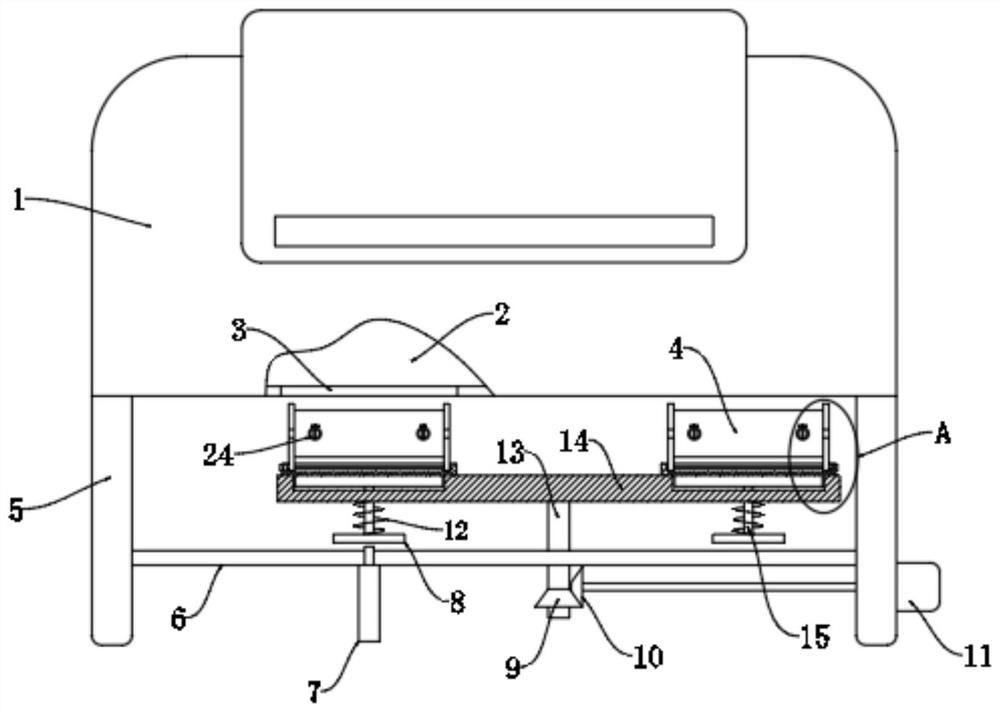

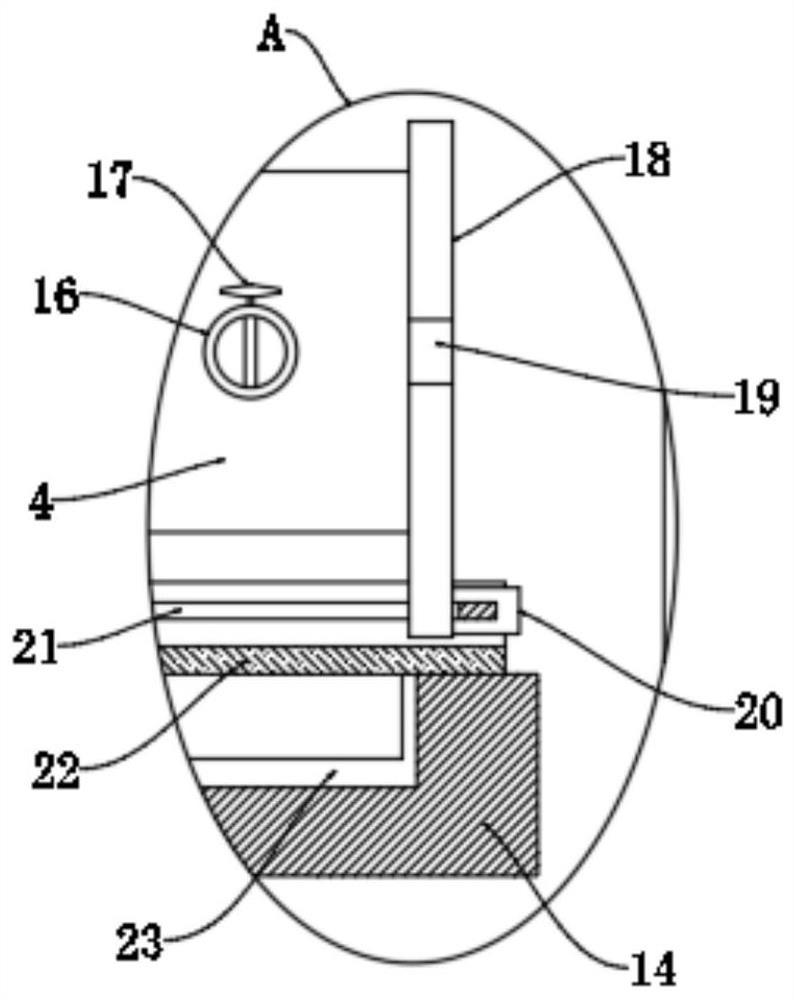

[0065] In order to realize simultaneous sampling of multiple standard samples and improve detection efficiency, the present invention also provides a Fourier transform infrared spectrum detection device, such as Figure 4 As shown, it includes a Fourier transform infrared spectrometer body 1, a detection chamber 2 is arranged in the Fourier transform infrared spectrometer body 1, and two support plates 5 are fixed on the bottom of the Fourier transform infrared spectrometer body 1, and a fixing plate is fixed between the two support plates 5. Plate 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com