Stacker safety evaluation method and system based on parametric design

A technology of parametric design and safety evaluation, applied in the field of stacker crane design, can solve problems such as low efficiency, large proportion of time occupied by repetitive labor, and insufficient time for development and innovation, and achieve the effect of improving work efficiency and simplifying workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for evaluating the safety of a stacker based on parametric design;

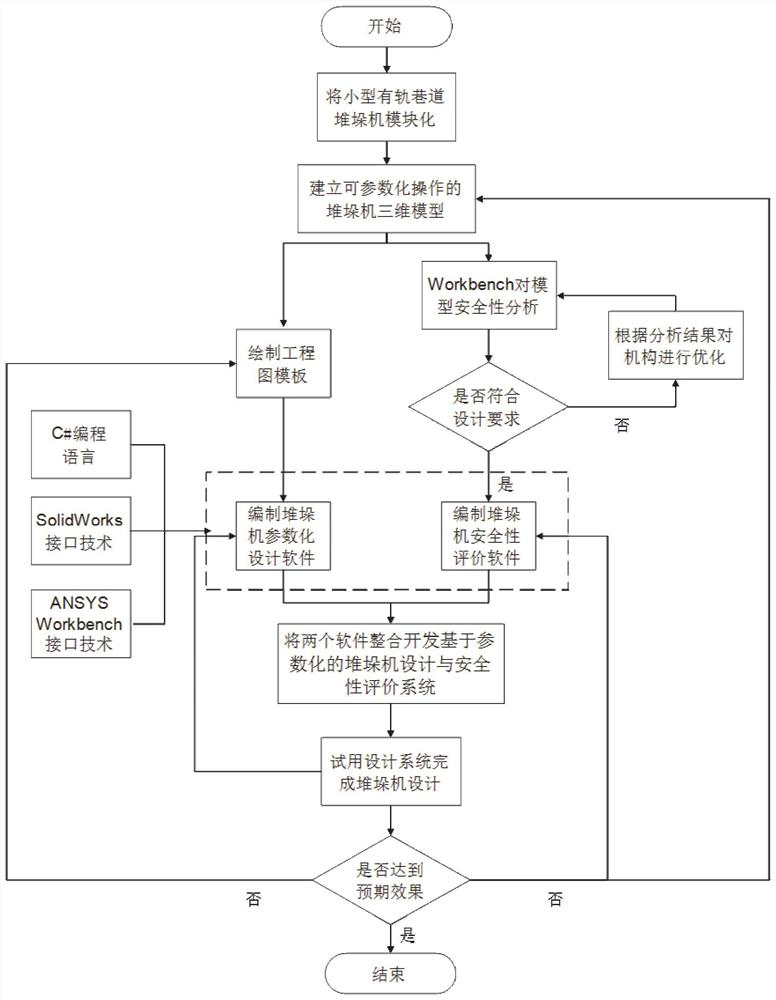

[0031] Such as figure 1 and figure 2 As shown, the safety evaluation method of stacker crane based on parametric design includes:

[0032] S101: Obtain the basic parameters of the stacker; establish a three-dimensional model of the stacker according to the basic parameters of the stacker; the relationship between S102 and S103 is concurrent;

[0033] S102: Generate a two-dimensional engineering drawing of each component of the stacker according to the relationship between the three-dimensional model and the two-dimensional engineering drawing of the component;

[0034] S103: Perform finite element simulation analysis on the three-dimensional model of the stacker, make an analysis report according to the simulation result, and obtain a safety evaluation result of the stacker.

[0035] As one or more embodiments, the acquisition of the basic parameters of the stacker...

Embodiment 2

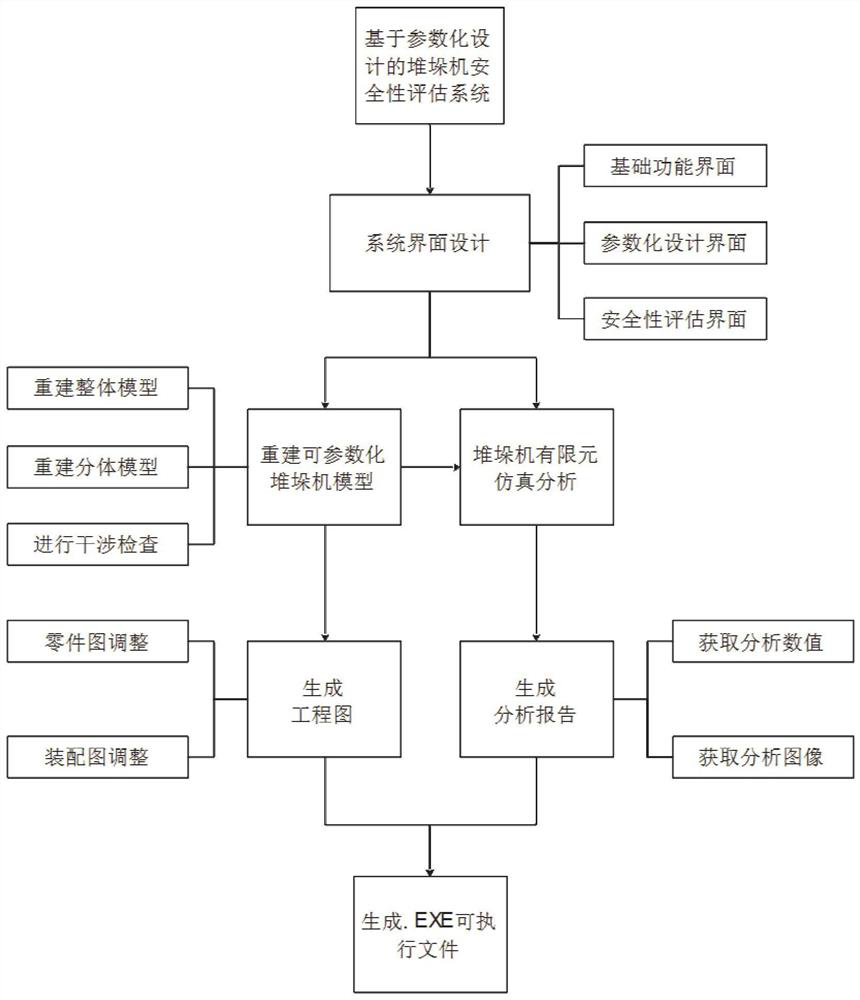

[0077] This embodiment provides a safety evaluation system for stackers based on parametric design;

[0078] A safety evaluation system for stacker cranes based on parametric design, including:

[0079] An acquisition module configured to: acquire basic parameters of the stacker; establish a three-dimensional model of the stacker according to the basic parameters of the stacker;

[0080] The generation module is configured to: generate a two-dimensional engineering drawing of each component of the stacker according to the association relationship between the three-dimensional model and the two-dimensional engineering drawing of the component;

[0081] The output module is configured to perform finite element simulation analysis on the three-dimensional model of the stacker, make an analysis report according to the simulation result, and obtain the safety evaluation result of the stacker.

[0082] It should be noted here that the acquisition module, generation module and outpu...

Embodiment 3

[0086] This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the one or more computer programs are programmed Stored in the memory, when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in Embodiment 1 above.

[0087] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com