High-temperature circuit breaker for electric automobile power detection

A technology for electric power detection and electric vehicles, which is applied to the cleaning method of tools, circuits, electric switches, etc., can solve the problems of easily causing bolt slippage, inconvenient disassembly, affecting the efficiency of heat dissipation, etc., and achieve the effect of increasing heat dissipation. , Easy to replace and repair, easy to connect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

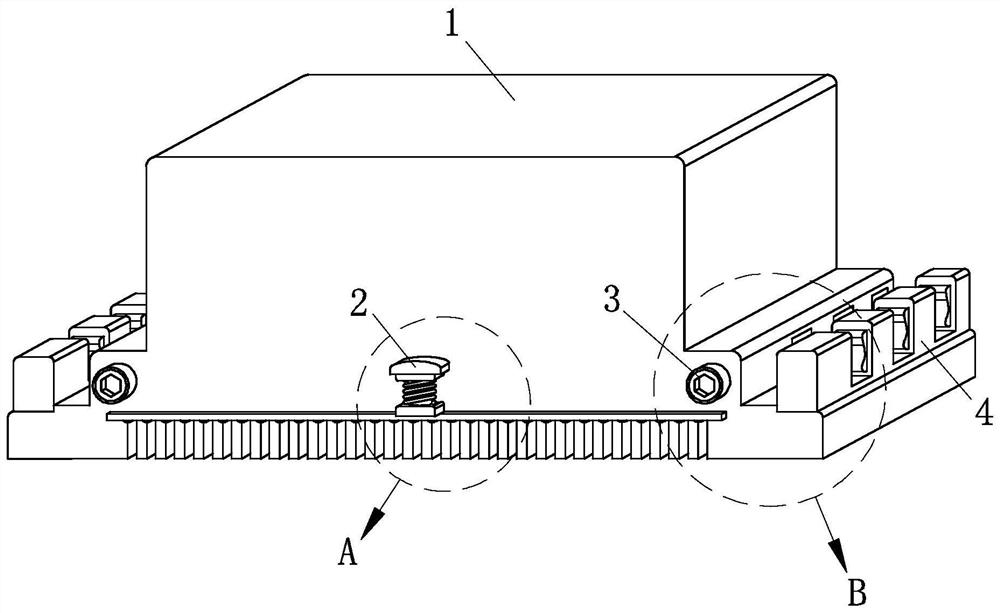

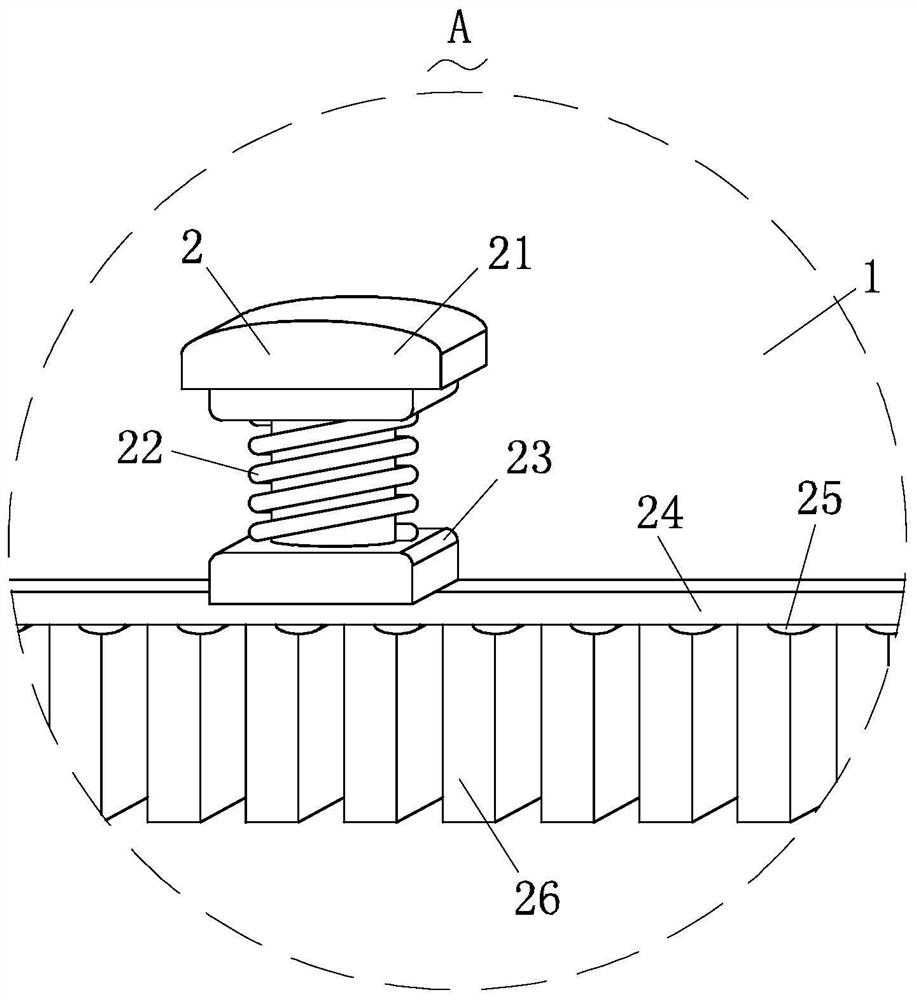

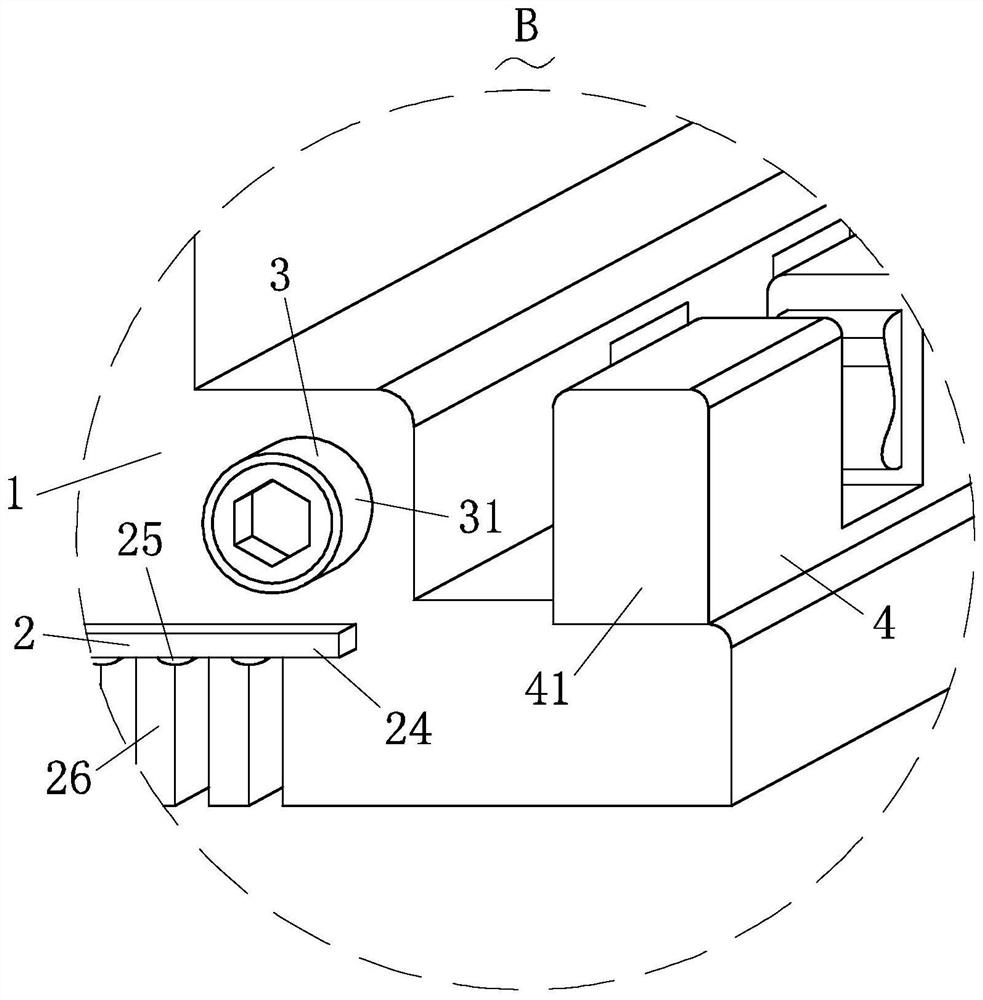

[0025] Such as Figure 1-Figure 7 As shown, a high-temperature circuit breaker for electric vehicle power detection according to the present invention includes a circuit breaker body 1, a dust removal mechanism 2, an extrusion mechanism 3, a positioning mechanism 4, an interference mechanism 5, and a fixing mechanism 6, which are used to control the circuit The squeezing mechanism 3 for fixed connection of external wires is installed on the inner sides of both ends of the circuit breaker body 1 for overheating protection; the bottom ends of the circuit breaker body 1 are respectively installed with two symmetrically distributed The positioning mechanism 4 for positioning and clamping the wire; the bottom of the breaker body 1 is installed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com