Soft package lithium battery pack assembly structure

A technology of lithium battery pack and assembly structure, which is applied in the direction of lithium battery, battery pack components, batteries, etc., can solve the problems of inability to dissipate heat in time, damage to the battery pack structure, and impact on battery life, so as to solve the problem of serious battery aging and reduce battery life. Puncture risk, reduced use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

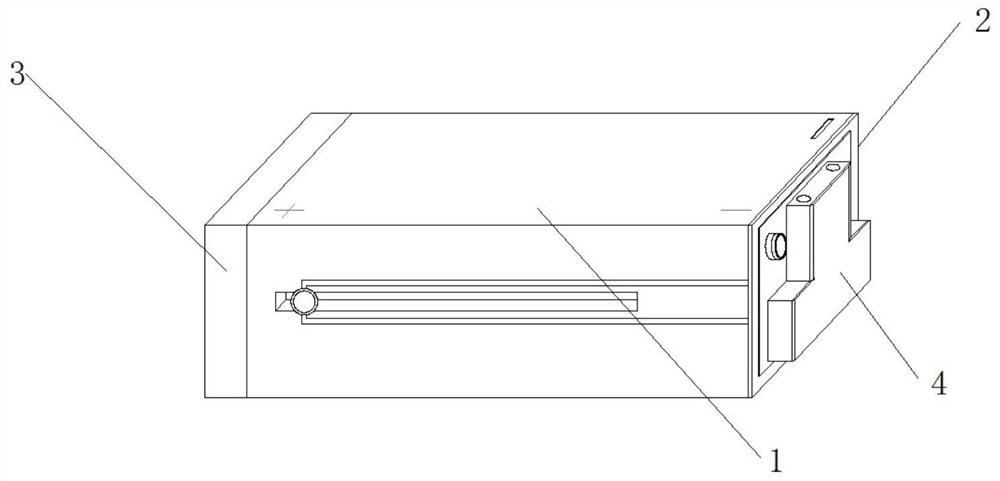

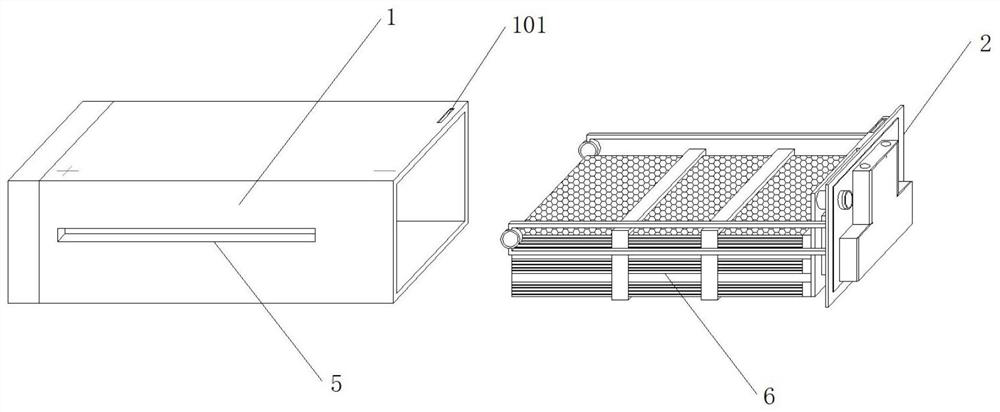

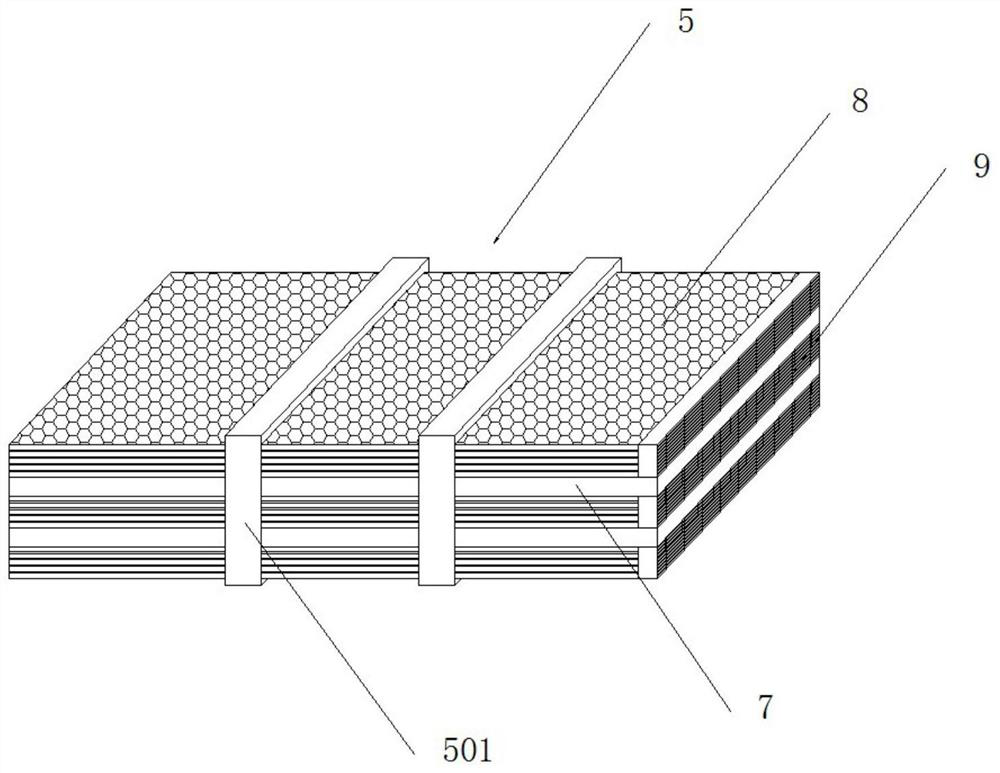

[0020] see Figure 1-4 As shown, an assembly structure of a soft pack lithium battery pack includes a battery box 1, a door 2, a positive connection plate 3 and a negative connection plate 4 located at both ends of the battery box 1, and a lithium battery pack 6, and the door 2 is arranged on the battery box 1, the negative connection plate 4 is set on the door 2, the lithium battery pack 6 includes several soft pack batteries 7 connected in series and a honeycomb heat exchange plate 8, and the two are aligned and pressed through the aluminum plate frame 501, A heat exchange frame 9 is installed at the end of the heat exchange plate 8, and a heat conduction plate 10 is installed on the inside of the door 2. The lithium battery pack 6 is installed on the inside of the door 2 through the cooperation of the heat exchange frame 9 and the heat conduction plate 10, and passes through the door. 2 Fill it into the battery box 1; the door 2 is provided with several connecting frames 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap