Laser Beam Product Parameter Adjustments

A beam parameter product, laser beam technology, applied in lasers, laser parts, optics, etc., can solve the problems of beam parameter product damage, loss of laser use qualifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

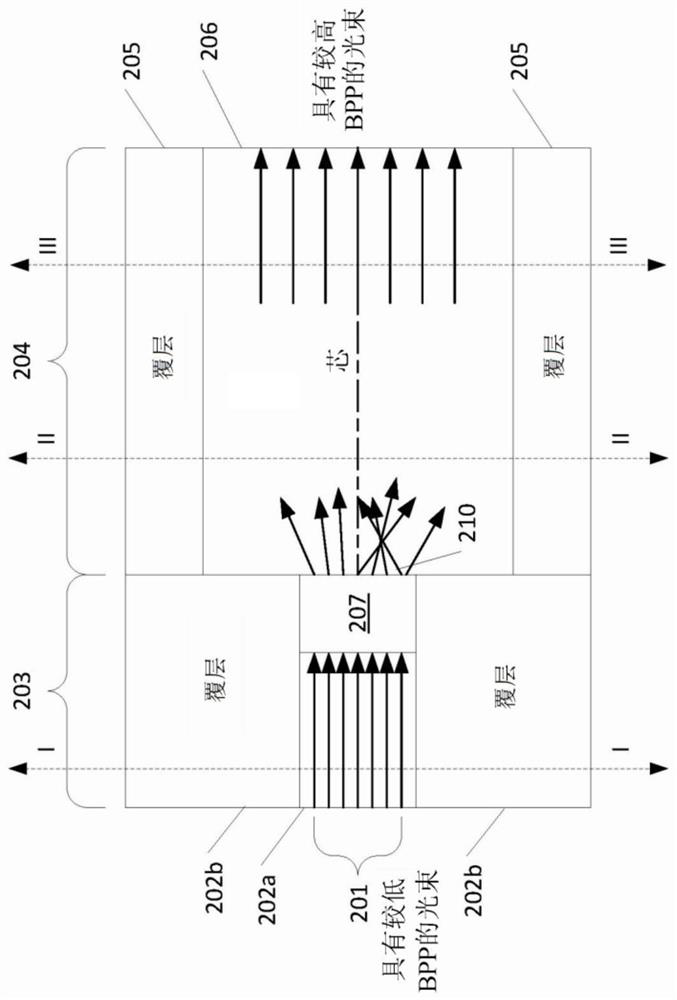

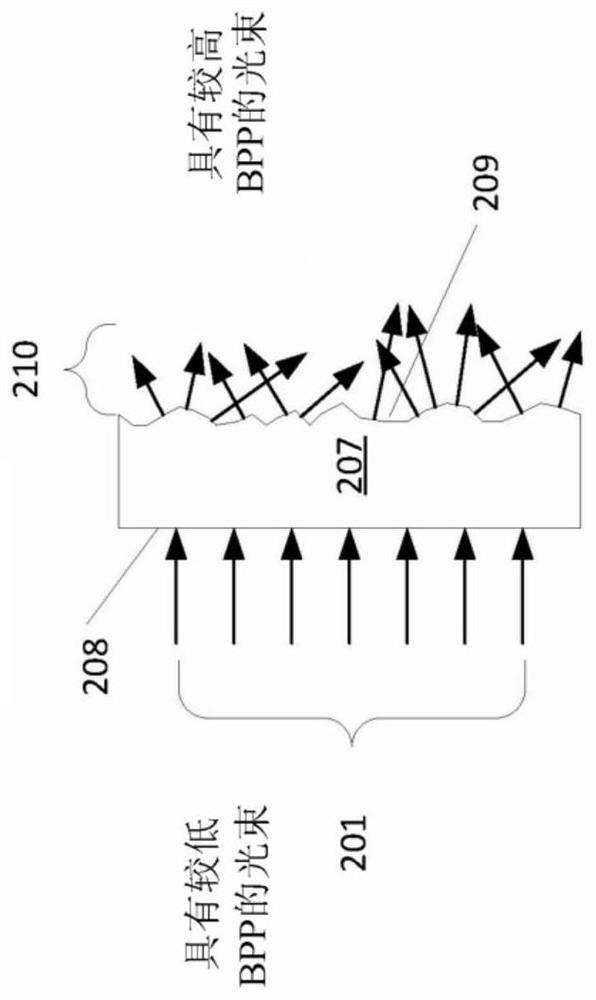

[0021] The accompanying drawings, which constitute a part hereof, illustrate examples of the disclosure. It should be understood that the examples shown in the figures and / or discussed herein are non-exclusive and that there are other examples of how the present disclosure may be practiced.

[0022] Also, the phraseology and terminology used herein are for the purpose of description and should not be regarded as limiting. Instead, phrases and terms used herein are to be given their broadest interpretations and meanings.

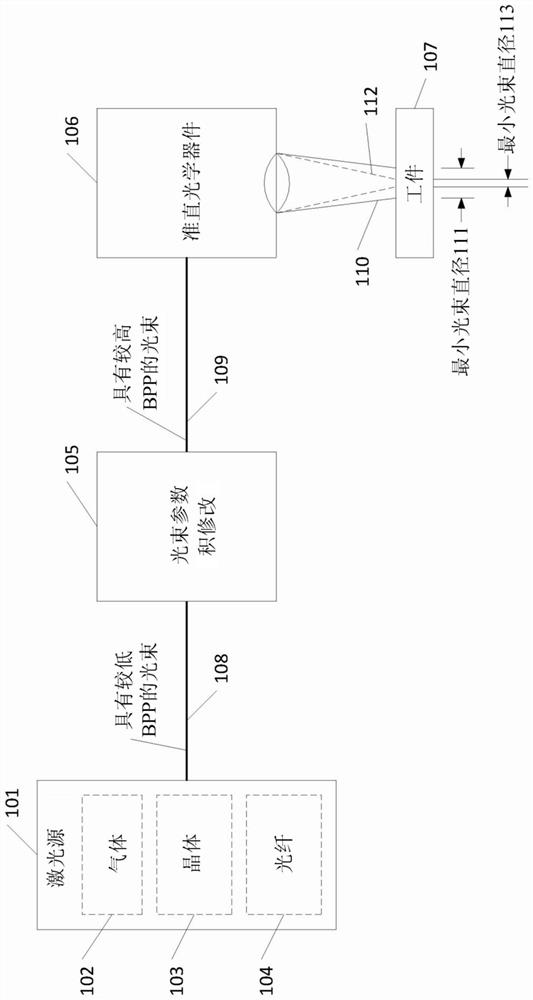

[0023] Industrial laser systems are used for a variety of tasks from cutting to welding to heat-related coating, including cladding and hardening. Some industrial laser systems use multimode fiber, while others use singlemode fiber. Different characteristics of laser beams make some beams suitable for one task and not another. For example, cutting tasks require lasers with low beam parameter products, while cladding and hardening tasks require lasers with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com