A device for quickly stripping the insulation layer of power cables

A technology for power cables and insulating layers is applied in the field of equipment for rapidly stripping the insulating layers of power cables, and can solve the problems of difficulty in extracting the outer layer of the insulating layer, potential safety hazards, and the blade easily scratching the wire core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

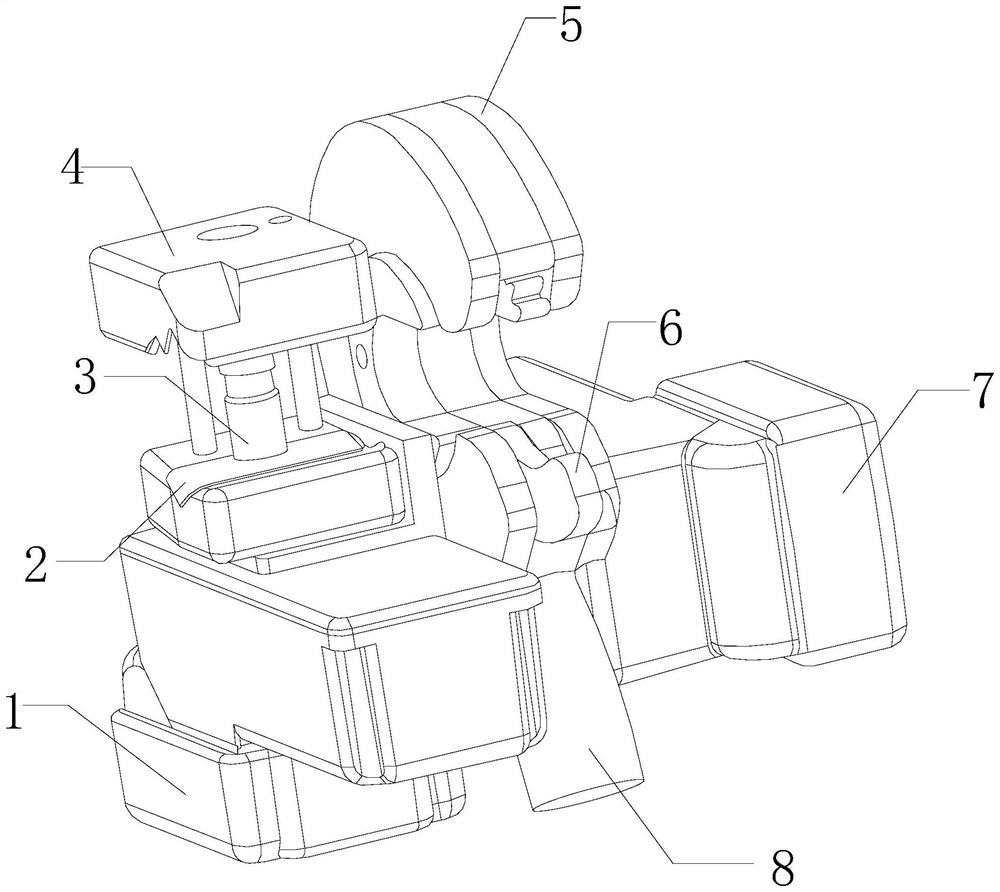

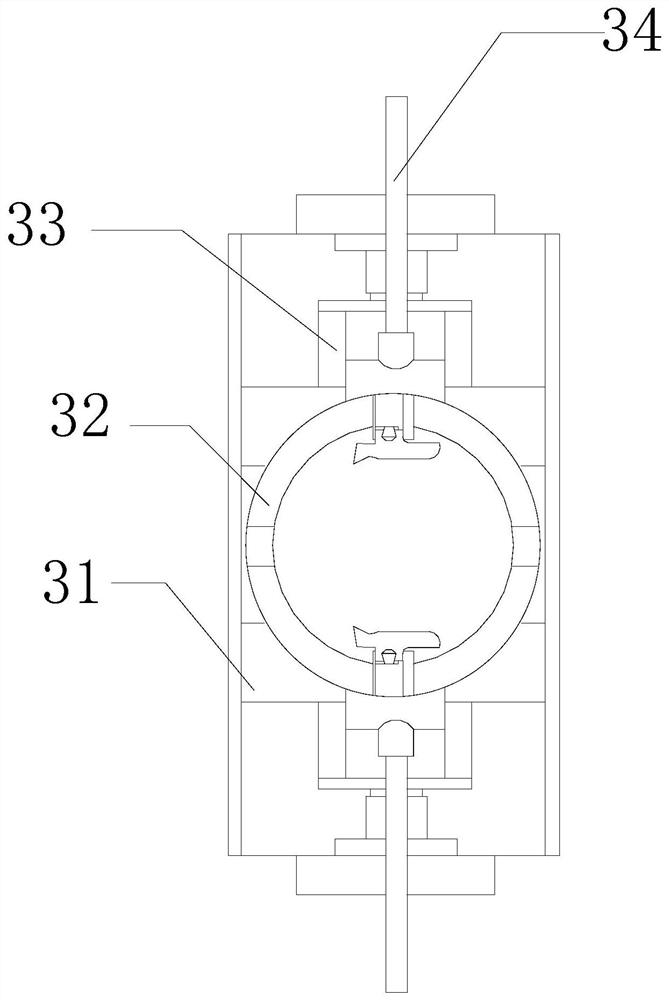

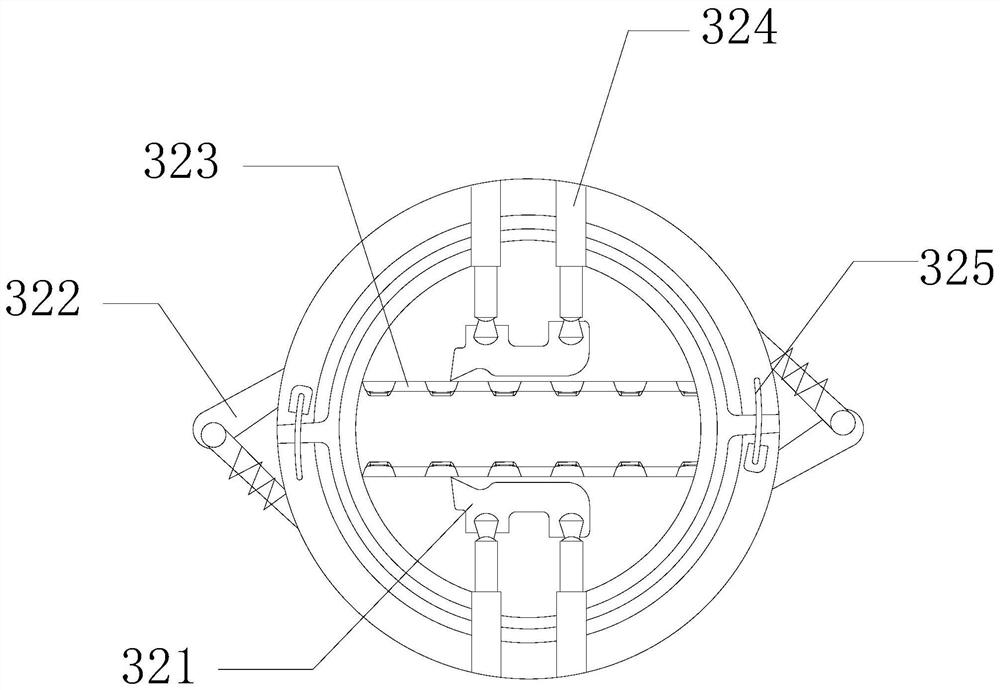

[0034] see figure 1 , the present invention provides a technical solution: a device for quickly stripping the insulation layer of a power cable, the structure of which includes a main body 1, an extraction table 2, a pulling device 3, a clamping member 4, a processing tank 5, and a cutting device 6 , a support block 7, a joystick 8, the upper end of the main body 1 is provided with a pull-out table 2, the pull-out table 2 is vertically fitted on the main body 1, the upper end of the pull-out table 2 is connected with a pulling device 3, the The pulling device 3 is arranged between the extracting table 2 and the clamping part 4, and the said extracting table 2 and the clamping part 4 are connected as a whole through the pulling device 3, and the said clamping part 4 is arranged on the left side of the processing tank 5, The inside of the treatment tank 5 is fixed with a cutting device 6, and the cutting device 6 is fixedly fastened to the middle position of the treatment tank ...

Embodiment 2

[0049] see figure 1 , the present invention provides a technical solution: a device for quickly stripping the insulation layer of a power cable, the structure of which includes a main body 1, an extraction table 2, a pulling device 3, a clamping member 4, a processing tank 5, and a cutting device 6 , a support block 7, a joystick 8, the upper end of the main body 1 is provided with a pull-out table 2, the pull-out table 2 is vertically fitted on the main body 1, the upper end of the pull-out table 2 is connected with a pulling device 3, the The pulling device 3 is arranged between the extracting table 2 and the clamping part 4, and the said extracting table 2 and the clamping part 4 are connected as a whole through the pulling device 3, and the said clamping part 4 is arranged on the left side of the processing tank 5, The inside of the treatment tank 5 is fixed with a cutting device 6, and the cutting device 6 is fixedly fastened to the middle position of the treatment tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com