Sedimentation device and application thereof

A settling device and settling hopper technology, which is applied to the feeding/discharging device of the settling tank, settling separation, settling tank, etc., can solve the problem of increasing the work intensity of personnel, increasing the investment and maintenance expenditure of some equipment for sludge settling, and reducing sewage Solve problems such as equipment use efficiency, achieve the effect of simple structure, convenient production, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

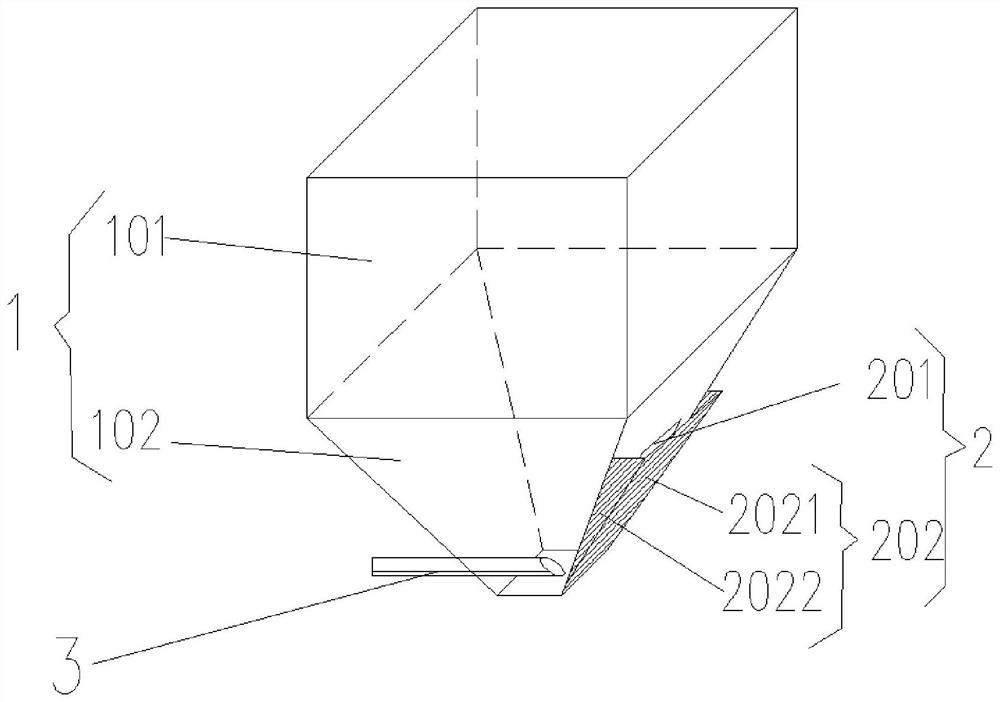

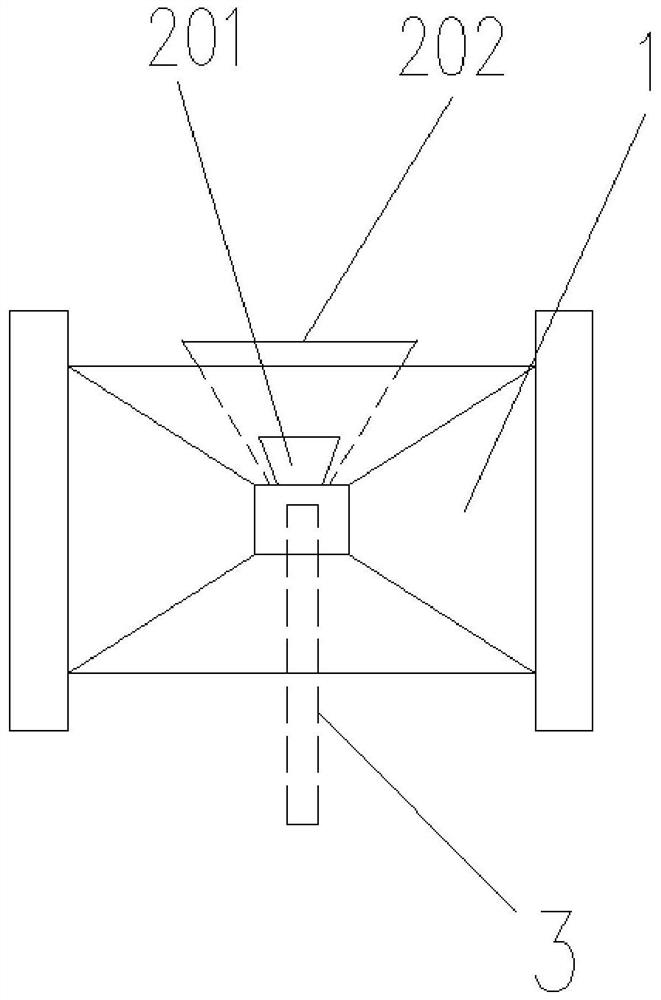

[0036] Please refer to figure 1 and figure 2 As shown, a sedimentation device, in this embodiment, the sedimentation device includes a sedimentation hopper 1, the side wall of the sedimentation hopper 1 is provided with a sludge inlet structure 2, and the sludge inlet structure 2 forms a mud-water mixture that enters the interior of the sedimentation hopper 1 The mud-water mixture enters the sedimentation hopper 1 through the sludge liquid inlet structure 2 for sedimentation and forms clear liquid and sedimentation sludge.

[0037] Among them, as an improvement to the sludge inlet structure 2, such as figure 1 and figure 2 As shown, the sludge inlet structure 2 includes a sludge inlet 201, which is provided on the side wall of the sedimentation hopper 1, and the sludge inlet 201 is used to introduce the mud-water mixture into the sedimentation hopper 1 through the sludge inlet 201. In this embodiment, the sludge inlet 201 is arranged on the side wall of the sludge settlin...

Embodiment 2

[0043] Please refer to figure 1 and figure 2 As shown, a settling device, in this embodiment, the settling device includes a settling hopper 1, the side wall of the settling hopper 1 is provided with a sludge liquid inlet structure 2, and the mud-water mixture in the pool body sedimentation area passes through the sludge liquid inlet structure 2 into the settling hopper 1 for sedimentation, and the mud-water mixture settles to form clear liquid and sedimentation sludge.

[0044] Wherein, as an improvement to the sedimentation bucket 1, such as figure 1 and figure 2 As shown, the settling hopper 1 includes a mud-water separation chamber 101 , and a sludge settling chamber 102 communicating with the mud-water separation chamber 101 is provided at the lower part of the mud-water separation chamber 101 . The sludge settling chamber 102 is a prism structure with a large top and a small bottom, and the sludge liquid inlet structure 2 is arranged on the side wall of the prism st...

Embodiment 3

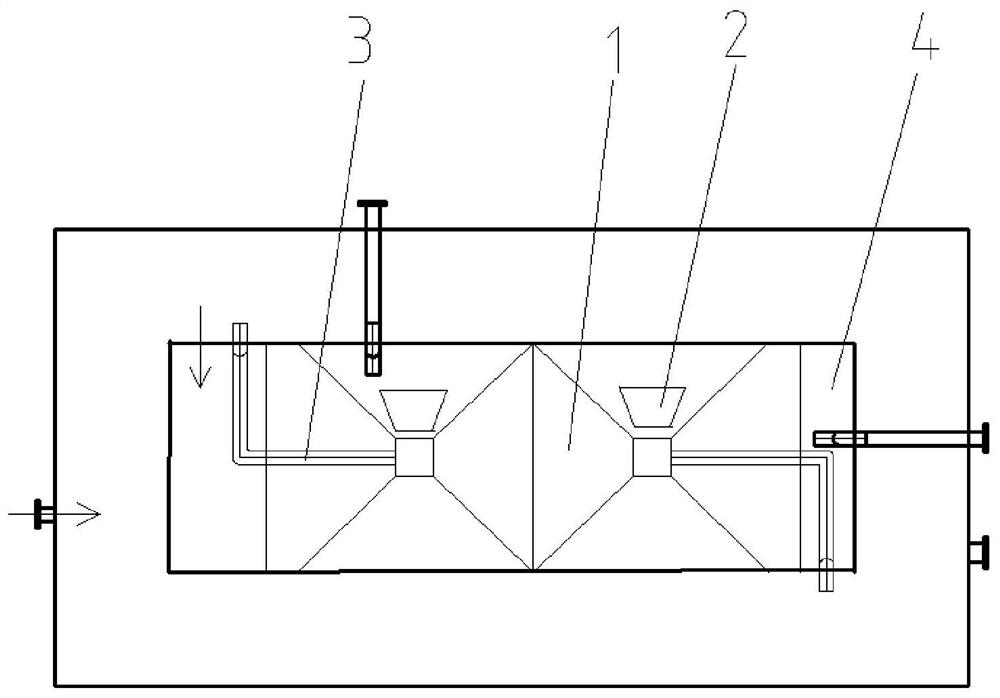

[0058] The present invention also provides an application of a settling device. One, two, three, ... several settling devices are installed side by side in the settling process of a sewage treatment system (such as a physical sewage treatment system or a biochemical sewage treatment system). In zone 4, connect the liquid discharge port at the upper end of the sedimentation bucket 1 to the clear liquid treatment equipment; connect the sludge return pipe 3 of the sedimentation device to the sludge return device, and part of the settled sludge will be transported back to the anaerobic tank through the sludge return device. In the pool or anoxic pool, another part of the settled sludge is transported to the sludge treatment equipment for treatment.

[0059] In this example, if image 3 As shown, there are two sedimentation devices in the biochemical sewage treatment system. , when the sedimentation device is applied in the sewage treatment system, the sedimentation bucket 1 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com