A detachable cross-flow filter for magnesite and its filtering method

A filter and magnesite technology, which is applied to chemical instruments and methods, separation methods, filtration separation, etc., can solve the problems of large area of filter elements, large labor costs, and reduced filtration efficiency, so as to reduce labor costs. Strength, convenient and fast disassembly and assembly, and the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

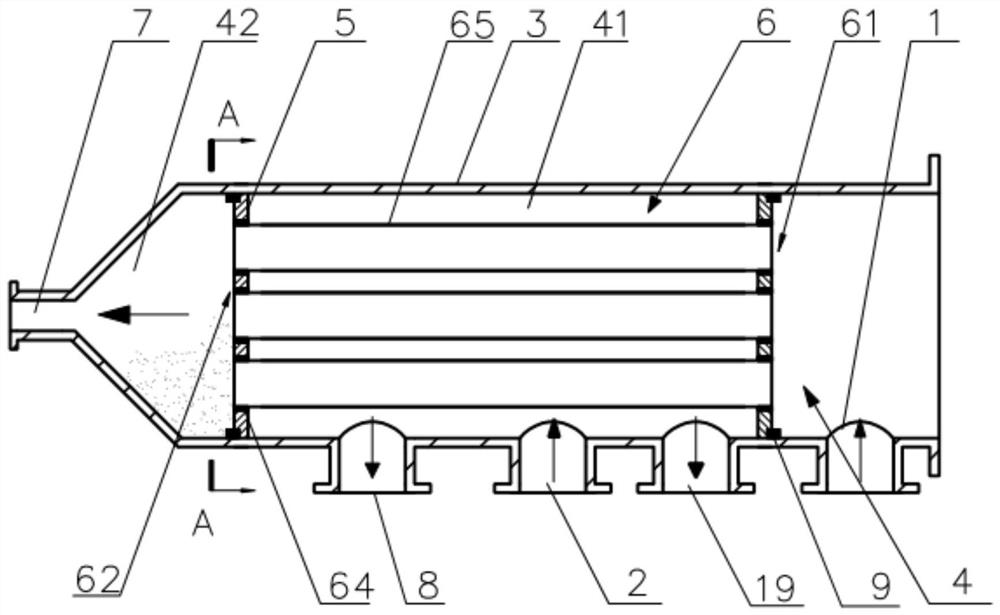

[0038] like figure 1 , 2 , 3, 4, 5, a detachable cross-flow filter for magnesite, including a filter housing 3 with a raw liquid inlet 1 and a filtrate outlet 19, and a filter cavity 4 inside, so The raw liquid inlet is set at one end of the filter shell, and the filtrate outlet is set on the outer surface of the filter shell. And the orifice plate 5 of the filter material storage area 42, the orifice plate 5 and the filter housing 3 are sealed by the orifice plate sealing ring 9, and the two orifice plates are provided with mounting holes 51 for fixing the filter tube system. The system is fixed between the two orifice plates; the filter tube system inlet 61 is connected to the raw liquid inlet, the filter tube system outlet 62 is connected to the filter material storage area, and the filter material storage area is provided with a filter material discharge port 7, and one is connected to the filter processing area. The backwash port 2 also includes a raw liquid inlet contr...

Embodiment 2

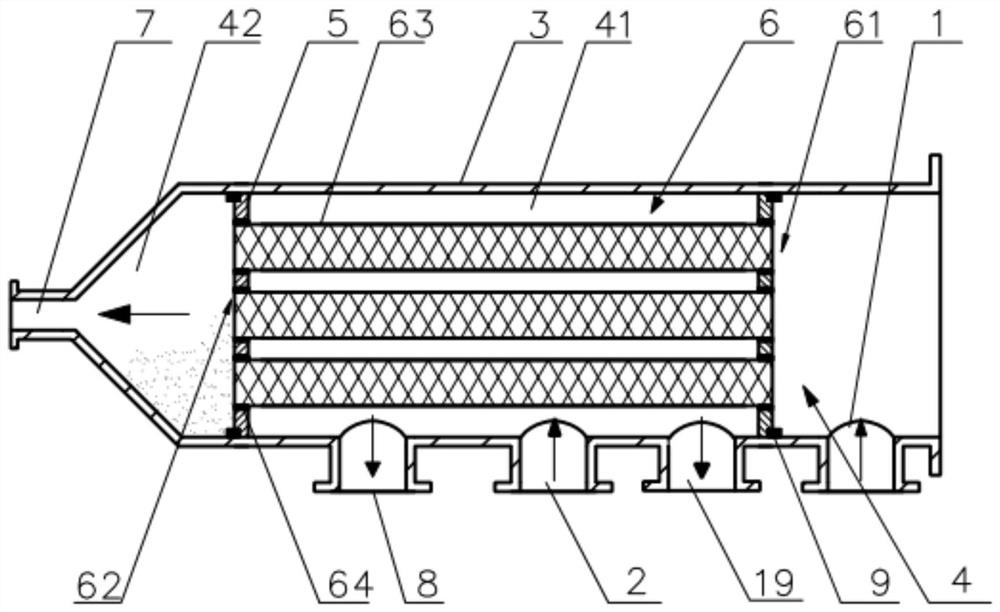

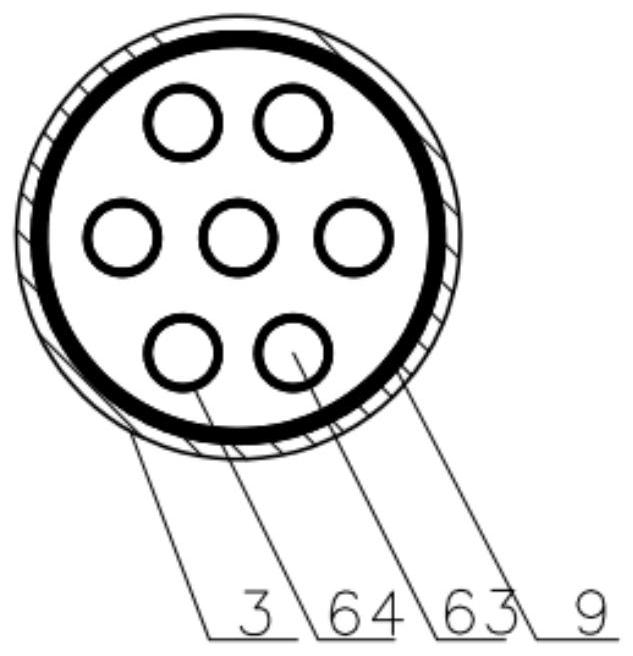

[0053] like Image 6 , 7 , 8, 9, in order to facilitate disassembly and cleaning, the filter mesh tube is not directly installed in the installation hole on the orifice plate, but a sub-filter unit composed of a small orifice plate and a filter mesh tube is installed. At this time, the orifice plate 5 set on the filter housing 3 can be called the primary orifice plate, and the small orifice plate set on the primary orifice plate can be called the secondary orifice plate 10 . The diameter should be compatible with the aperture of the primary orifice plate, and the number of the secondary mounting holes 11 on the secondary orifice plate 10 is generally not more than 400. The sealing between the orifice plate 5 and the filter housing 3 and between the orifice plate 5 and the filter mesh tube can be sealed by a filter sealing ring 64 . The sealing between the primary orifice plate and the secondary orifice plate 10 can be sealed by a filter sealing ring 64 . In this embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com