Automatic plasma bag cleaning and breaking system and cleaning method

A plasma bag and bag breaking technology, which is applied in the field of automatic plasma bag cleaning and bag breaking system and cleaning, can solve the problems of wasting water for injection, difficult to ensure cleaning effect, equipment and pipeline pollution and cleaning, etc., and achieves the effect of avoiding wasting water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

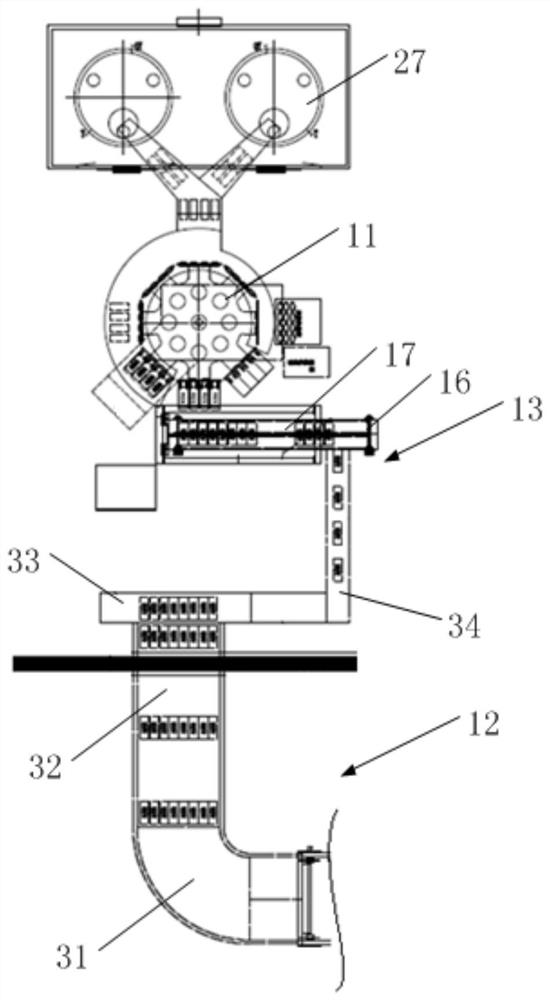

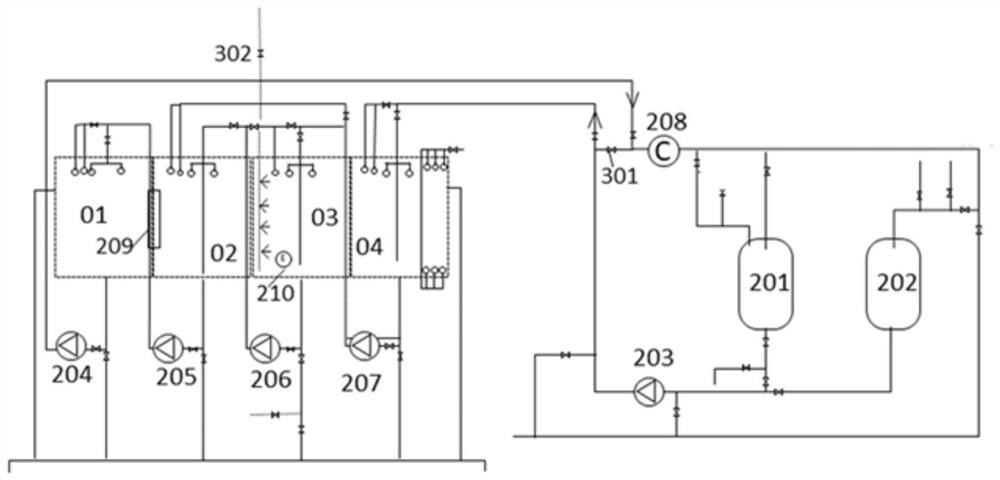

[0073] The invention provides an automatic plasma bag cleaning and bag breaking system, such as Figures 1 to 3 As shown, including: blood plasma bag cleaning subsystem, delivery mechanism 12 and bag breaking bag system;

[0074] The plasma bag cleaning subsystem is used to clean the outside of the plasma bag. After the cleaning is completed, the cleaned plasma bag is transferred to the bag breaking system through the delivery mechanism;

[0075] The bag loading and breaking system includes: bag loading machine 13 and bag breaking machine 11; bag loading machine 13 is used to transfer plasma bags to bag breaking machine 11;

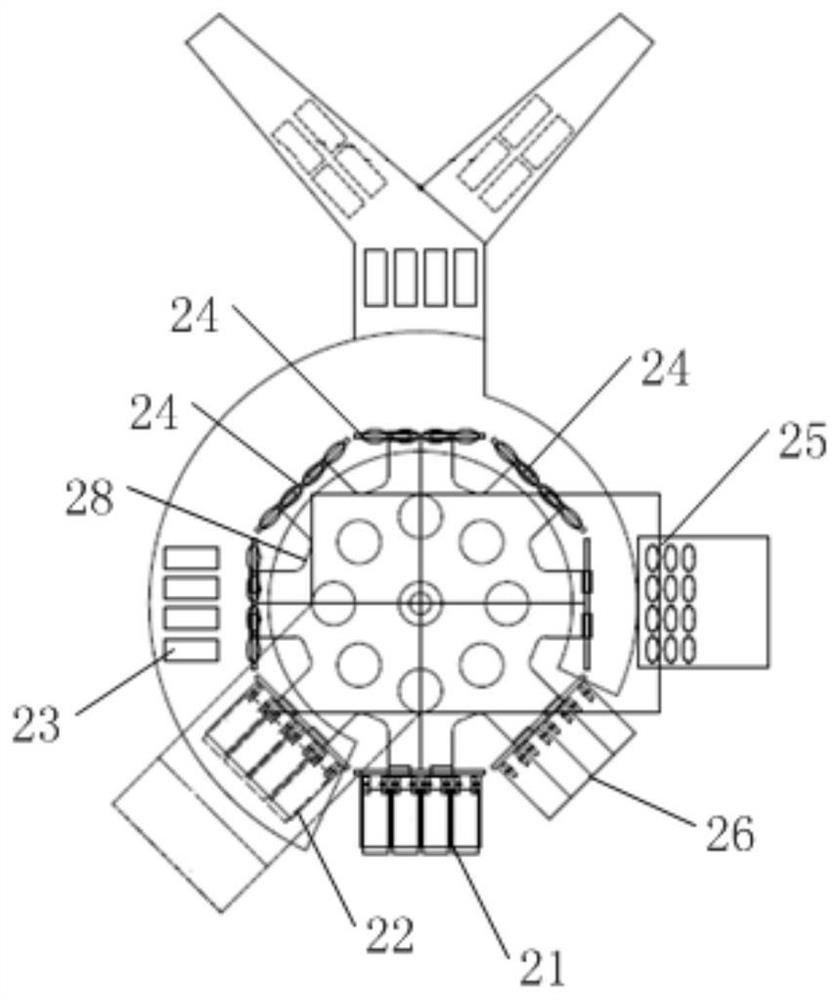

[0076] The bag breaking machine 11 includes: a turntable mechanism 28; a bag receiving station 21, a bag cutting station 22, an ice dropping station 23, a dripping station 24, a bag lowering station 25 and a reset station are uniformly arranged around the turntable mechanism 28. bit 26;

[0077] The bag receiving station 21 is used to receive the plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com