Drilling device for electronic component machining and production

A technology of electronic components and drilling devices, which is applied in the direction of positioning devices, boring/drilling, metal processing equipment, etc., and can solve the problem of unstable clamping of electronic components, poor functionality and practicability, and limited clamping range and other issues to achieve the effect of ensuring accuracy, enhancing practicability, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

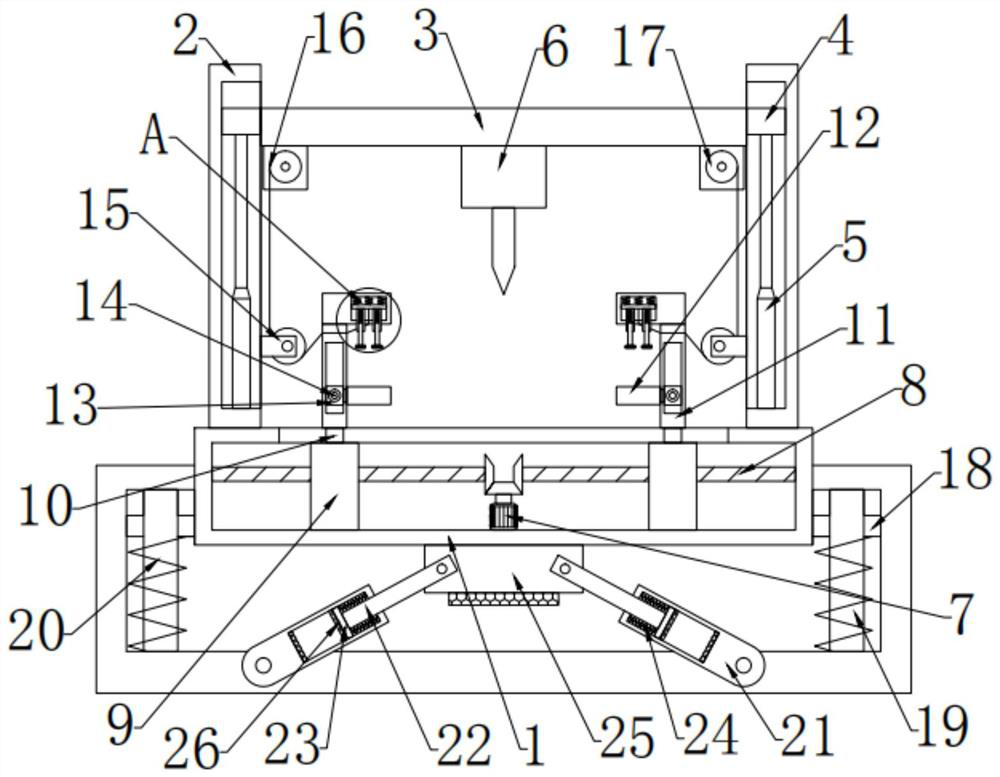

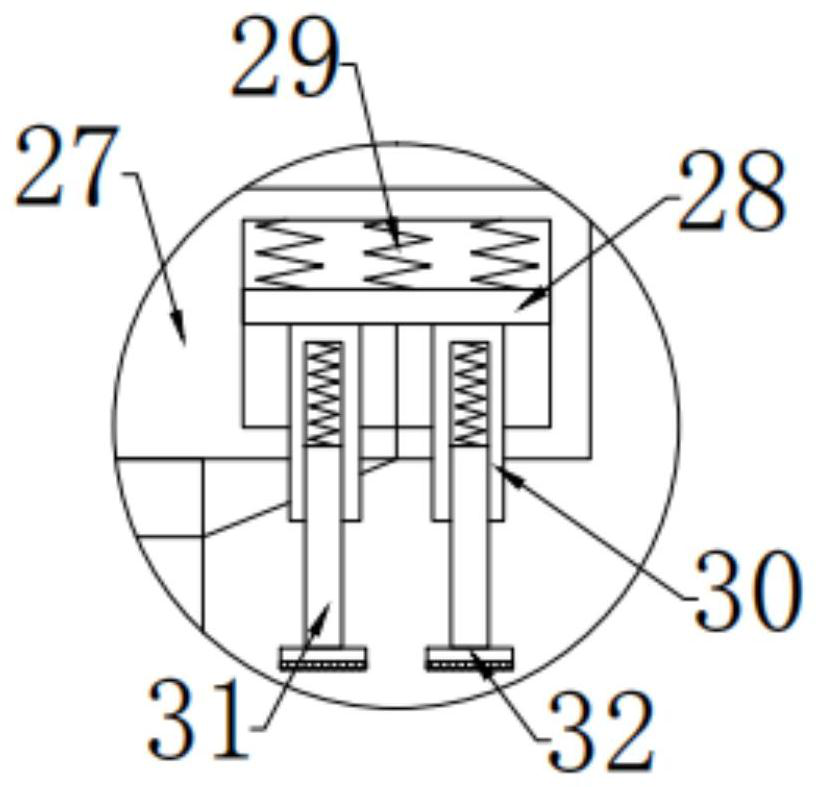

[0025] See Figure 1-4 In an embodiment of the present invention, a drilling device for processing and production of electronic components includes an operating table 1. The top of the left and right ends of the operating table 1 are fixedly connected with support plates 2, and the support plates 2 on both sides A drilling mechanism is arranged between the drilling mechanism, a fixing mechanism is arranged on the lower side of the drilling mechanism, a transmission mechanism is arranged between the fixing mechanism and the drilling mechanism, a base is arranged at the bottom of the operating table 1, and the base is connected to the operating A shock absorption mechanism is arranged between the stations 1.

Embodiment 2

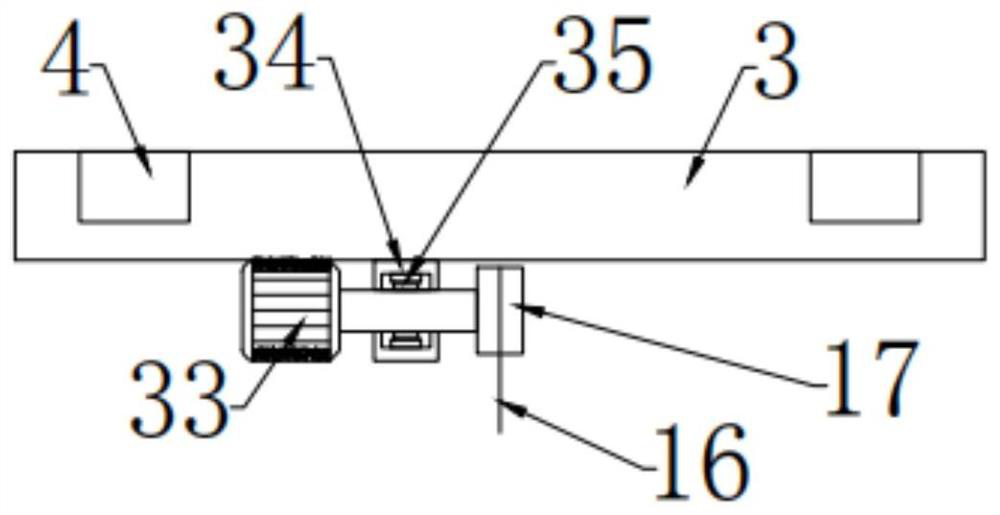

[0027] In this embodiment, the drilling mechanism includes a movable plate 3. Both left and right sides of the movable plate 3 are fixedly connected with a slider 4 that is slidably connected to the support plate 2. The bottom end of the slider 4 is connected to the support plate 2. A first telescopic rod 5 is fixedly connected therebetween, and a drill 6 is bolted to the bottom of the movable plate 3.

[0028] In this embodiment, the fixing mechanism includes a first motor 7 bolted to the inner side of the console 1, and both left and right sides of the first motor 7 are provided with threaded rods 8 that are rotatably connected to the console 1. The rod 8 and the output end of the first motor 7 are meshed and connected with a bevel gear. The outer sides of the threaded rods 8 on both sides are threadedly connected with a movable block 9, and the top of the movable block 9 is fixedly connected with a supporting block 10, the The support block 10 is slidably connected to a chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com