Mounting method and shape correcting device for wind power tower drum door frame and drum body reinforcing plate

A technology for wind power towers and installation methods, which is applied to metal processing equipment, gas flame welding equipment, and other manufacturing equipment/tools, etc., which can solve problems such as difficulty in ensuring a first pass rate, high operating intensity, and long welding time, and reduce The effects of welding time and working intensity, avoiding the risk of working at heights, and saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for installing a door frame of a wind power tower and a reinforcement plate of a cylinder body, comprising the following steps:

[0046] S1. Make cylinder reinforcement plate:

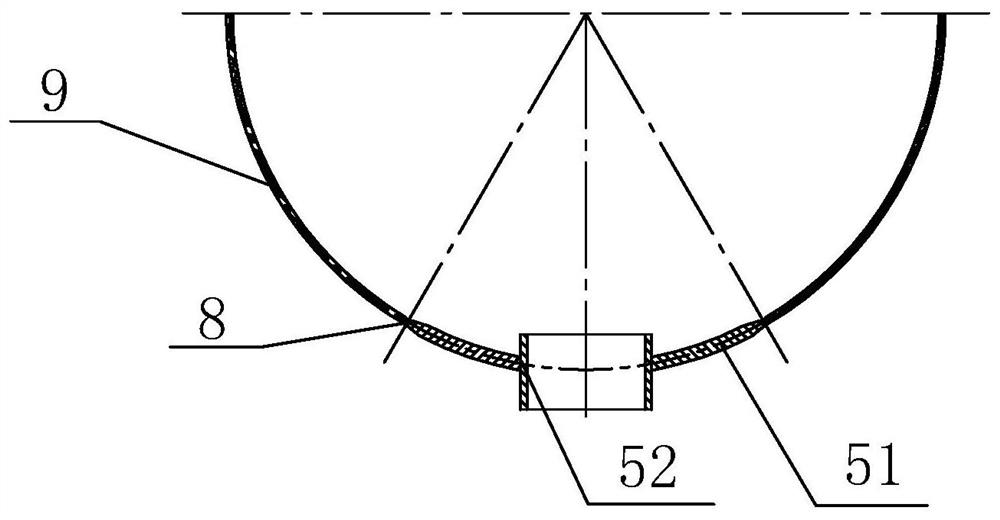

[0047] Precisely set out a piece of plate whose length dimension is 1 / 6 of the circumference of the bottom of tower cylinder 9 and whose height dimension is less than the height of the embedded cylinder section, blanking by CNC flame cutting machine, semi-automatic flame cutting machine cutting thinning transition and beveling Finally, the radian of the cylinder is used as the curvature of the cylinder reinforcement plate, and the sheet is rolled and formed by rolling equipment to obtain the cylinder reinforcement plate 51;

[0048] S2. Cut the door frame hole:

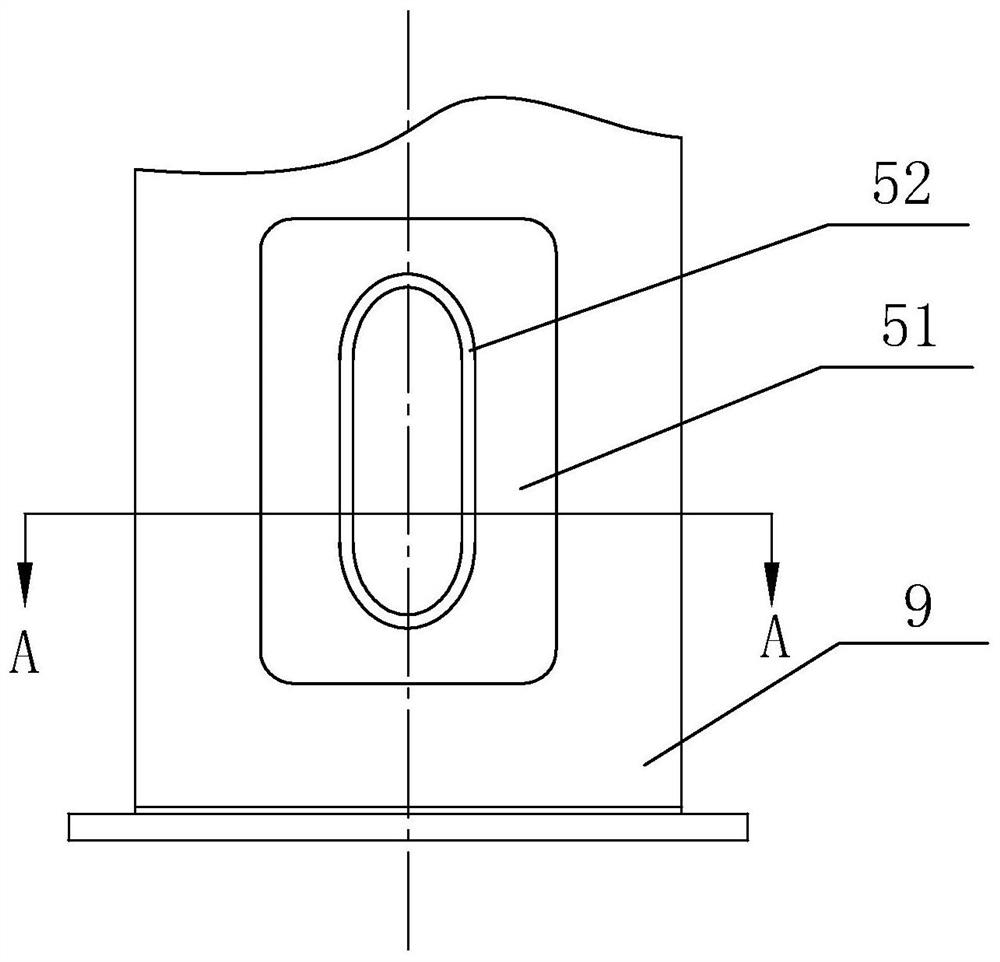

[0049] NC programming is carried out by drawing the width and height dimensions of the door frame 52, using a CNC flame cutting machine to cut in the middle of the reinforcement plate of the cylinder body, and opening the door...

Embodiment 2

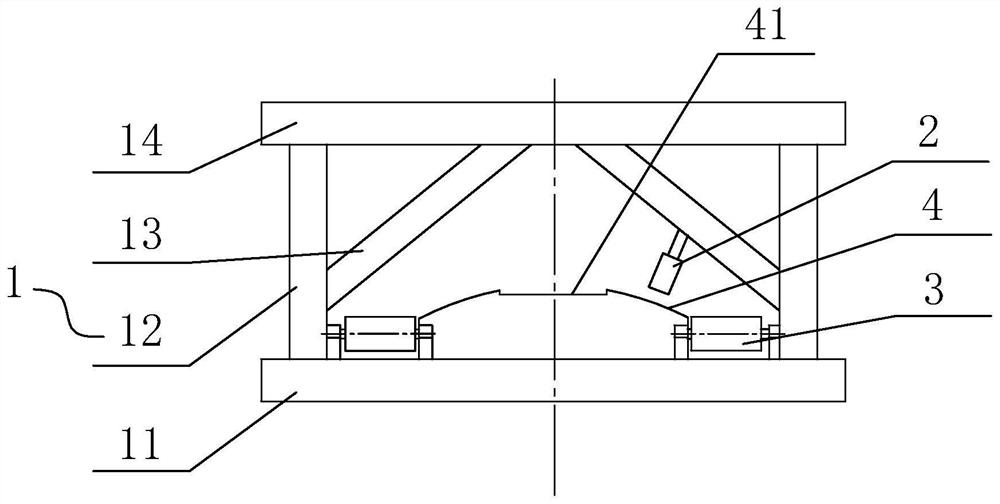

[0059] An orthopedic device for a door frame of a wind power tower tube and a reinforced plate of a cylinder body, the orthopedic device is an orthopedic device used when the circular arc of the reinforced plate of the cylinder body is corrected, and includes a bracket 1, an orthopedic device 2, a rolling device 3 and a correcting tire mold 4,

[0060] The support includes a base 11, a pillar 12, an oblique support 13 and a top plate 14, a pillar is connected between the base and the left and right ends of the top plate, one end of the oblique support is connected with the pillar, and the other end of the oblique support is connected with the upper top plate; The base and the top plate are steel plates with a thickness greater than or equal to 50mm; the pillars and diagonal supports are made of square steel or round steel pipes;

[0061] The orthopedic device is a jack, and the jack is arranged on an oblique support;

[0062] The rolling device is a roller 31. There are at lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com