Steering conveying rail and automatic grinding production line

A conveying track and production line technology, which is applied in the field of grinding processing, can solve the problems of single-sided grinding of workpieces to be ground, slow production speed, complex structure, etc., and achieves the effects of simple structure, increased output ratio, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

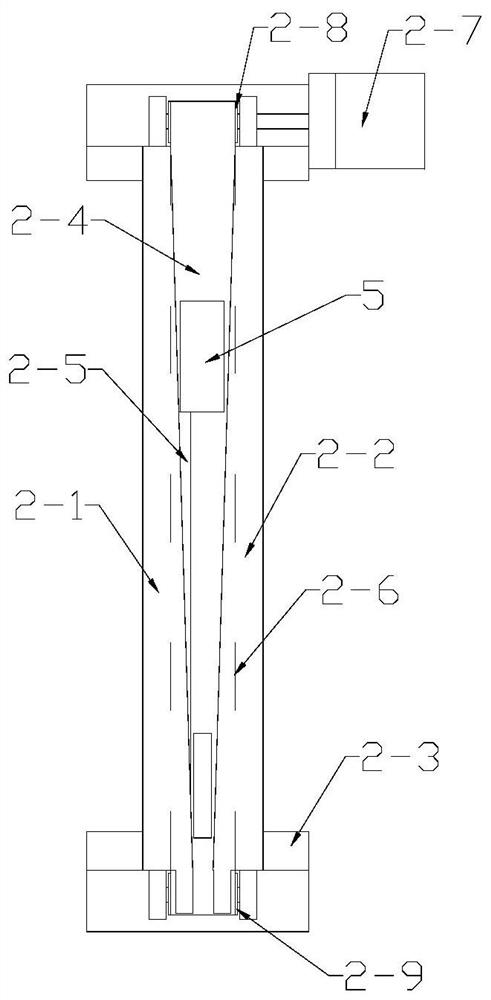

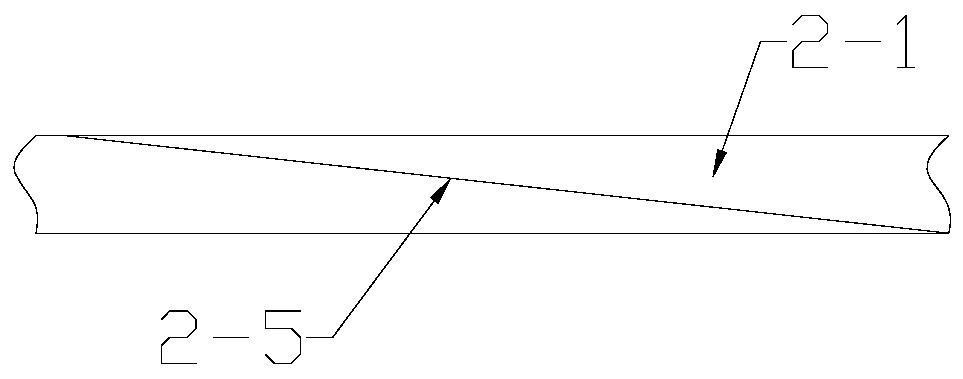

[0031] Such as figure 1 with 2 As shown, a steering conveyor track includes a first limit baffle 2-1 and a second limit baffle 2-2 arranged at intervals, and the first limit baffle 2-1 and the second limit baffle 2 Both ends of -2 are fixed on the support base 2-3. Between the first limiting baffle 2-1 and the second limiting baffle 2-2, a workpiece transmission channel 2-4 is formed, and the first limiting baffle 2-1 and the second limiting baffle 2-2 The inner walls are gradually inclined inward along the conveying direction of the workpiece 5, and the conveying channel 2-4 of the workpiece is gradually narrowed along the conveying direction of the workpiece 5. Only allow a single workpiece 5 to pass through vertically. The inner sidewall of the first limit baffle 2-1 is provided with an upwardly inclined turning slope 2-5 along the conveying direction of the workpiece 5, and the turning slope 2-5 starts from the lower end of the first limit baffle 2-1 along the conveying...

Embodiment 2

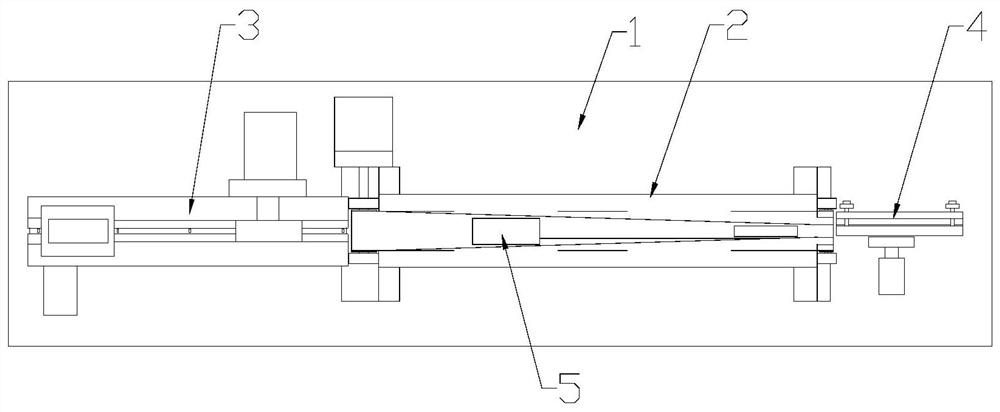

[0035] Such as Figure 3-5 As shown, a kind of automatic grinding production line comprises workbench 1, is installed on the workbench 1 and implements the above-mentioned steering conveying track 2, and the feeding end of diverting conveying track 2 is provided with the first grinding device 3, and the feeding end is provided with There is a second grinding device 4, and the second grinding device 4 includes the first grinding wheel 4-5 and the single-sided grinding guide rail that is positioned at the first grinding wheel 4-5, and the feeding end of the single-sided grinding guide rail is connected to the transfer track The feeding ends of 2 are connected, and the first grinding device 3 includes a machine base 3-1 arranged on the workbench 1. A workpiece conveying mechanism is arranged on the machine base 3-1, and a second grinding machine is arranged above the workpiece conveying mechanism. Wheel 3-10, the feeding end of the workpiece conveying mechanism is provided with f...

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 4 As shown, the workpiece conveying mechanism includes a conveying chain 3-3 arranged on the support 3-1, a driving wheel driven by the first reduction motor 3-2 is installed at one end of the support 3-1, and a driven wheel is installed at the other end. A transmission conveying chain 3-3 is set between the driving wheel and the driven wheel, and a plurality of stoppers 3-5 for pushing the workpiece 5 are fixed at intervals on the conveying chain 3-3, and the distance between adjacent stoppers 3-5 is greater than that of a single The length of the workpiece 5. The upper ends of the frame 3-1 on both sides of the conveyor chain 3-3 are fixed with a slide rail 3-6, the slide rail 3-6 is arranged along the conveying direction of the workpiece 5, and the slide rail 3-6 is close to the side of the conveyor chain 3-3 An L-shaped support groove 3-7 is provided, and the end of the workpiece 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com