Mold plate assembly and mold

A template and component technology, applied in the field of template components and molds, can solve the problem of poor heating or cooling effect of the mold waterway, and achieve good effect and good overall temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] The second embodiment of the present invention also proposes a mold, including the above-mentioned template assembly.

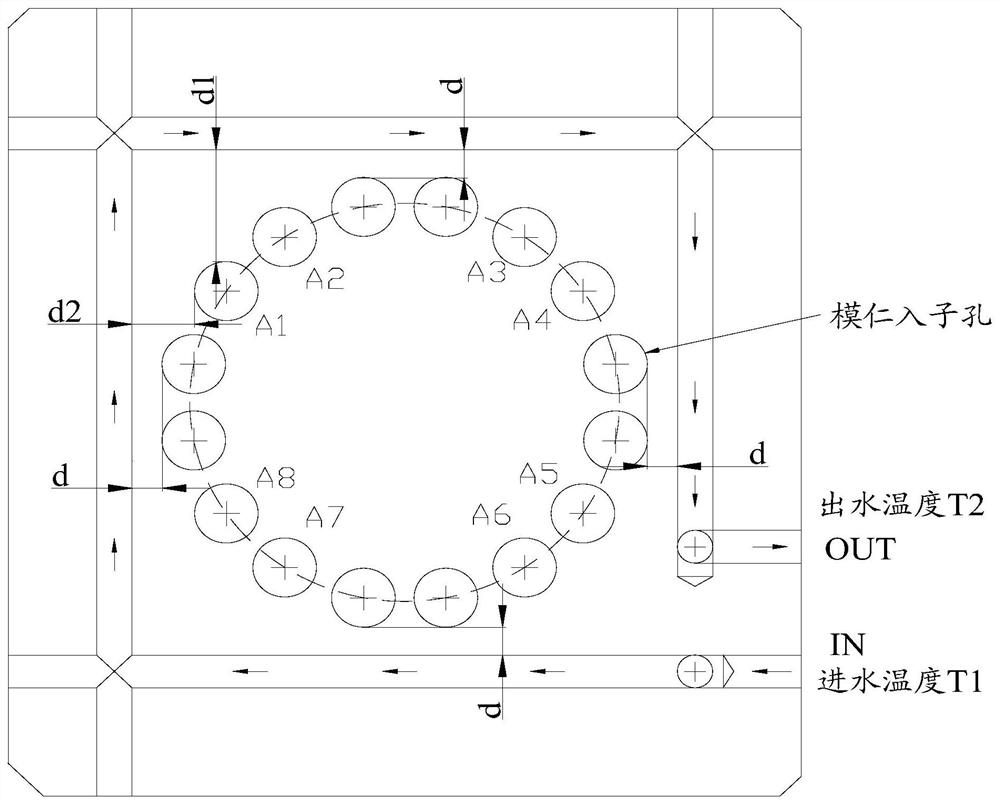

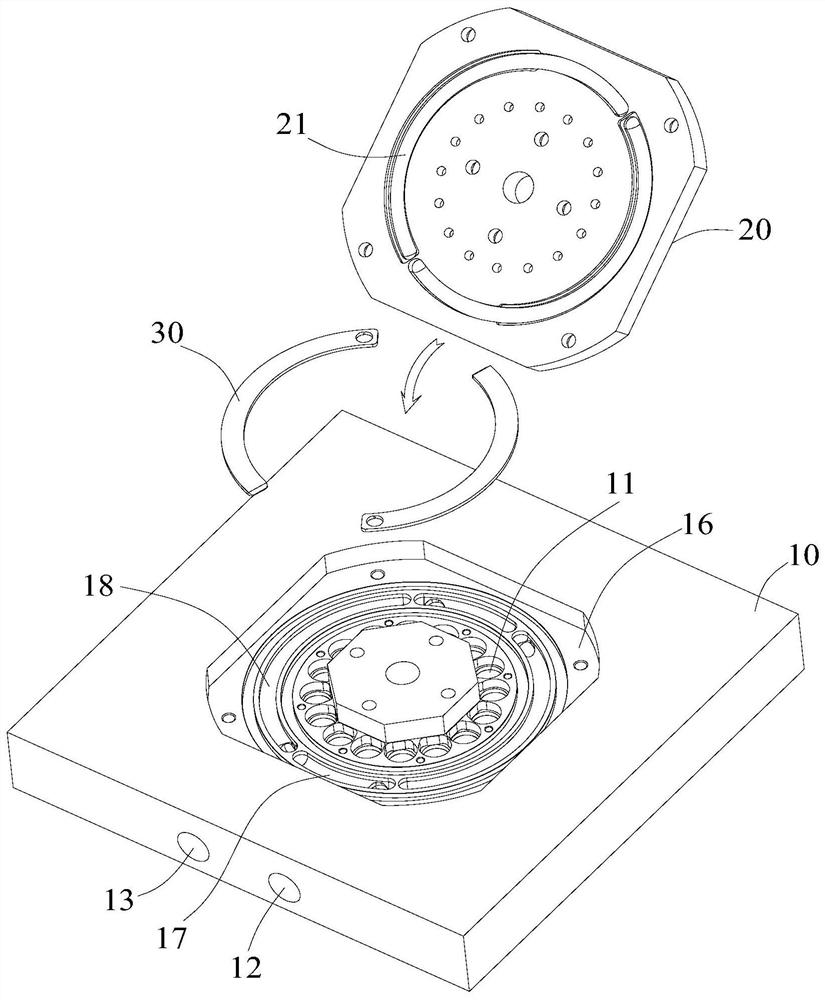

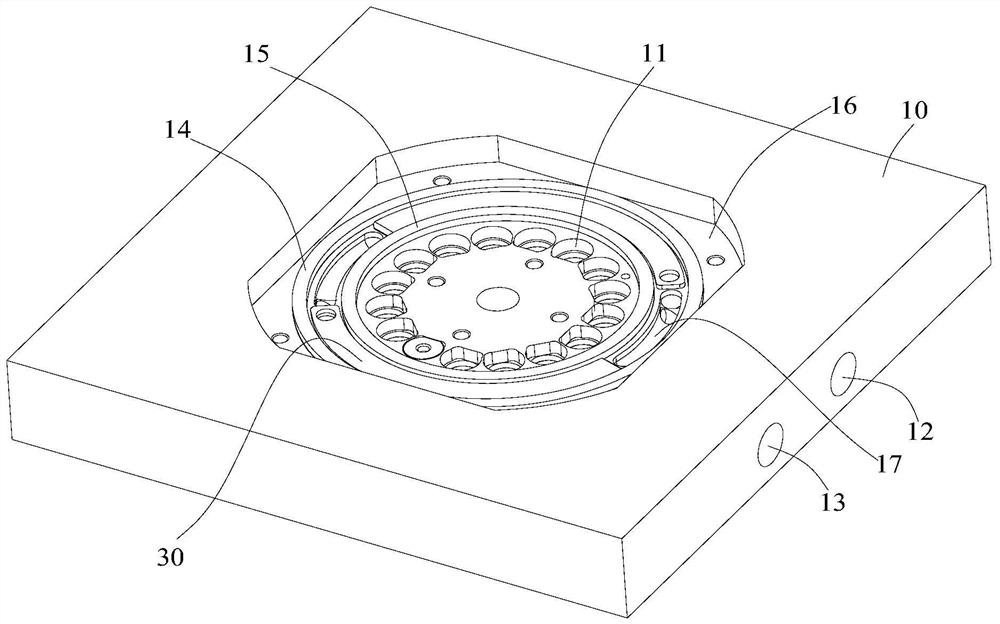

[0051] To sum up, the mold in the above-mentioned embodiment of the present invention, by arranging the waterway structure on the second circumference, and the second circumference is set concentrically with the first circle where the inlet hole is located, ensures that the distance between each hole and the water is transported. All are equal, the number of holes is not limited, and multi-holes can be evenly heated or cooled; in addition, the waterway structure of this application adopts a double-layer waterway design, and the upper and lower waterways are separated by water barriers, so that the upper and lower waterways are separated by a partition The water sheet can perform heat exchange to achieve the purpose of temperature compensation, with good heating or cooling effect and good overall temperature control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com