Real-time monitoring close-fitting checker for railway turnout switch rail or point rail state

A close-fit checker and real-time monitoring technology, which is applied to railway vehicle shape measuring instruments, railway signals, railway car body parts, etc., can solve the problems of large number of installation device parts, jamming of display rods, and cumbersome on-site installation, etc., to achieve Effect of improving protection performance and simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand that the technical solutions of the present invention can be implemented, the present invention will be further described below in conjunction with specific examples, but the given examples are only used as illustrations of the present invention, not as limitations of the present invention.

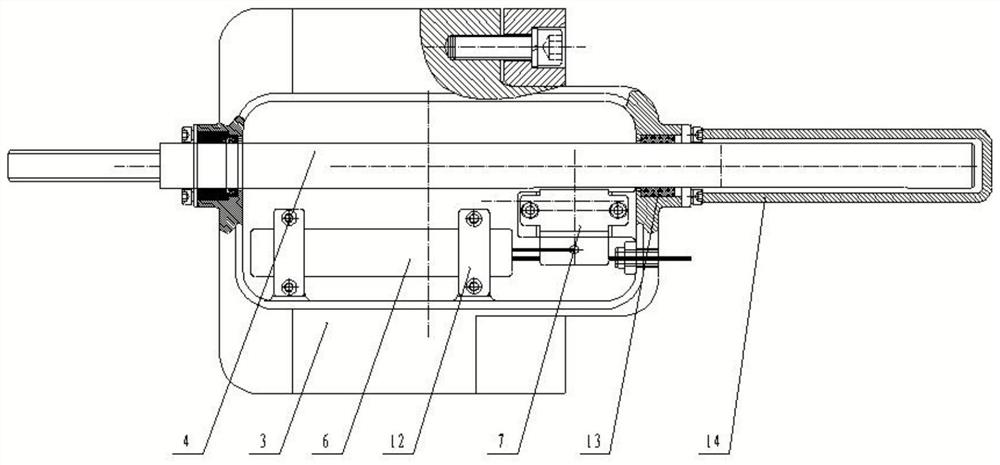

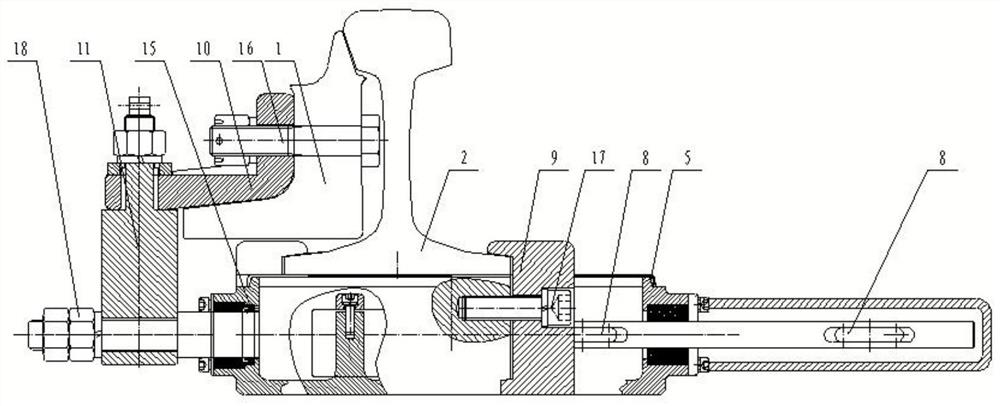

[0033] Such as figure 1 The shown is a real-time monitoring close-fitting checker for the state of the point rail or core rail of a railway turnout, including a bottom case 3, a display rod 4, a machine cover 5, an acquisition extension 6, a sensor 7, an information magnetic strip 8, a pressure plate 12, and a copper sleeve 13 and cover cylinder 14; the indicating rod 4 is a circular rod installed on the bottom case 3, and a copper sleeve 13 and a Y-shaped sealing ring 15 are placed at the interface between the bottom case 4 and the indicating rod 3 for lubrication and protection; 4 is equipped with an information mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com