Modified silicone oil water repellent agent and preparation method thereof, and waterproof mortar prepared from water repellent agent and preparation method thereof

A technology of waterproof mortar and hydrophobic agent, applied in the fields of modified silicone oil hydrophobic agent and preparation method, waterproof mortar and preparation method, can solve the problems of low early strength, general waterproof effect, poor impermeability, etc., and improve impermeability , excellent impermeability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw material formula of the modified silicone oil hydrophobic agent is shown in Table 1 below.

[0021] The hydrophobic agent raw material of table 1 embodiment 1

[0022] raw material Polymethylsiloxane 1-heptene Isopropanol Chloroplatinate Chlorobutanol content 70 24 1 5

[0023] The preparation method of the hydrophobic agent comprises the following steps: 70 parts of polymethylsiloxane and 24 parts of 1-heptene are added into a four-necked flask equipped with a stirrer, a thermometer and a condenser tube, and placed in a constant temperature oil bath Stir at 110°C, add 1 part of isopropanol chloroplatinate dropwise during the process, react for 2 hours, cool to 70°C, add 5 parts of chlorobutanol and continue stirring for 1 hour to prepare a modified silicone oil hydrophobic agent.

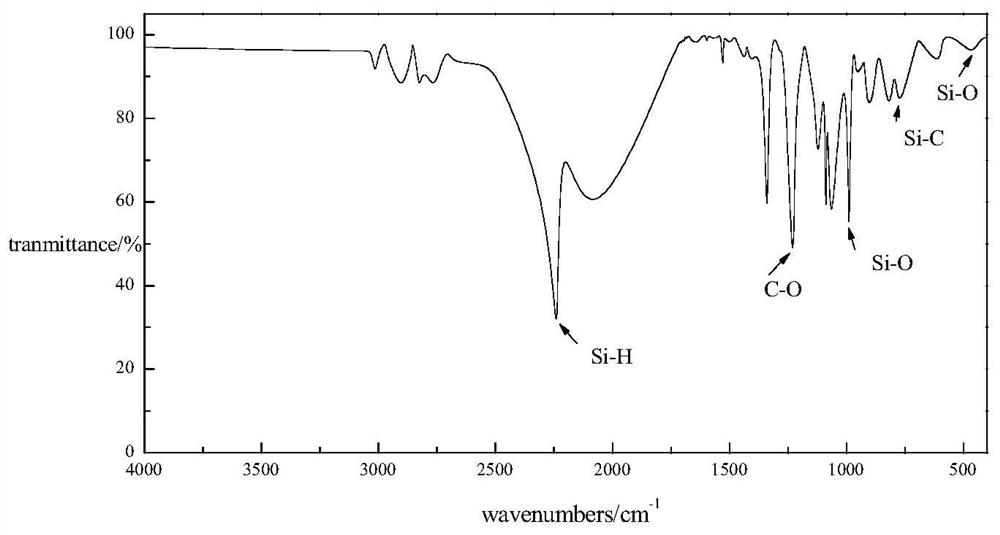

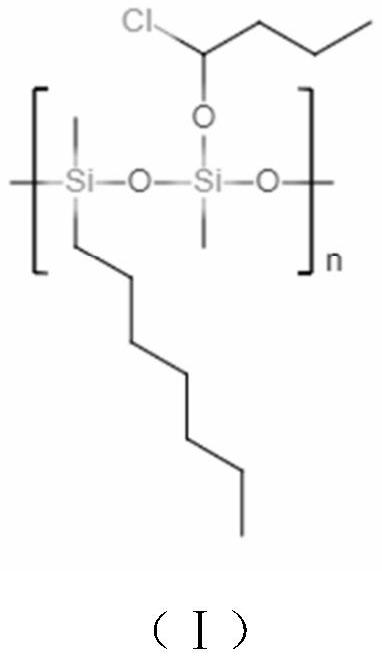

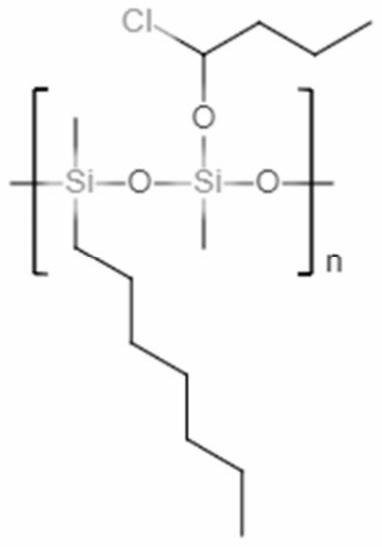

[0024] The hydrophobic agent is carried out structural detection, the obtained result is shown in (I), and the detection result is as follows figure ...

Embodiment 2

[0034] The raw material formula of the modified silicone oil hydrophobic agent is shown in Table 3 below.

[0035] The hydrophobic agent raw material of table 3 embodiment 2

[0036] raw material Polymethylsiloxane 1-heptene Isopropanol Chloroplatinate Chlorobutanol content 69 20 1 10

[0037] The preparation method of the hydrophobic agent comprises the following steps: 69 parts of polymethylsiloxane and 20 parts of 1-heptene are added into a four-necked flask equipped with a stirrer, a thermometer and a condenser tube, and placed in a constant temperature oil bath Stir at 110°C, add 1 part of isopropanol chloroplatinate dropwise during the process, react for 2 hours, cool to 70°C, add 10 parts of chlorobutanol and continue stirring for 1 hour to prepare a modified silicone oil hydrophobic agent.

[0038] The waterproof mortar prepared by adopting the above-mentioned hydrophobic agent comprises the following raw materials:

[0039] The waterpr...

Embodiment 3

[0045] The raw material formula of the modified silicone oil hydrophobic agent is shown in Table 5 below.

[0046] The hydrophobic agent raw material of table 5 embodiment 3

[0047] raw material Polymethylsiloxane 1-heptene Isopropanol Chloroplatinate Chlorobutanol content 70 20 1 9

[0048] The preparation method of the hydrophobic agent comprises the following steps: 70 parts of polymethylsiloxane and 20 parts of 1-heptene are added to a four-necked flask equipped with a stirrer, a thermometer and a condenser tube, and placed in a constant temperature oil bath Stir at 110°C, add 1 part of isopropanol chloroplatinate dropwise during the process, react for 2 hours, cool to 70°C, add 9 parts of chlorobutanol and continue stirring for 1 hour to prepare a modified silicone oil hydrophobic agent.

[0049] The waterproof mortar prepared by adopting the above-mentioned hydrophobic agent comprises the following raw materials:

[0050] The waterproof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap