A bacteria adding device for the production of bio-organic fertilizer

A technology of biological organic fertilizer and power plant, which is applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve the problems of low work efficiency, no obvious improvement in production efficiency, low degree of automation, etc. Excellent effect of bacteria addition efficiency and automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

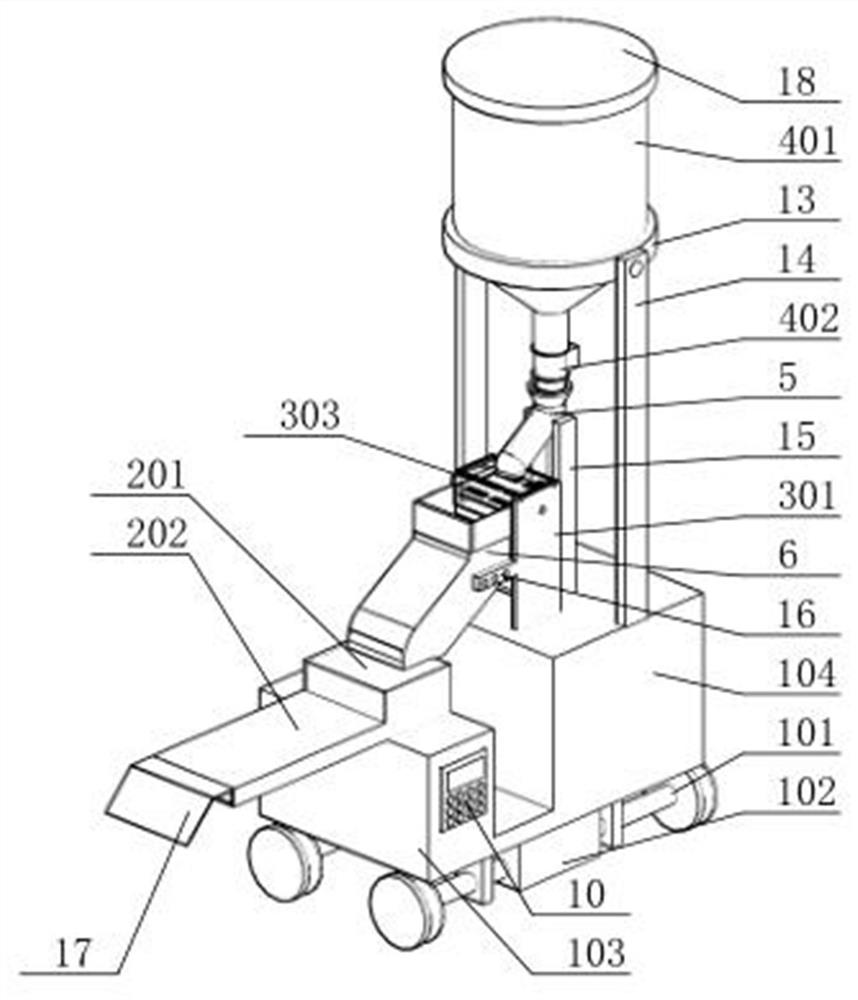

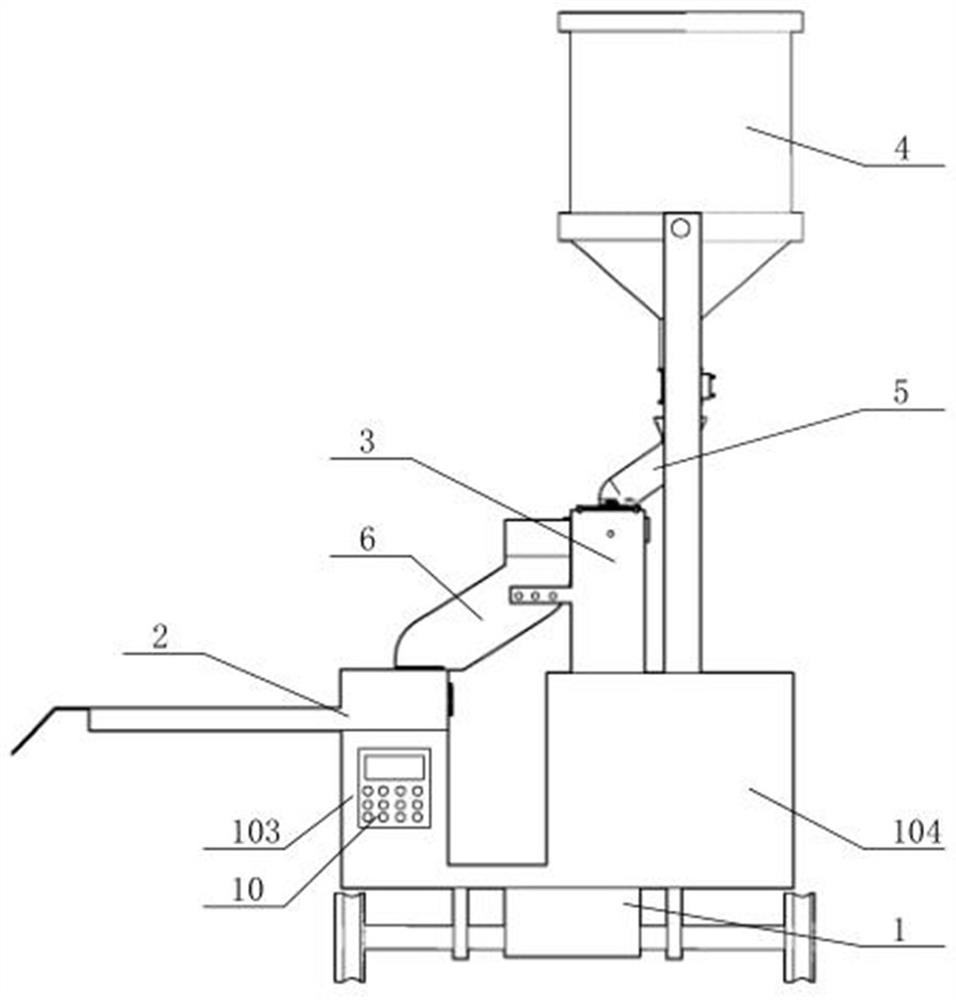

[0032] See figure 1 -6, a germacterial device for biological organic fertilizer production, including travel mechanism 1, a broadband mechanism 2, a weighing mechanism 3, and a material storage mechanism 4;

[0033] The traveling mechanism 1 includes a track wheel group 101, a power device 102, and a chassis. The bottom portion is fixedly mounted having the track wheel set 101, and the fixed-mounted power device 102 that can provide power is attached to the track wheel set 101, which can be driven by the power device 102. The track wheel group 101 is rotated, and the chassis includes a low stage body 103 and a high standing body 104, and the upper portion of the high ceiling 104 is fixedly mounted.

[0034]The material storage mechanism 4 includes a material storage tank 401, and the material storage tank 401 is fixedly coupled to the solenoid valve 402, which can employ the solenoid valve 402 of the large-diameter, which is provided with a first transmission pipe 5 corresponding ...

Embodiment 2

[0038] See figure 1 -7, a germici device for biological organic fertilizer production, is provided with track 11 with the track wheel group 101, and the rail 11 is fixedly mounted on one side of the fermentation tank 12, and the rail wheel group 101 in this apparatus is mounted On the track 11 such that the rail pullement 101 can be driven on the track 11 by power device 102, such that the strain can be uniformly spread in the fermentation groove 12.

Embodiment 3

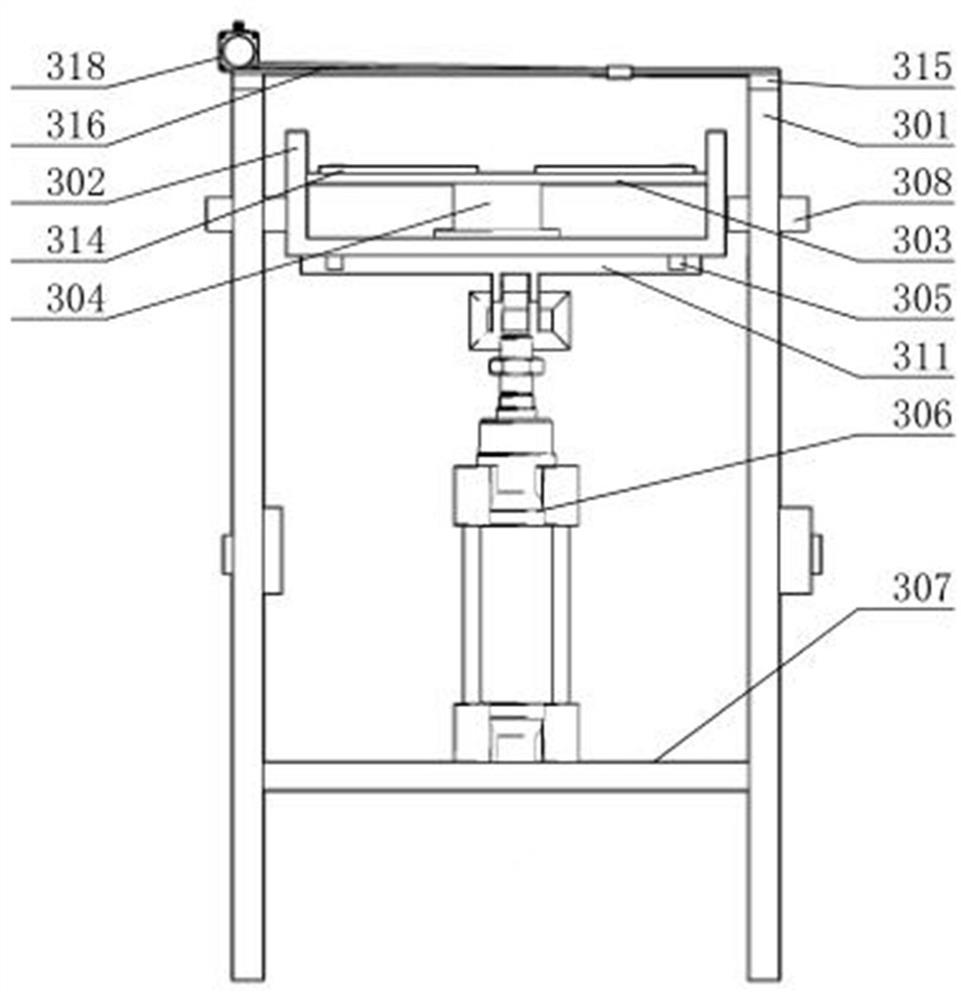

[0040] See figure 1 -7, a genus apparatus for biological organic fertilizer production, is basically the same as that of the example, further, and a set of rotating shaft 308 is fixed to the side surface of the weighing frame 302 corresponding to the side surface of the rotation table 301, rotating the shaft 308 Connecting on the rotation table 301, in this case, the rotation effect of the weighing frame is realized, and the inner wall of the weighing frame 302 is provided on the inner wall of the weighing frame 309, and the sliding groove 309 is fixed to the slide 309, and the slider is slidably connected. Inside the chute 309, the sliding installation requirements of the sheet 303 are realized;

[0041] The material storage tank 401 is fixedly mounted on the mounting ring frame 13, and the mounting ring frame 13 is fixedly coupled through the multi-set support post 14, and the first transmission pipe 5 is fixedly connected to the high platform 104 by the mounting frame 15, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com