Conductive bearing grease composition and preparation method thereof

A bearing lubrication and composition technology, which is applied in the field of conductive bearing grease composition and its preparation, can solve problems such as poor performance of grease, and achieve excellent lubricating performance, improved oxidation resistance, and excellent oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

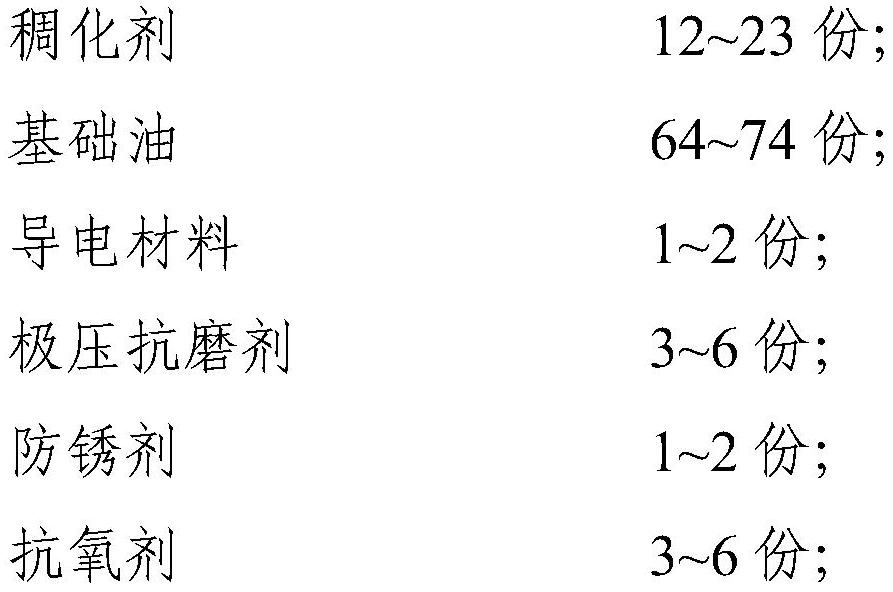

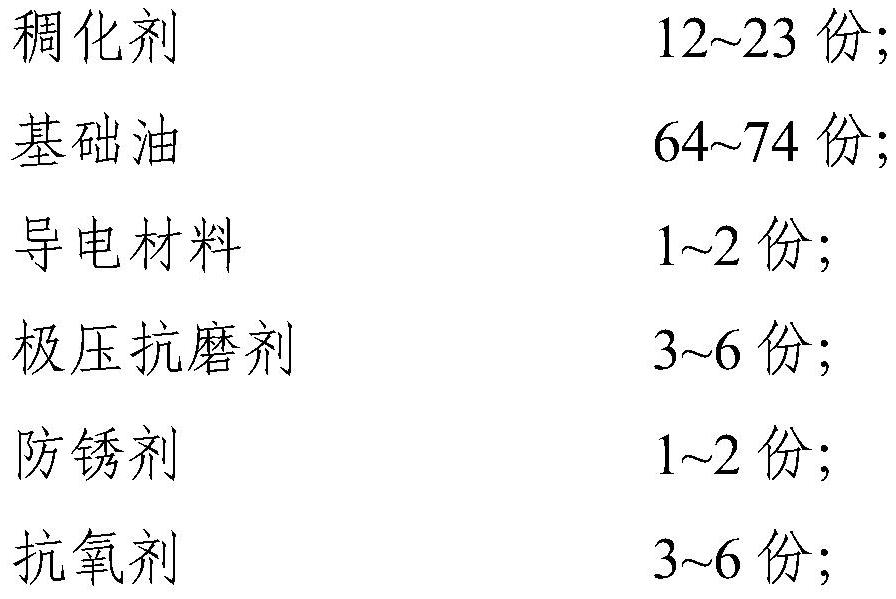

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the lubricating grease composition provided in this example: raise the temperature of 50% of the organic amine and the total base oil to 70-90°C, and simultaneously raise the temperature of 50% of the diisocyanate and the total base oil to 70-90°C, pour the two groups into The reaction kettle is mixed and stirred, heated to 90-100°C and kept at a constant temperature for 5-30 minutes. During the constant temperature process, the polymer-dispersed liquid crystal solution is added, and the temperature is slowly raised to the maximum temperature of 190°C at a rate of 5°C / min, and the temperature is kept at a constant temperature for 5-30 minutes. When the temperature drops to 100°C, add antioxidant, extreme pressure anti-wear agent, and rust inhibitor in turn, stir and cool down to 60°C, grind and degas to obtain the finished grease. The specific ratio of the grease composition provided in this embodiment is shown in Table 1 below.

Embodiment 2-8

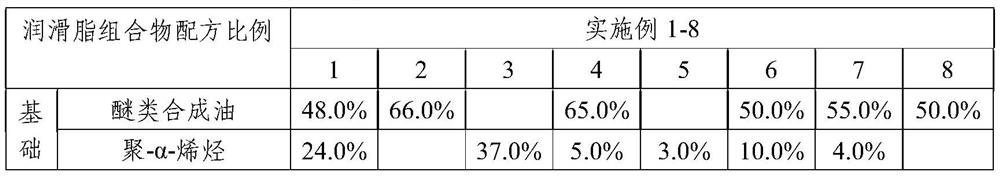

[0028] The grease preparation method was the same as in Example 1, except that the formula ratio of the grease composition in each embodiment was different, see Table 1 for details.

[0029] Table 1 embodiment grease composition proportioning

[0030]

[0031]

experiment example 1

[0033] This experimental example evaluates the comprehensive performance of the conductive bearing grease composition in Examples 1-8 of the present invention, and the test results are shown in Table 2.

[0034] The anti-wear performance adopts the four-ball machine method, the test method is SH / T 0204, the speed is 1200rpm, the temperature is 75°C, and the test time is 30 minutes. After the test is completed, measure the average wear scar diameter of the three balls below. The smaller the wear scar, the grease is more resistant to wear The better the performance; in the machinery industry, according to JB / T5414 (measurement method of vibration acceleration of rolling bearings), the vibration noise of bearings is divided into Z1 / Z2 / Z3 / Z4 groups, and each level has a difference of 4 decibels (dB). Under the specified test conditions, the noise performance of the grease is tested on the S0910 acceleration type vibration instrument; the pressurized differential thermal analysis PD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com