Manufacturing method of antioxidant high-strength duplex stainless steel pipe

A technology of duplex stainless steel and a manufacturing method, applied in the field of stainless steel pipe processing, can solve the problems of resistance to sales and promotion of stainless steel pipes, narrow the application range of stainless steel pipes, shorten the service life of stainless steel pipes, etc. The effect of improving antioxidant strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

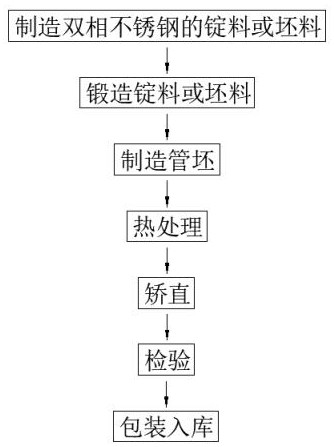

[0026] see figure 1 , the present invention provides a technical solution: a method for manufacturing an anti-oxidation high-strength duplex stainless steel tube, the method for manufacturing a high-strength duplex stainless steel tube with oxidation resistance includes the following preparation steps: manufacturing an ingot or billet of duplex stainless steel - a forging ingot Raw material or blank - making tube blank - heat treatment - straightening - inspection - packaging and storage, the chemical composition and mass percentage of this anti-oxidation high-strength duplex stainless steel tube are: C: 0.03%, Mn: 1.7%, Si: 0.6% , P: 0.01%, S: 0.022%, Cr: 16.0%, Ni: 4.0%, Mo: 3.0%, N: 0.1%, the balance is Fe and inevitable impurity elements;

[0027] The process of manufacturing duplex stainless steel ingots or billets: place the metal iron in an electric arc furnace, melt it to obtain blast furnace molten iron, put the alloy into an intermediate frequency furnace to obtain a...

Embodiment 2

[0034] see figure 1 , The present invention provides a technical solution: a method for manufacturing an anti-oxidation high-strength duplex stainless steel tube, the method for manufacturing an anti-oxidative high-strength duplex stainless steel tube includes the following preparation steps: manufacturing an ingot or billet of duplex stainless steel - a forging ingot Raw material or blank - manufacturing tube blank - heat treatment - straightening - inspection - packaging and storage, the chemical composition and mass percentage of the oxidation-resistant high-strength duplex stainless steel tube are: C: 0.04%, Mn: 1.8%, Si: 0.8% , P: 0.02%, S: 0.026%, Cr: 19.0%, Ni: 5.0%, Mo: 4.0%, N: 0.12%, the balance is Fe and inevitable impurity elements;

[0035]The process of manufacturing duplex stainless steel ingots or billets: place the metal iron in an electric arc furnace, melt it to obtain blast furnace molten iron, put the alloy into an intermediate frequency furnace to obtain ...

Embodiment 3

[0042] see figure 1 , the present invention provides a technical solution: a method for manufacturing an anti-oxidation high-strength duplex stainless steel tube, the method for manufacturing a high-strength duplex stainless steel tube with oxidation resistance includes the following preparation steps: manufacturing an ingot or billet of duplex stainless steel - a forging ingot Raw material or blank - making tube blank - heat treatment - straightening - inspection - packaging and storage, the chemical composition and mass percentage of the oxidation-resistant high-strength duplex stainless steel tube are: C: 0.06%, Mn: 2.0%, Si: 0.9% , P: 0.03%, S: 0.030%, Cr: 23.0%, Ni: 7.0%, Mo: 5.0%, N: 0.14%, the balance is Fe and inevitable impurity elements;

[0043] The process of manufacturing duplex stainless steel ingots or billets: place the metal iron in an electric arc furnace, melt it to obtain blast furnace molten iron, put the alloy into an intermediate frequency furnace to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com