Material collecting yarn guiding device of twisting machine

A twisting machine and wire technology, which is applied in the field of twisting machine receiving wire device, can solve the problems that the yarn receiving quality cannot be guaranteed and cannot be replaced separately, so as to prolong the service life, reduce production costs, and improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

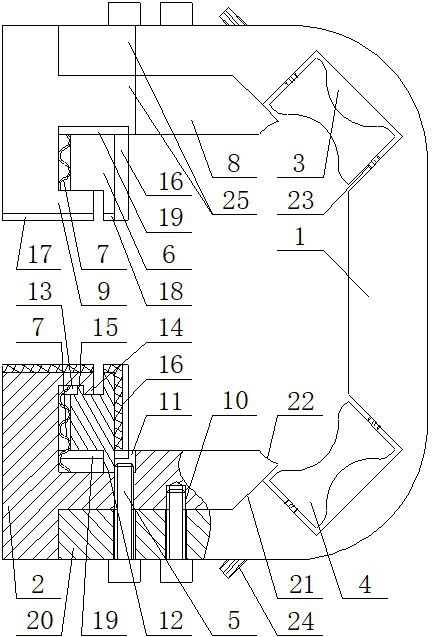

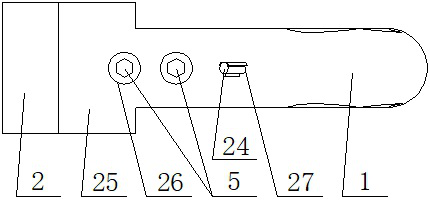

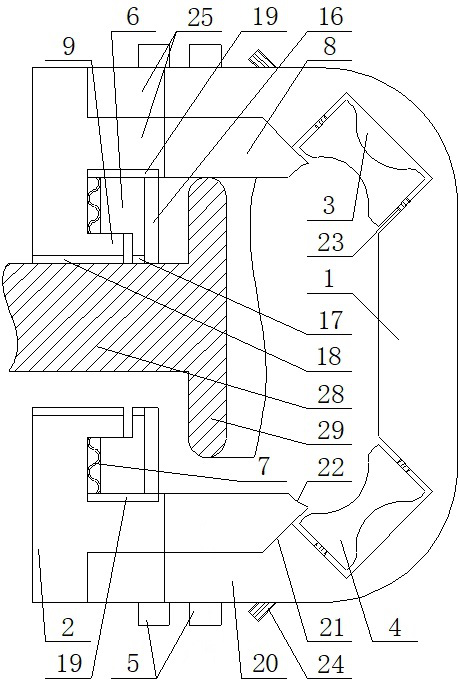

[0033] combine Figure 1~Figure 7 It can be seen that the twisting machine receiving wire device of the present invention includes a "匚" type frame rod 1, and the "匚" type frame rod 1 is located inside the annular retaining ring 29, and the annular retaining ring 29 is connected with the receiving wire of the twisting machine. The material rotating rod moves relative to the axial direction. The end rods 20 on both sides of the "匚" type frame rod 1 are parallel to each other and are respectively located at the two ends of the annular retaining ring 29. The middle part of the outer wall of the annular retaining ring 29 is connected by The plate 28 is connected with the twisting machine, the connecting plate 28 is perpendicular to the axial center of the annular retaining ring 29, and the end rods 20 are respectively detachably and symmetrically fixed with clamping rods 2, and the clamping rods 2 are positioned at the center of the annular retaining ring 29. Outside, and perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com