Anti-erosion hydraulic fracturing spraying device and fracturing method

A technology of hydraulic fracturing and injection devices, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., which can solve problems such as cost increase, coiled tubing erosion, and restricted application, so as to eliminate erosion and improve Protective effect, anti-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

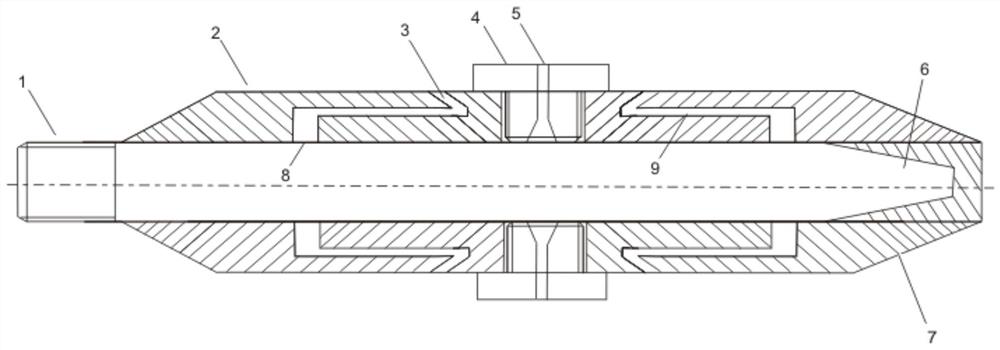

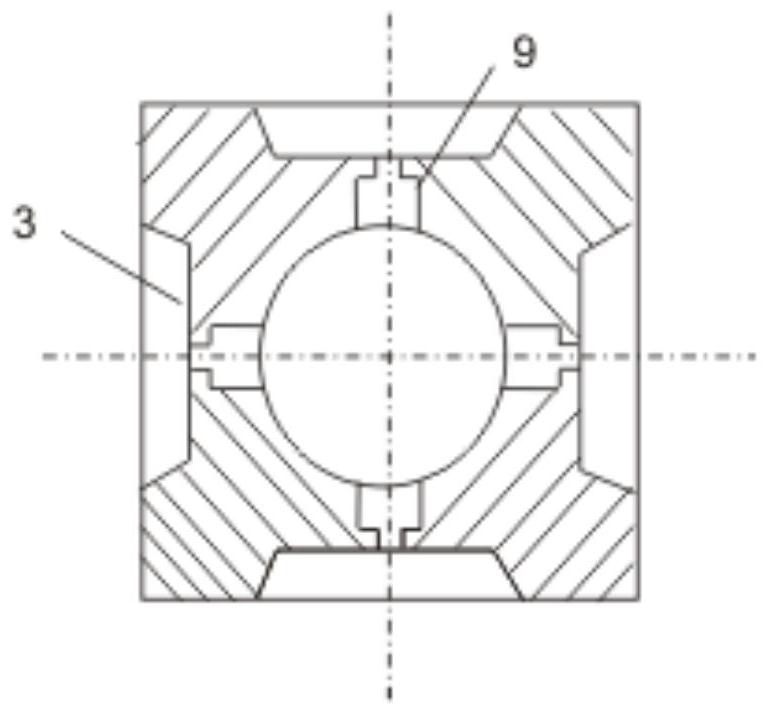

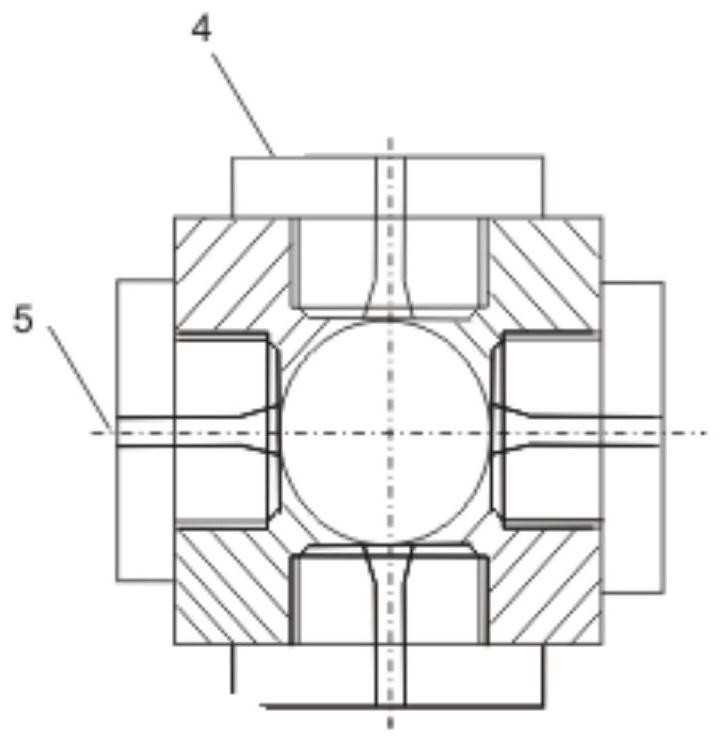

Embodiment 1

[0045] The length of the horizontal section of well A2 in He 8 section of an oilfield is 765m, and the well depth is 6500m. The designed fracturing section is 4 sections, each section has 6 clusters, the cluster spacing is 25m, and the designed sand mixing fluid volume of each section is 45m 3 , fracturing fluid 3000m 3 , the proppant chooses ceramsite of 30-50 mesh, and the designed sand addition amount of the proppant is 500m 3 . The size of the new anti-erosion hydraulic fracturing injection device selected according to the diameter of the downhole oil pipe is: the diameter of the injector joint is 121.11mm; the length of the spray gun is 550mm, the height is 200mm, and the width is 200mm; the width of the protective nozzle is 2mm; the diameter of the fracturing nozzle is 150mm; the diameter of the fracturing nozzle is 6mm; the depth of the reflux tank is 120mm; the length of the guide head is 120mm; the diameter of the inlet section of the flow channel of the protective n...

Embodiment 2

[0054] The length of the horizontal section of Well A32 in the Hechuan section of Yanchang Oilfield is 900m, and the well depth is 4500m. The designed fracturing section is 6 sections, each section has 4 clusters, the cluster spacing is 20m, and the designed sand mixing fluid volume of each section is 35m 3 , fracturing fluid 5000m 3 , the proppant chooses 50-100 mesh ceramsite, and the designed sand addition amount of the proppant is 1000m 3 . The size of the new anti-erosion hydraulic fracturing injection device selected according to the diameter of the downhole tubing is: the diameter of the injector joint is 168.14mm; the length of the spray gun is 550mm, the height is 240mm, and the width is 240mm; the width of the protective nozzle is 3mm; the diameter of the fracturing nozzle is 200mm; the diameter of the fracturing nozzle is 8mm; the depth of the reflux tank is 150mm; the length of the guide head is 130mm; the diameter of the inlet section of the flow channel of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com