Inverted siphon engineering construction method

A technology for engineering construction and reverse siphoning, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of difficult-to-clean methods, collection of sewage, cross-flow of sewage, etc., to increase the cleaning cycle time, reduce processing difficulty, and reduce redundant Effects of remaining parts and volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

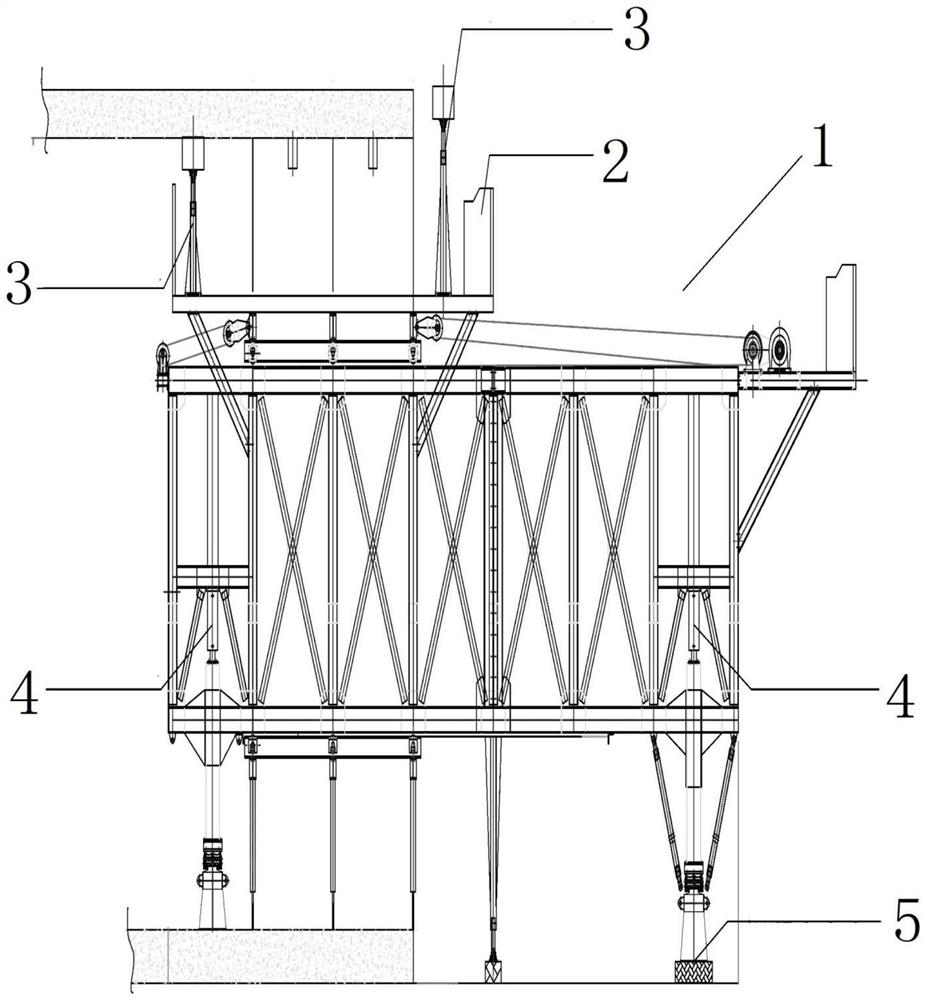

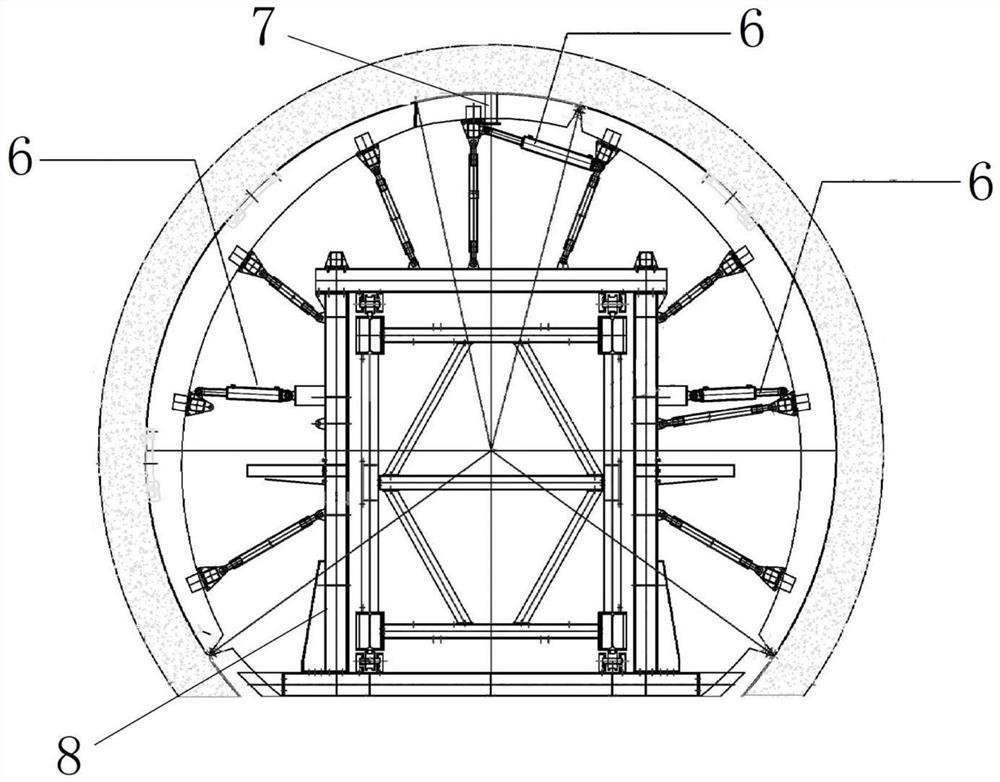

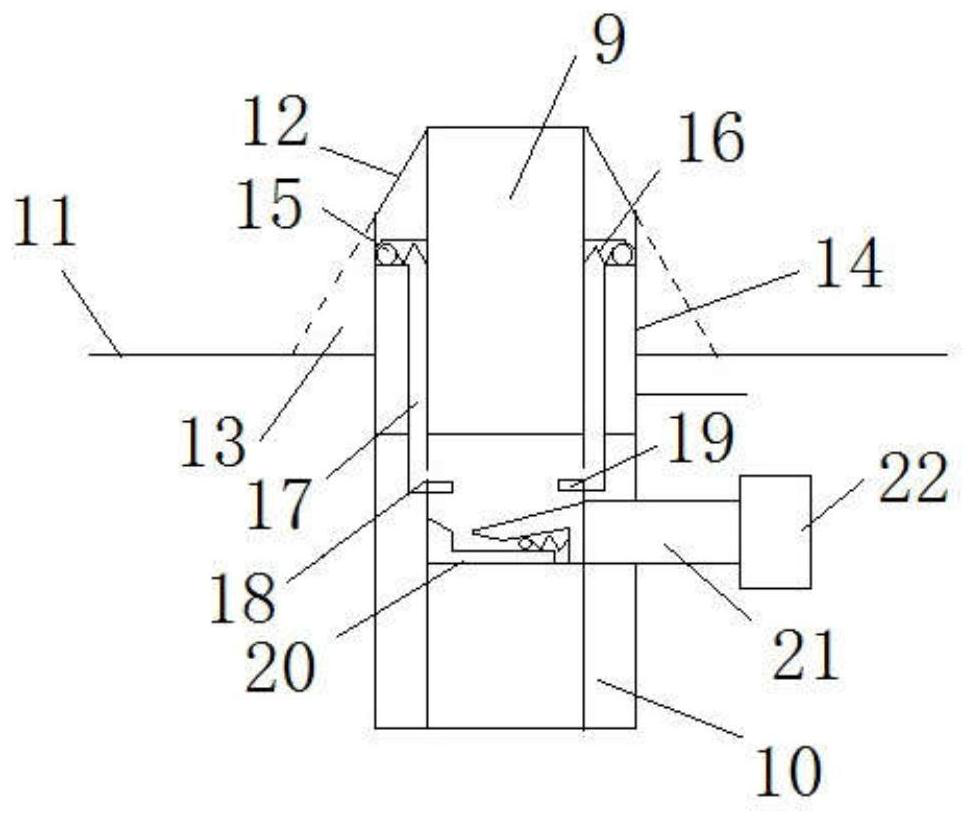

[0053] As shown in the figure: a construction method of an inverted siphon engineering, constructing an inverted siphon tunnel, the construction method includes a tunnel excavation method, a lining pouring method, and a ventilation method; the tunnel includes an exit pool, an entrance pool, and a horizontal section , Inclined pipe section; the ventilating method includes the drill rig drilling downwards above the tunnel to connect the tunnel with the outside world; performing air replenishment and exhaust to avoid undesirable working conditions such as negative pressure.

[0054] The tunnel excavation method includes: an excavation method and a blasting method; the excavation method includes first excavating the outlet pool hole, then excavating the inclined pipe section and the horizontal section, and finally excavating the inlet pool hole; Blast the tunnel before digging, the blasting steps are as follows:

[0055] Step 1, first excavating a pilot tunnel to ascertain the geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com