Scroll compressor

A scroll compressor and moving scroll technology, applied in the field of compressors, can solve problems such as difficulty in starting the scroll compressor, large starting torque, and affecting the normal operation of the compressor, so as to improve the start-up performance, improve the compression effect, Increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

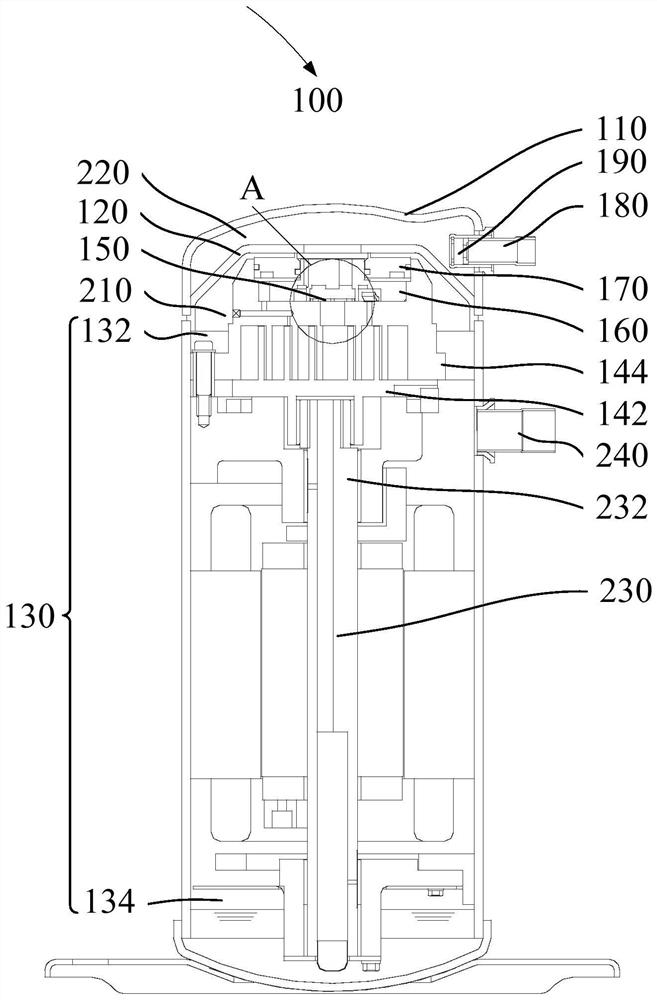

[0049] like figure 1 As shown, according to some embodiments of the present invention, one embodiment of the present invention provides a scroll compressor 100, the scroll compressor 100 includes: casing 110, isolation plate 120, frame 130, movable scroll Disk 142 and fixed scroll 144 .

[0050] Wherein, the casing 110 defines the inner space of the scroll compressor 100 , and an isolation plate 120 is arranged inside the casing 110 , and the inner space of the scroll compressor 100 is divided into a suction space 210 and a discharge space 220 by the isolation plate 120 . The suction space 210 is used to accommodate uncompressed refrigerant, and the discharge space 220 is used to accommodate compressed refrigerant.

[0051] The movable scroll 142 and the fixed scroll 144 are cooperatively arranged in the suction space 210 . The movable scroll 142 and the fixed scroll 144 may cooperate to form: a suction chamber 250 , an intermediate pressure chamber 260 and a discharge chamb...

Embodiment 2

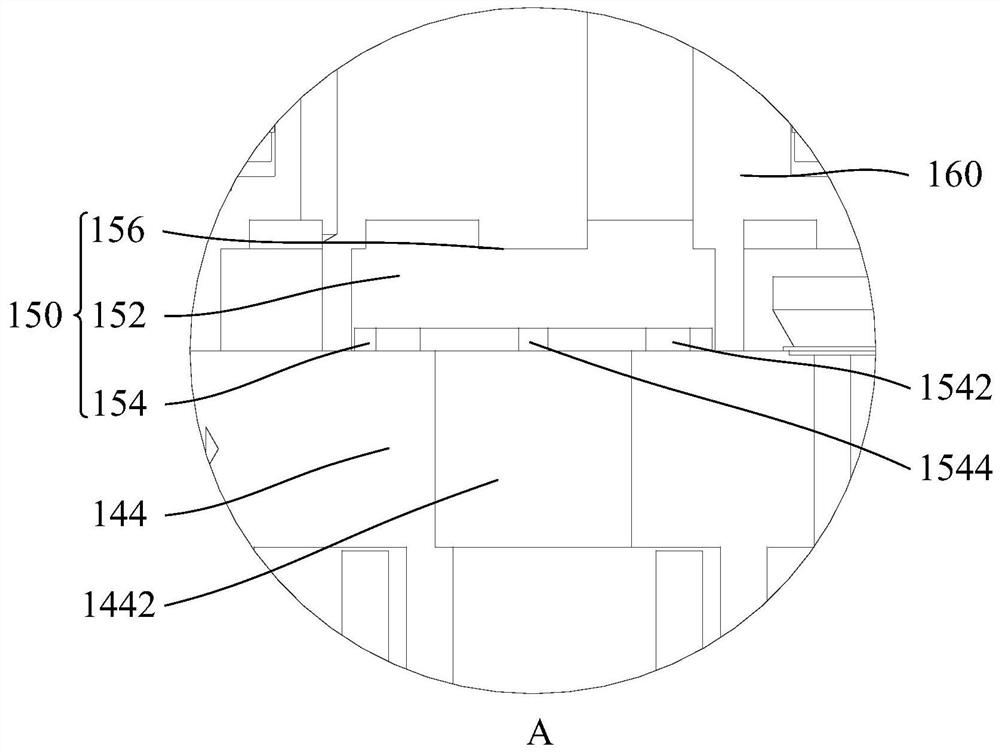

[0056] like Figure 2 to Figure 4 As shown, on the basis of Embodiment 1, further, the pressure relief low return structure 150 includes: a first slideway 152 and a pressure relief low return plate 154 that can slide in the first slideway 152 .

[0057] Specifically, when the movable scroll 142 and the fixed scroll 144 discharge the refrigerant, the pressure relief low return plate 154 is pushed by the refrigerant and moves away from the fixed scroll 144 . At this time, a larger passing area is maintained between the second through hole 1442 and the third through hole 1542 , so that a large amount of refrigerant can quickly enter the discharge space 220 from the second through hole 1442 through the third through hole 1542 .

[0058] And when the movable scroll 142 and the fixed scroll 144 discharge the refrigerant, since the pressure in the discharge space 220 is greater than the pressure between the movable scroll 142 and the fixed scroll 144, specifically, the pressure in th...

Embodiment 3

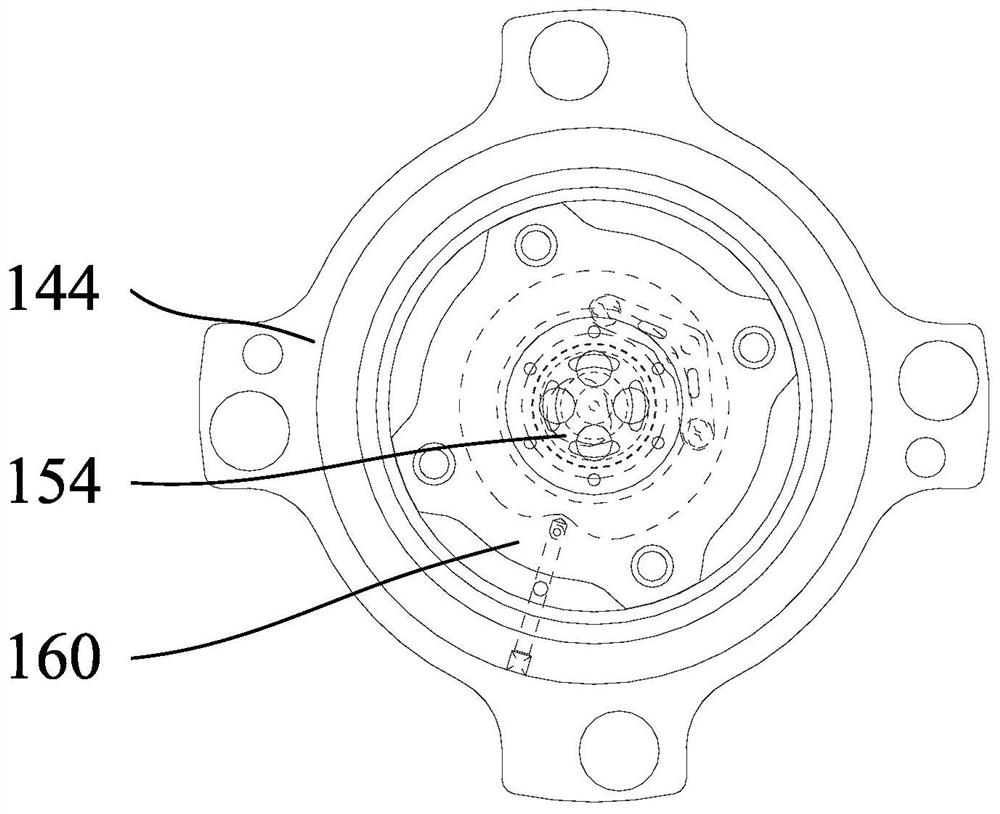

[0063] like Figure 5 As shown, on the basis of Embodiment 1 or Embodiment 2, further, there are multiple passages on the pressure relief low return plate 154 . When the pressure relief low return plate 154 is against the fixed scroll 144, part of the passage can be blocked.

[0064] Specifically, a hole is opened on the pressure relief low return plate 154, and the hole includes a third through hole 1542 and a fourth through hole 1544. When the pressure relief low return plate 154 and the fixed scroll 144 are in contact, the fixed scroll 144 can be blocked. In the third through hole 1542 , only the fourth through hole communicates with the second through hole 1442 and the third through hole 1542 .

[0065] Further, the cross-sectional area of the pressure relief low back plate 154 is greater than the cross-sectional area of the second through hole 1442 . That is, the pressure relief low return plate 154 can be set on the edge of the second through hole 1442 , and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com