Garbage pyrolyzing furnace and method for treating garbage by using garbage pyrolyzing furnace

A pyrolysis furnace and waste technology, which is applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of incomplete waste treatment, and the exhaust gas cannot meet the environmental protection emission requirements, and achieve the effect of ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

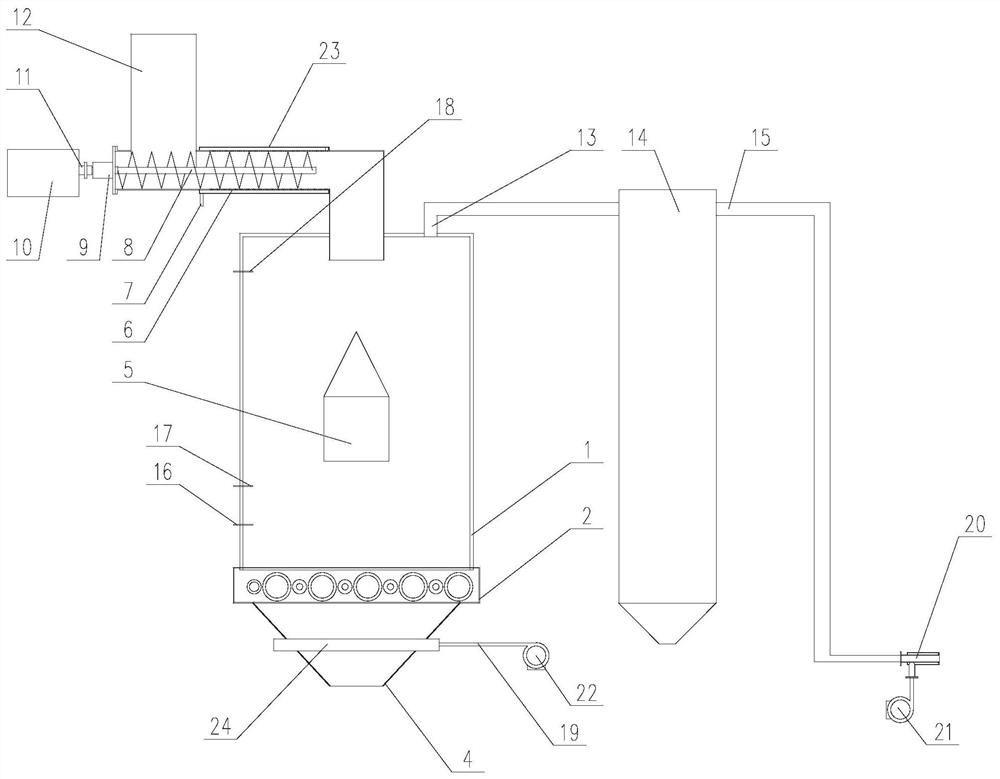

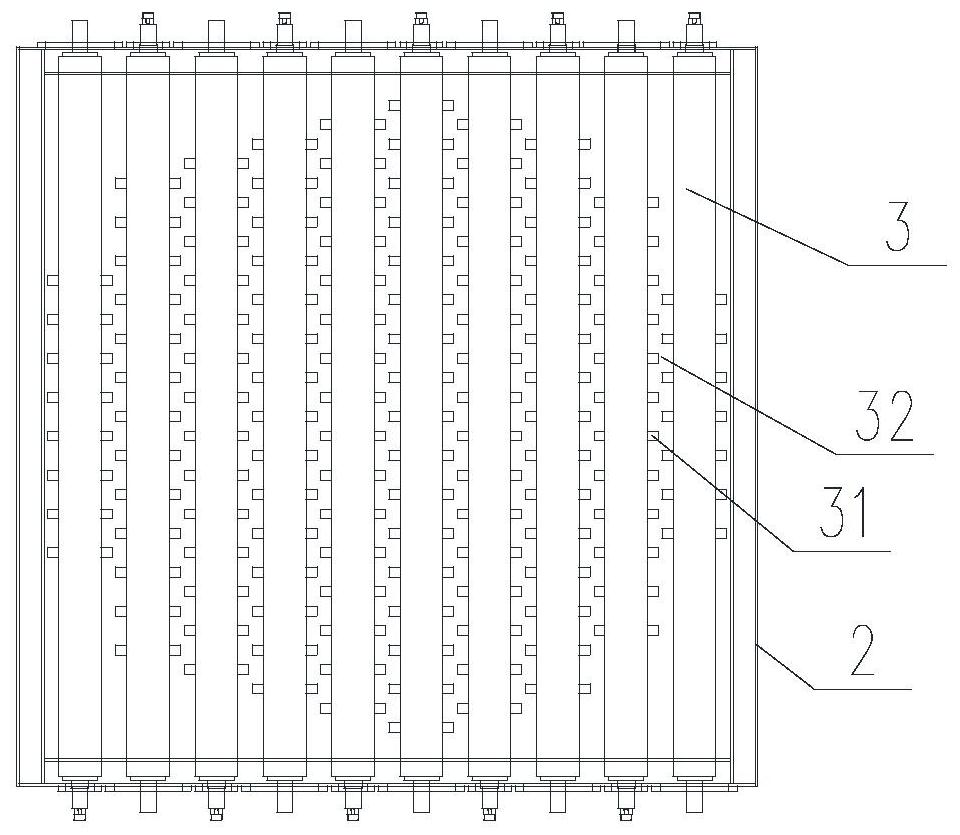

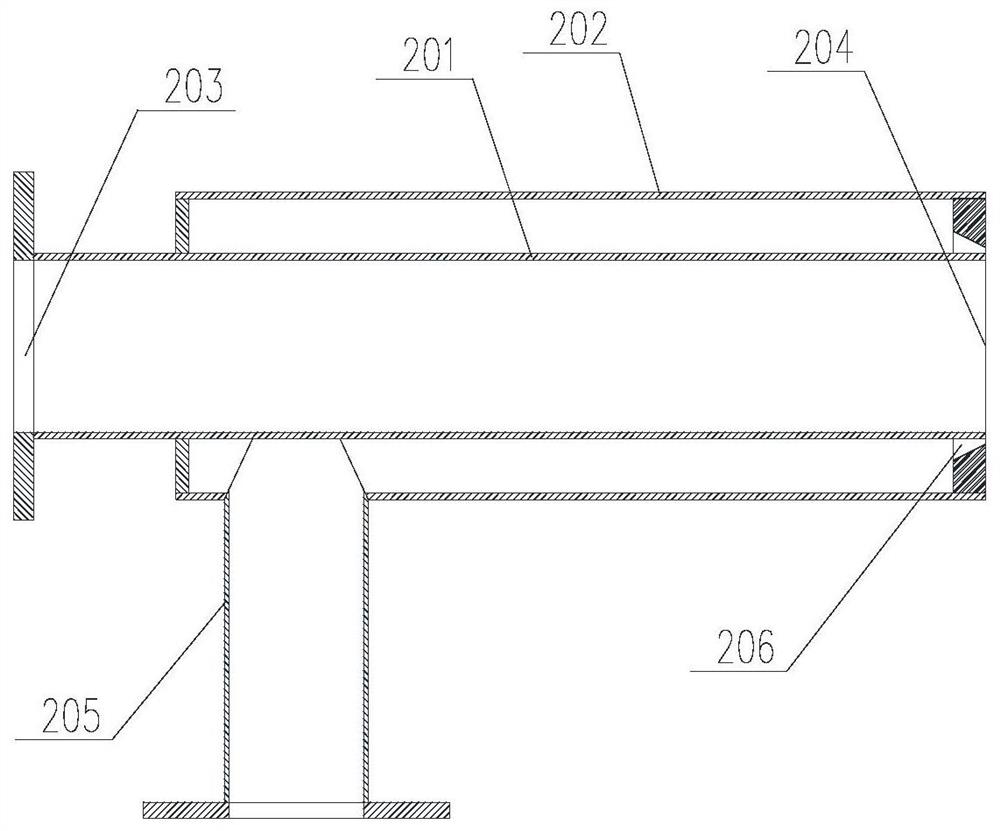

[0031] Such as Figure 1-Figure 4 As shown, a garbage pyrolysis furnace includes a furnace body 1, the inside of the furnace body 1 is provided with a distributor 5, and the inner side wall of the furnace body 1 is provided with a gas chamber thermocouple 18 near the top. 1 The inner side wall near the bottom is provided with a gasification layer thermocouple 17 and a high temperature layer thermocouple 16 in sequence from top to bottom, and the top of the furnace body 1 is provided with a feed pipe 6 communicating with its interior, and the feed pipe 6 The end far away from the furnace body 1 is connected with the electric drive device 10 through the bearing box 9 and the shaft coupling 11 in turn, and the end of the top of the feeding pipe 6 close to the bearing box 9 is provided with a material storage box 12 communicating with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com