Concrete surface strain sensor with high output sensitivity and manufacturing and measuring method thereof

A concrete surface and strain sensor technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problem that the sensitivity cannot meet the needs of use, and achieve the effect of optimizing output sensitivity, ensuring stability, and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

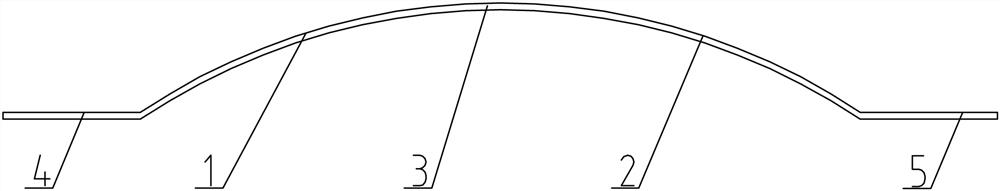

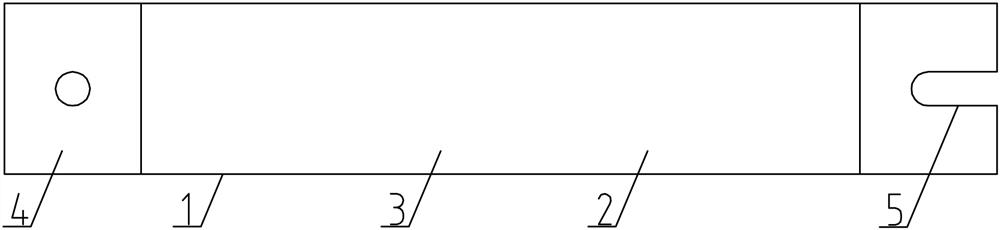

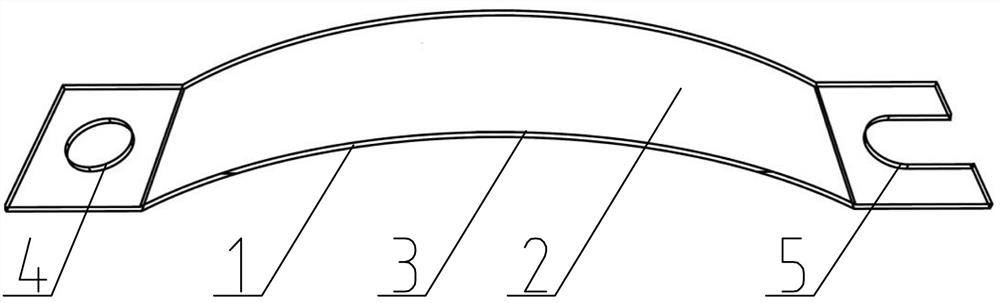

[0045] see Figure 1-6 , a concrete surface strain sensor with high output sensitivity, which includes an elastic element 1, and a strain gauge circuit structure 3 for collecting and converting strain signals is arranged on the vault of the elastic element 1, and the strain gauge circuit structure 3 passes through The waterproof layer structure 2 is packaged and bonded on the top of the elastic element 1, and the two arches of the elastic element 1 are respectively provided with a fixed hinge support 4 and a movable hinge support 5.

[0046] Further, the vault strain of the elastic element 1 has nothing to do with the material, and it is made of galvanized iron sheet material. Make sure it has some flexibility.

[0047] Further, in order to make the strain response of the vault sufficiently sensitive, the elastic element 1 is optimized during the preparation process of the elastic element 1, and the sensing efficiency of the arch elastic element 1 with different sizes is solv...

Embodiment 2

[0054] The manufacturing method of the concrete surface strain sensor with high output sensitivity comprises the following steps:

[0055] Step 1: Grinding the vault of the elastic element 1 so as to level the first strain gauge 6, the second strain gauge 7, the third strain gauge 8 and the fourth strain gauge 9 to be pasted;

[0056] Step 2: Use the quick-drying adhesive base layer 14 to perform preliminary waterproof glue treatment on the bottom layer, and then use the quick-drying adhesive base layer 14 to paste the first strain gauge 6, the second strain gauge 7, the third strain gauge 8 and the fourth strain gauge 9 at the vault;

[0057] Step 3: After pasting all the strain gauges, use adhesive tape to wrap several circles of tape on the end of the strain gauge wires to prevent short circuits between the strain gauges and the elastic elements;

[0058] Step 4: Solder the wires of the strain gauge with tin and the external wires, and connect them according to the full br...

Embodiment 3

[0063] The method for measuring the concrete surface strain sensor with high output sensitivity comprises the following steps:

[0064] The average strain between the supports is represented by the strain generated by the support displacement of the concrete surface strain sensor on the vault. In the calculation equation, ε is the strain on the concrete surface, ε 读 is the reading of the sensor, S is the output sensitivity of the sensor, Δ 支座反力 is the displacement generated by the reaction force of the support at the bonding point, and L is the span of the sensor. The calculation equation is as follows:

[0065]

[0066] In order to reduce the error of the bonding point of the support, the influence of the bonding point during work is studied. A 2mm gasket is used at the support, and its area S 垫片 =3.14mm 2 , consider the displacement generated by the support reaction force to calculate, where τ 支座 is the shear stress at the support, F 支座反力 is the reaction force at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com