Patents

Literature

57results about How to "Improve output sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

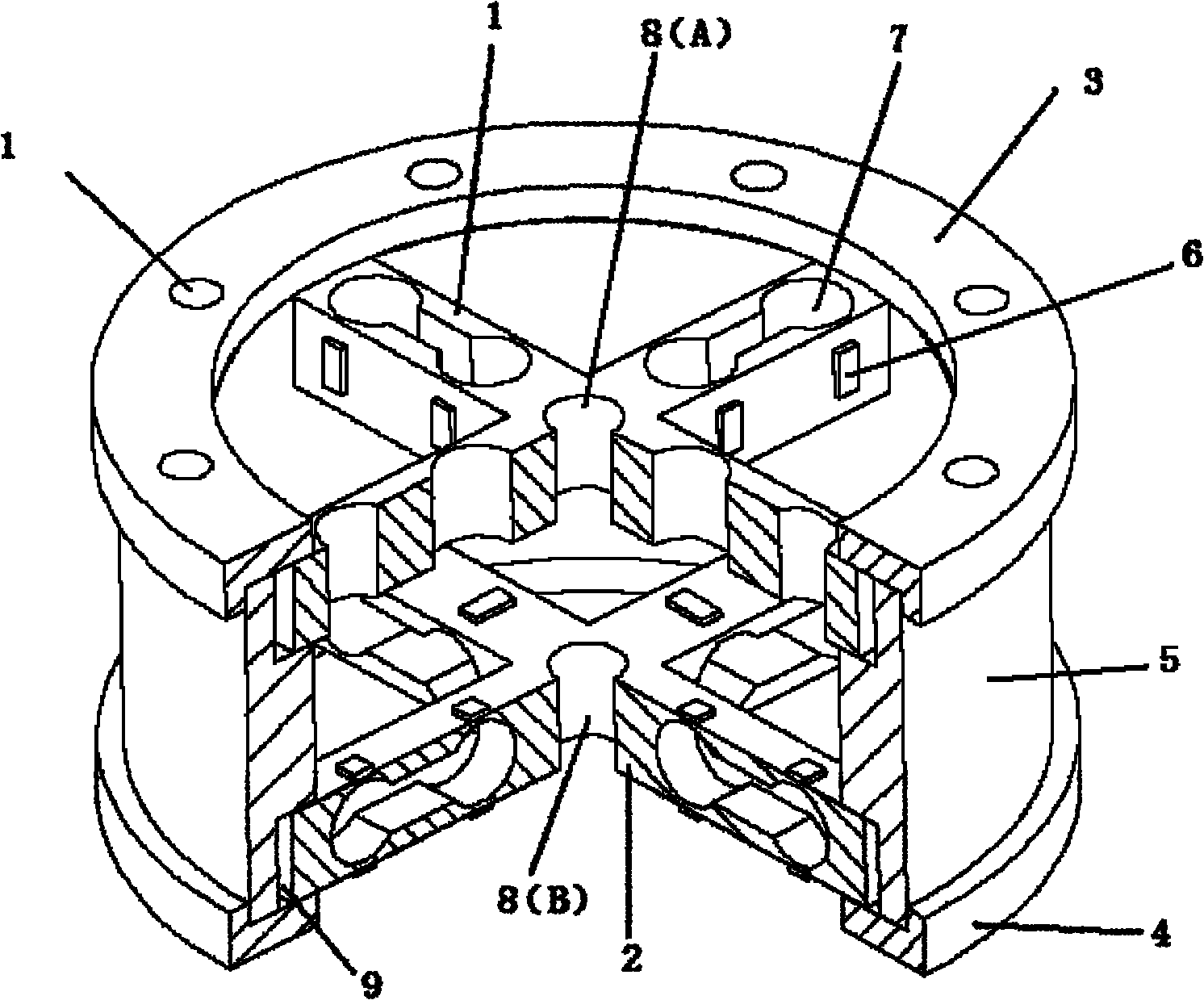

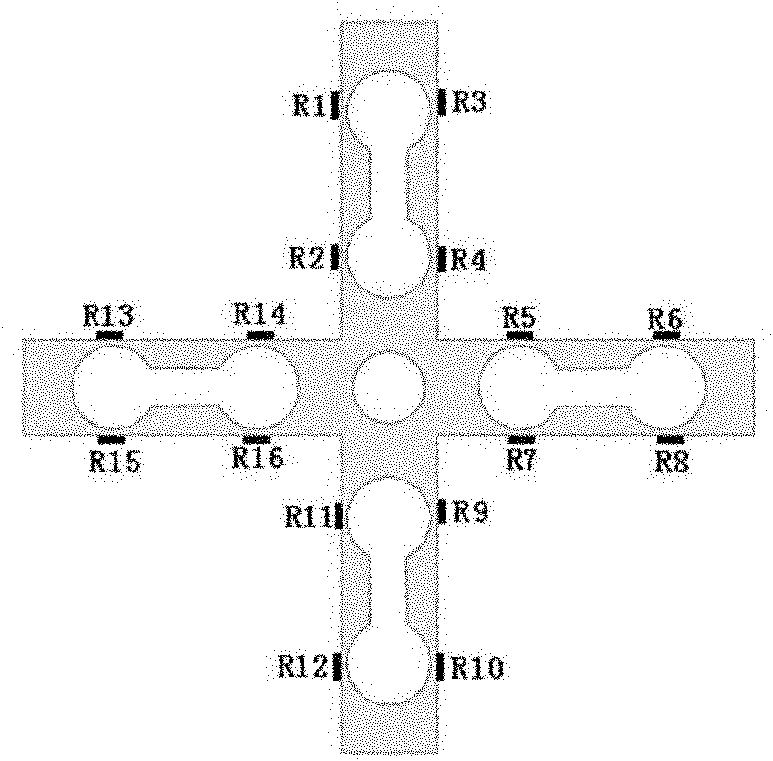

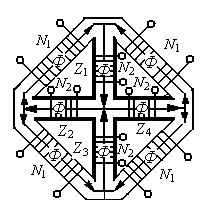

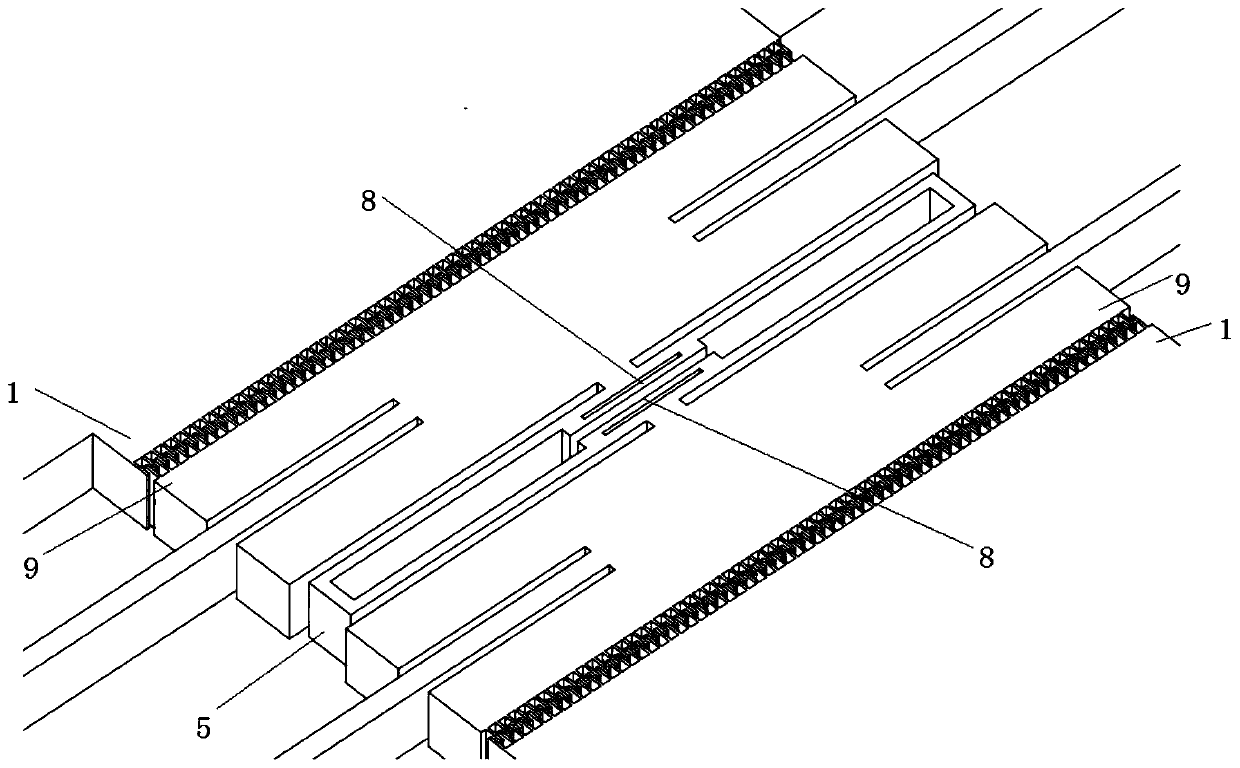

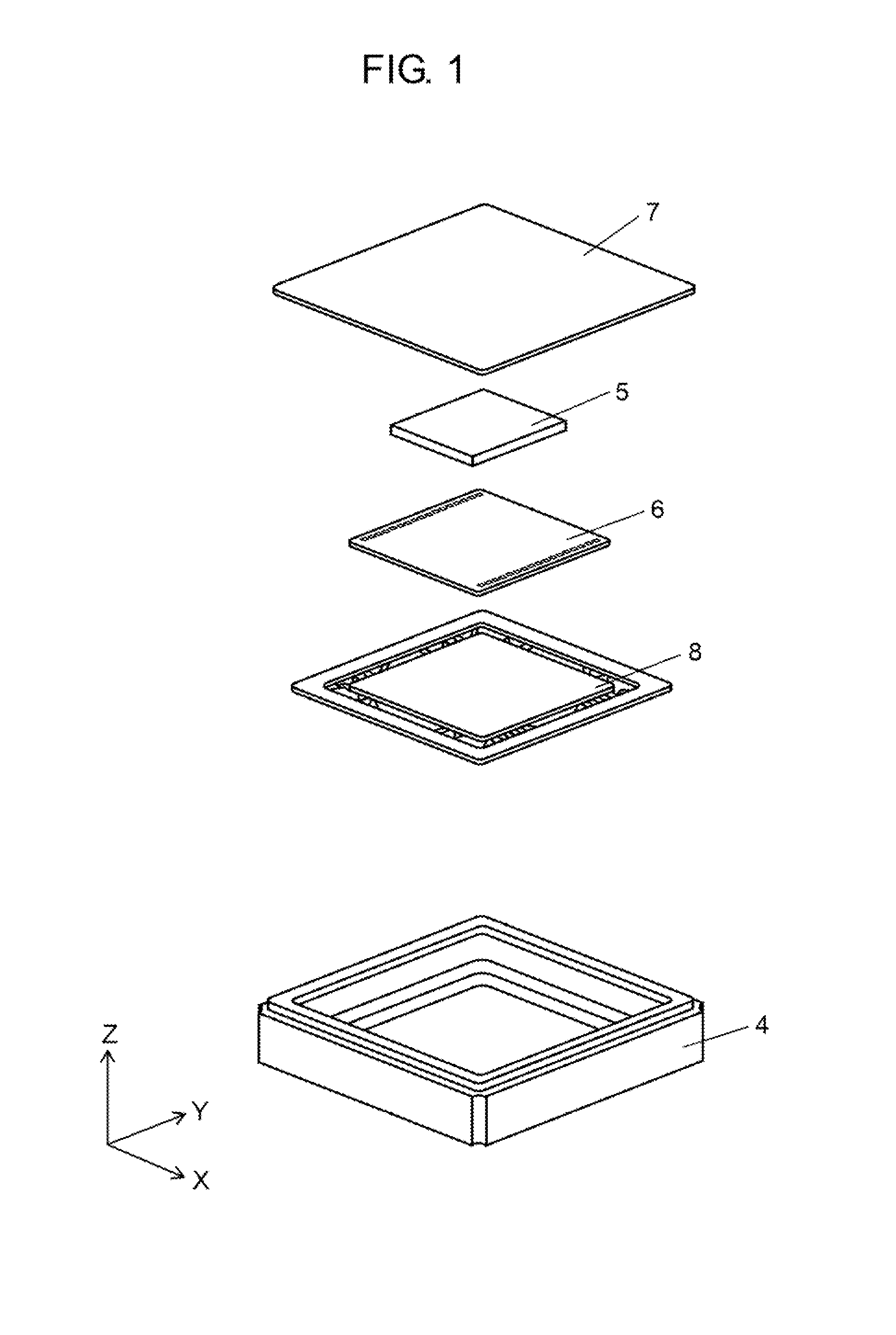

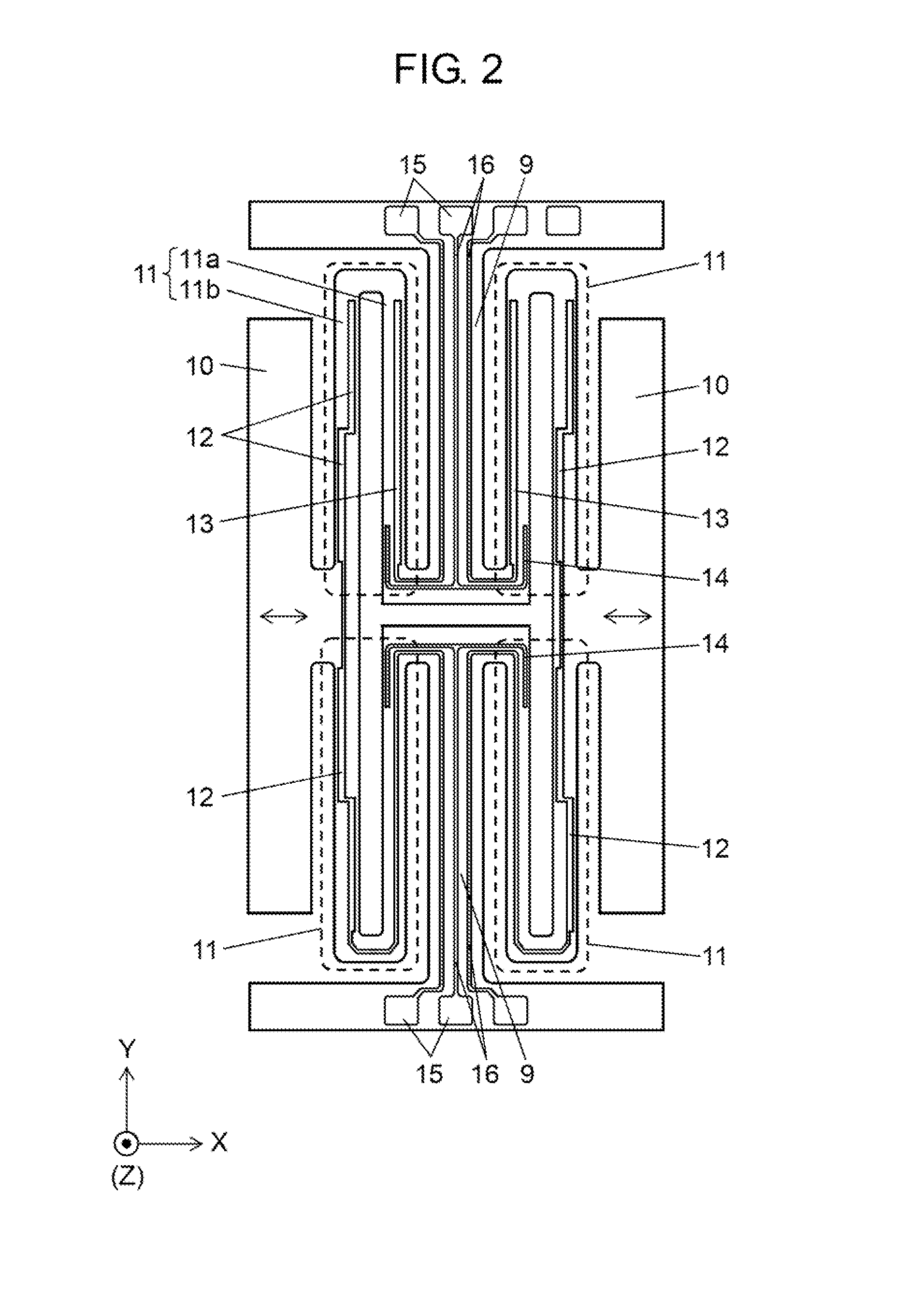

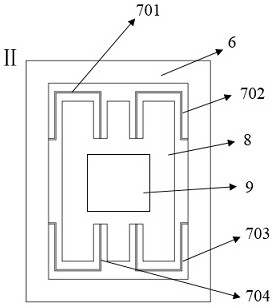

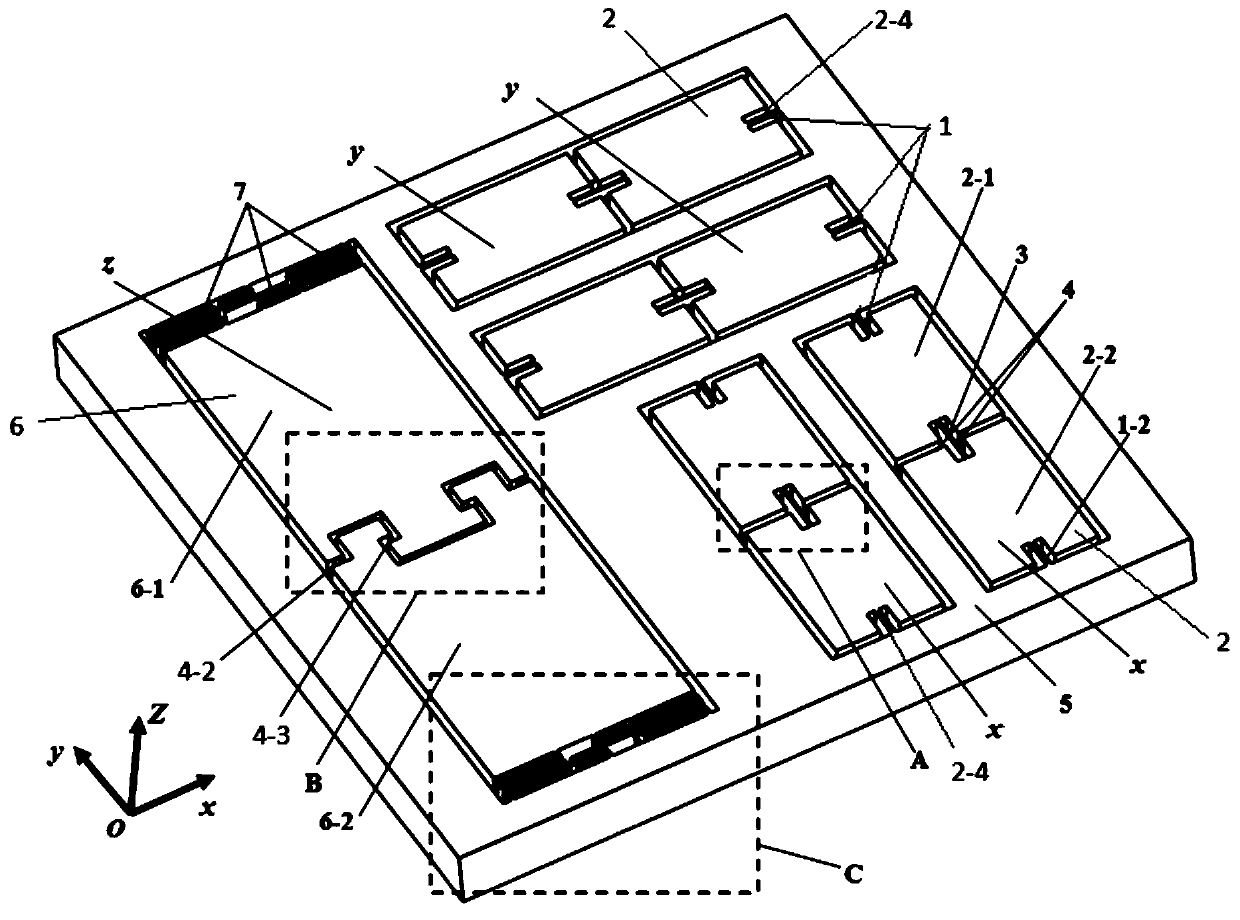

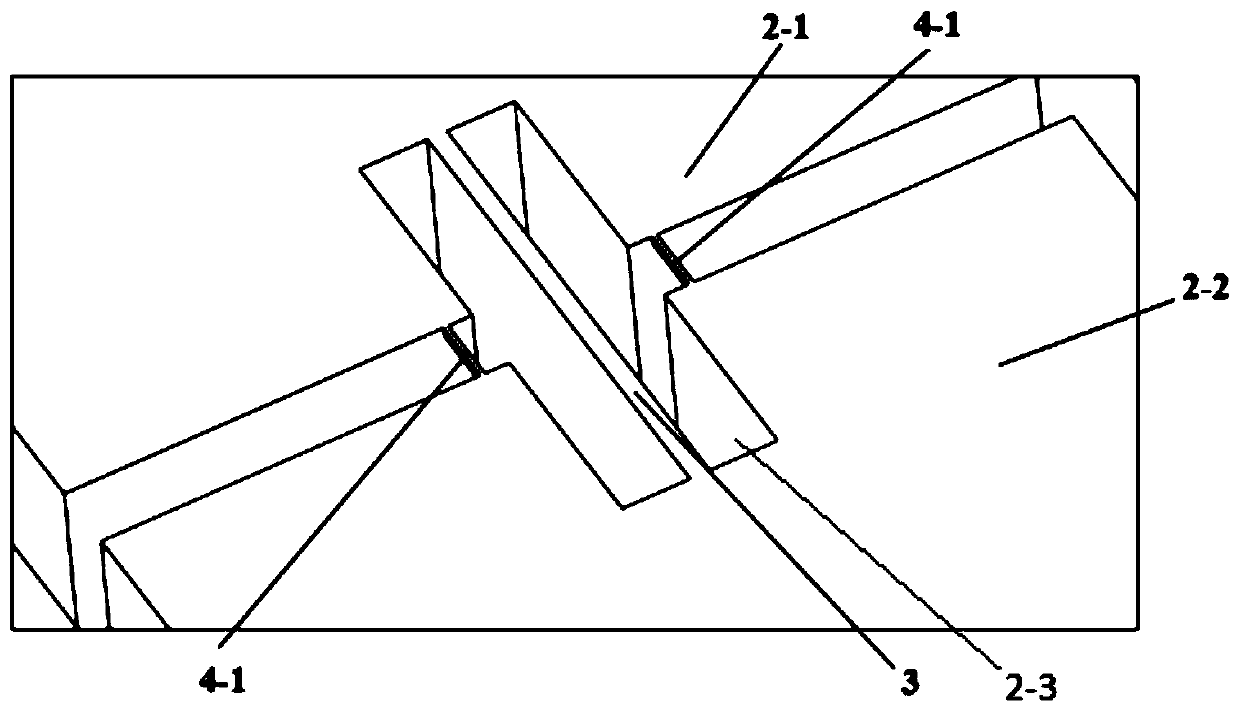

Double rood beam high-sensitivity six-dimensional moment sensor

ActiveCN102095534AImprove output sensitivityForce measurementWork measurementCouplingClassical mechanics

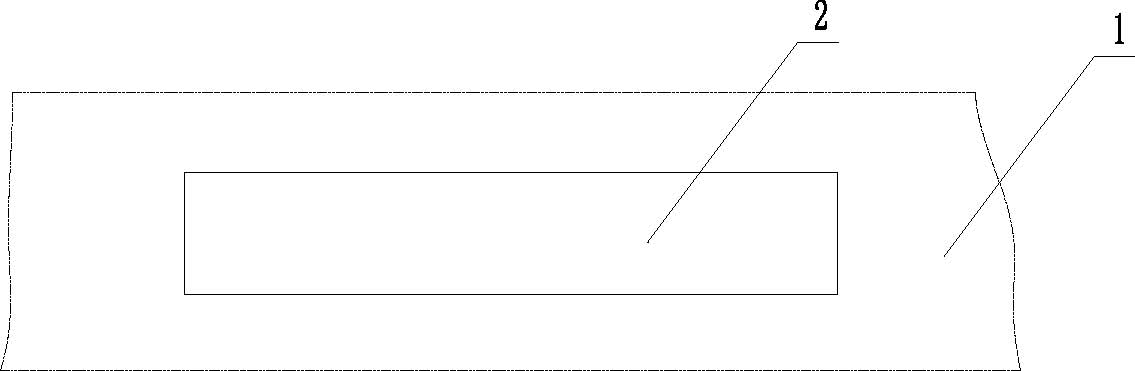

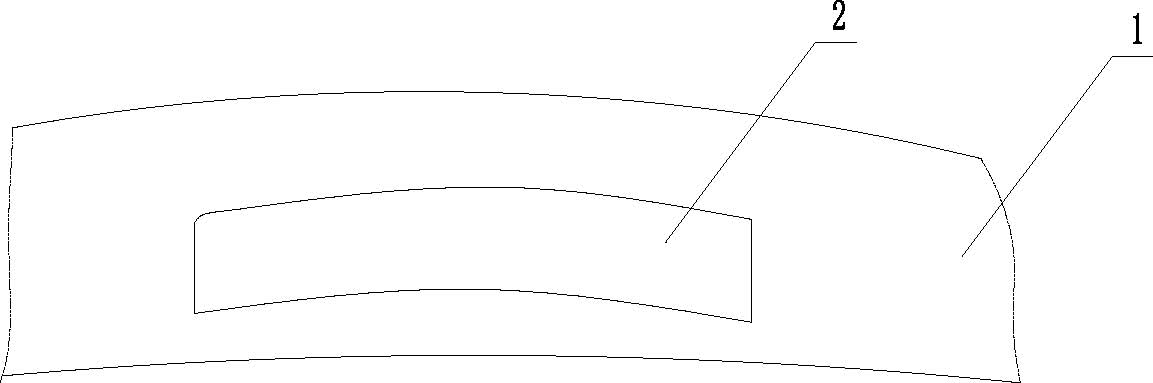

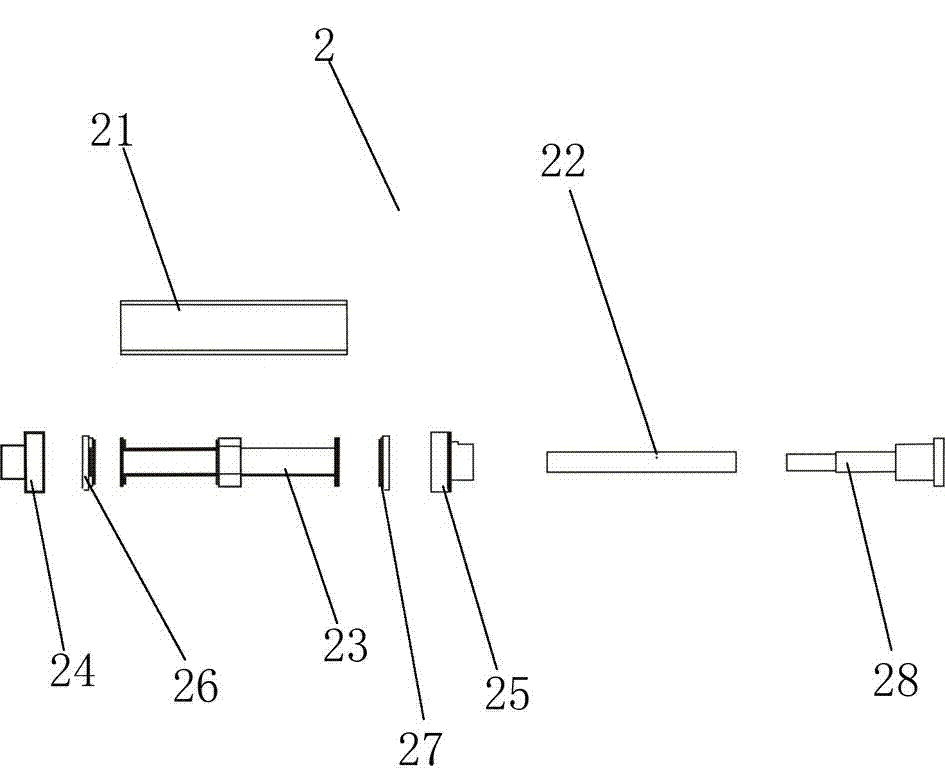

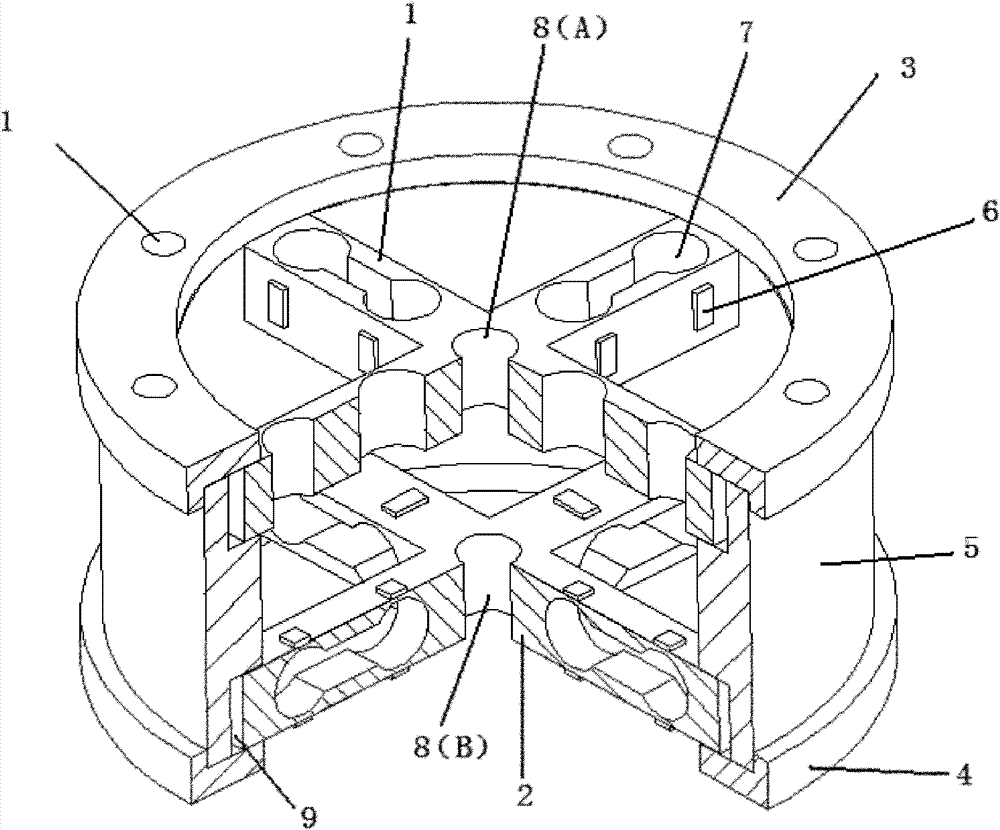

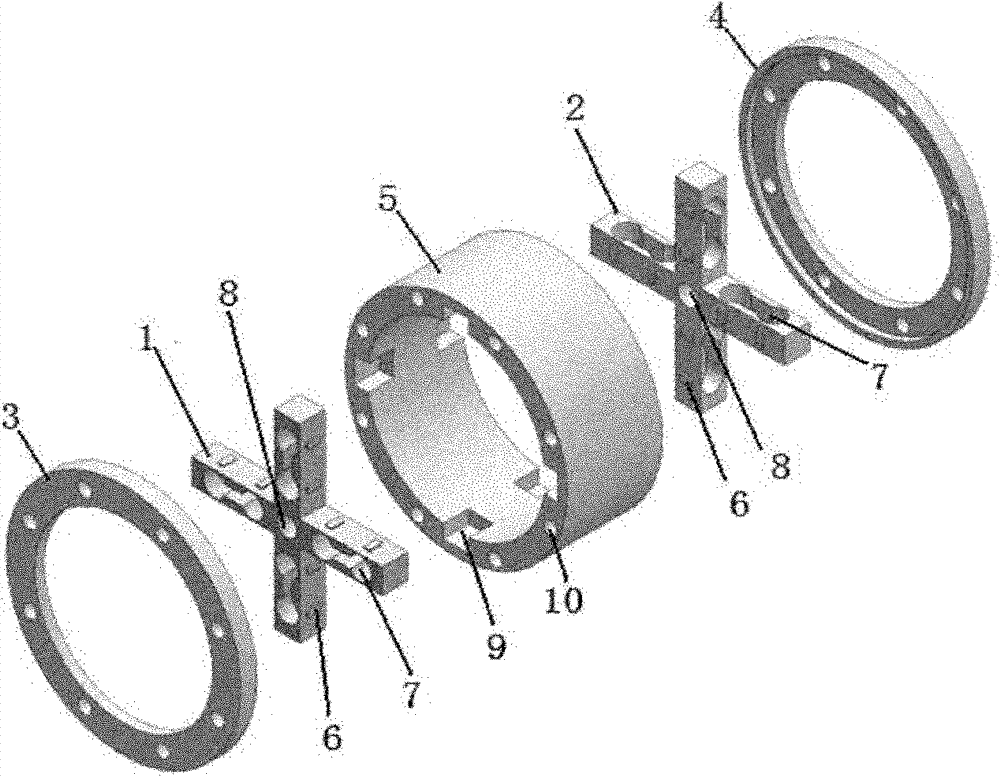

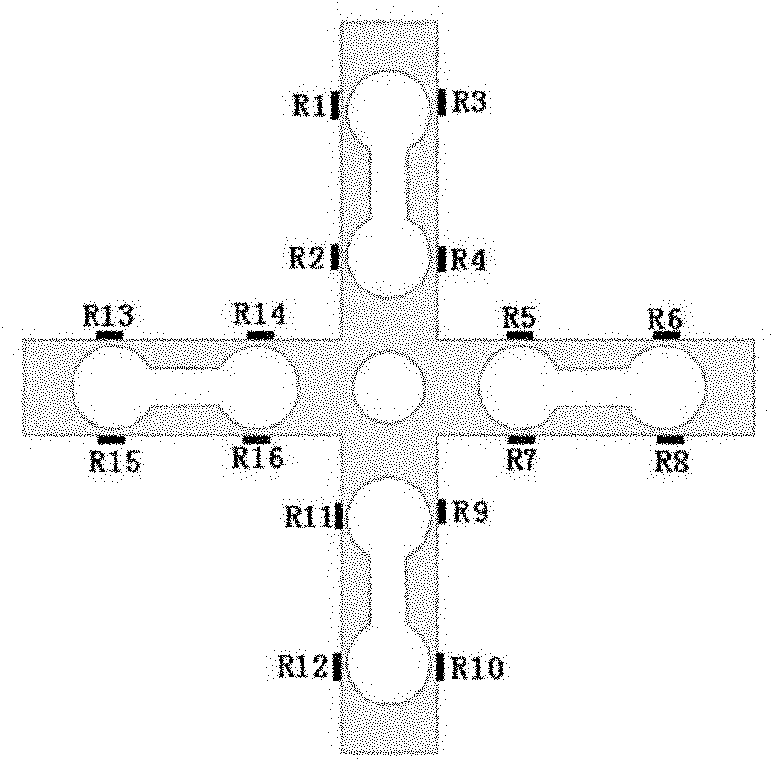

The invention discloses a double rood beam high-sensitivity six-dimensional moment sensor in the technical field of robots. The double rood beam high-sensitivity six-dimensional moment sensor comprises two rood beams, two dead rings, one outer ring, and a plurality of resistance strain gages; a first rood beam and a second rood beam are arranged outside the outer ring respectively and are used as elastic bodies of the sensor for sensing stress; two dead rings are arranged outside the first rood beam and the second rood beam respectively; the resistance strain gages are adhered to the rood beams; each of the rood beams consists of four identical double-hole parallel sub beams; each double-hole parallel sub beam is provided with an I-shaped through hole; and a center hole is formed in the geometric center of each rood beam. In the double rood beam high-sensitivity six-dimensional moment sensor, floating beams used by the conventional six-dimensional moment sensor and crosstalk caused by the floating beams are removed, multi-component coupling is reduced conveniently and the measurement accuracy is improved.

Owner:SHANGHAI JIAO TONG UNIV

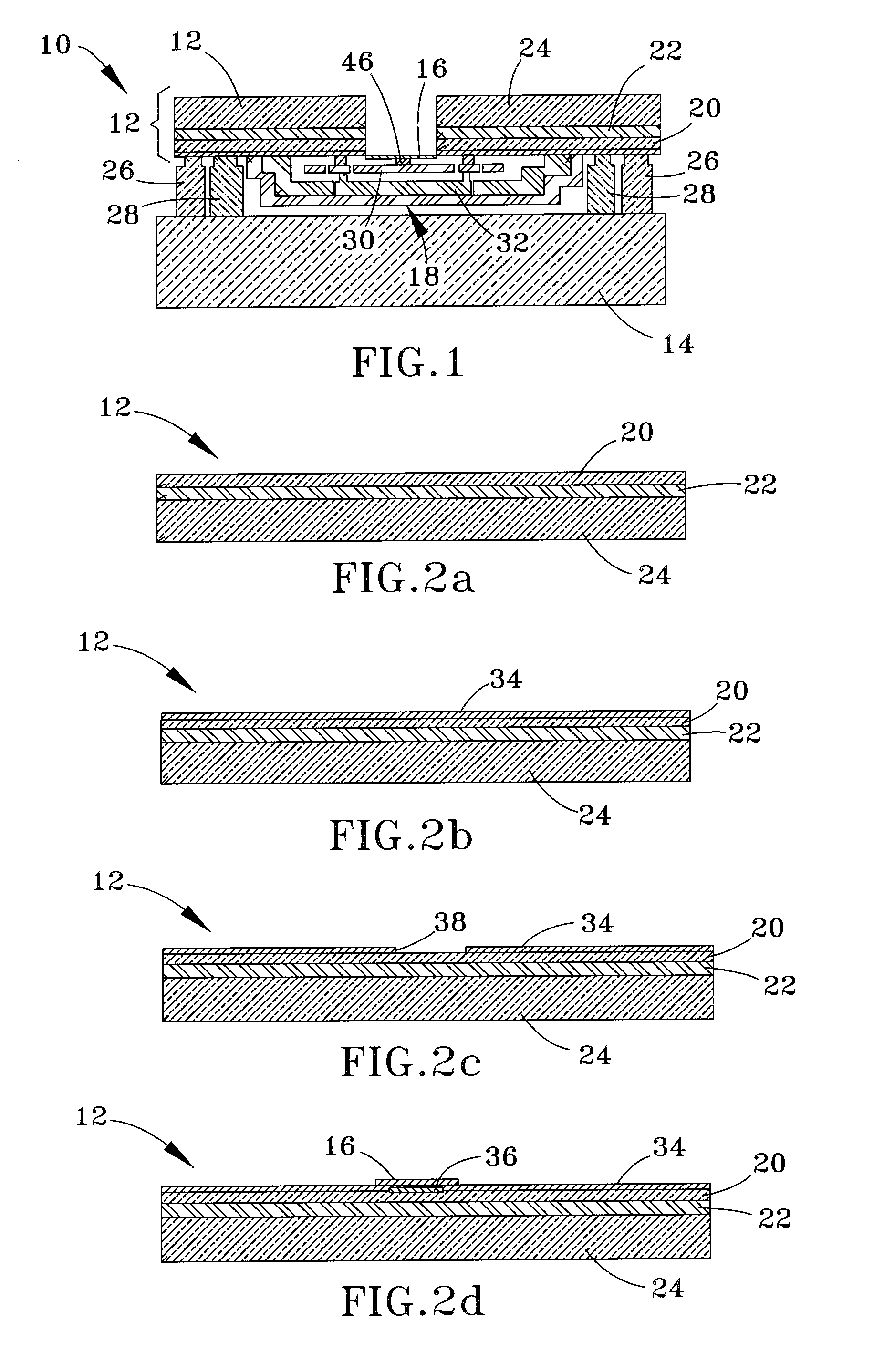

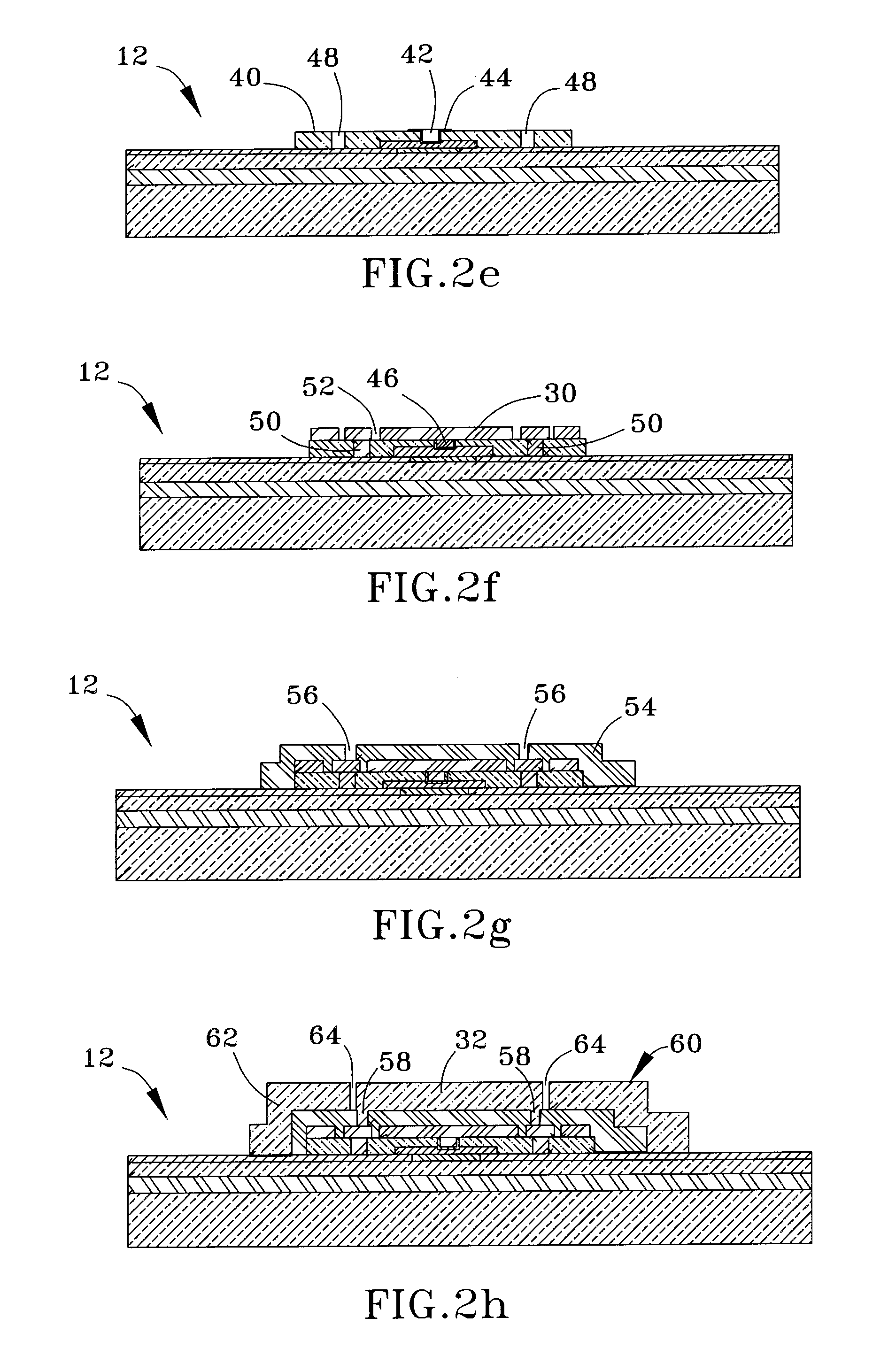

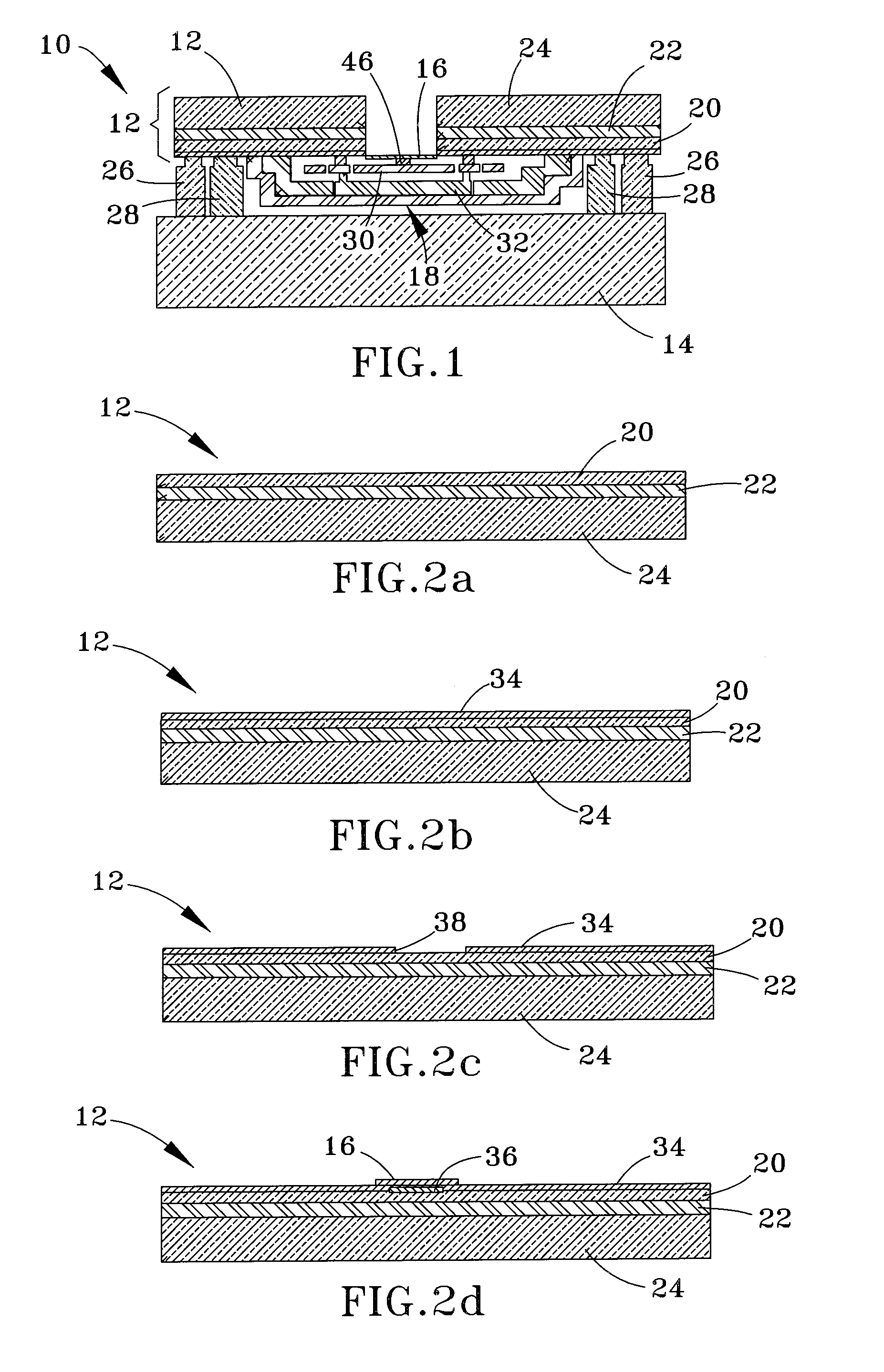

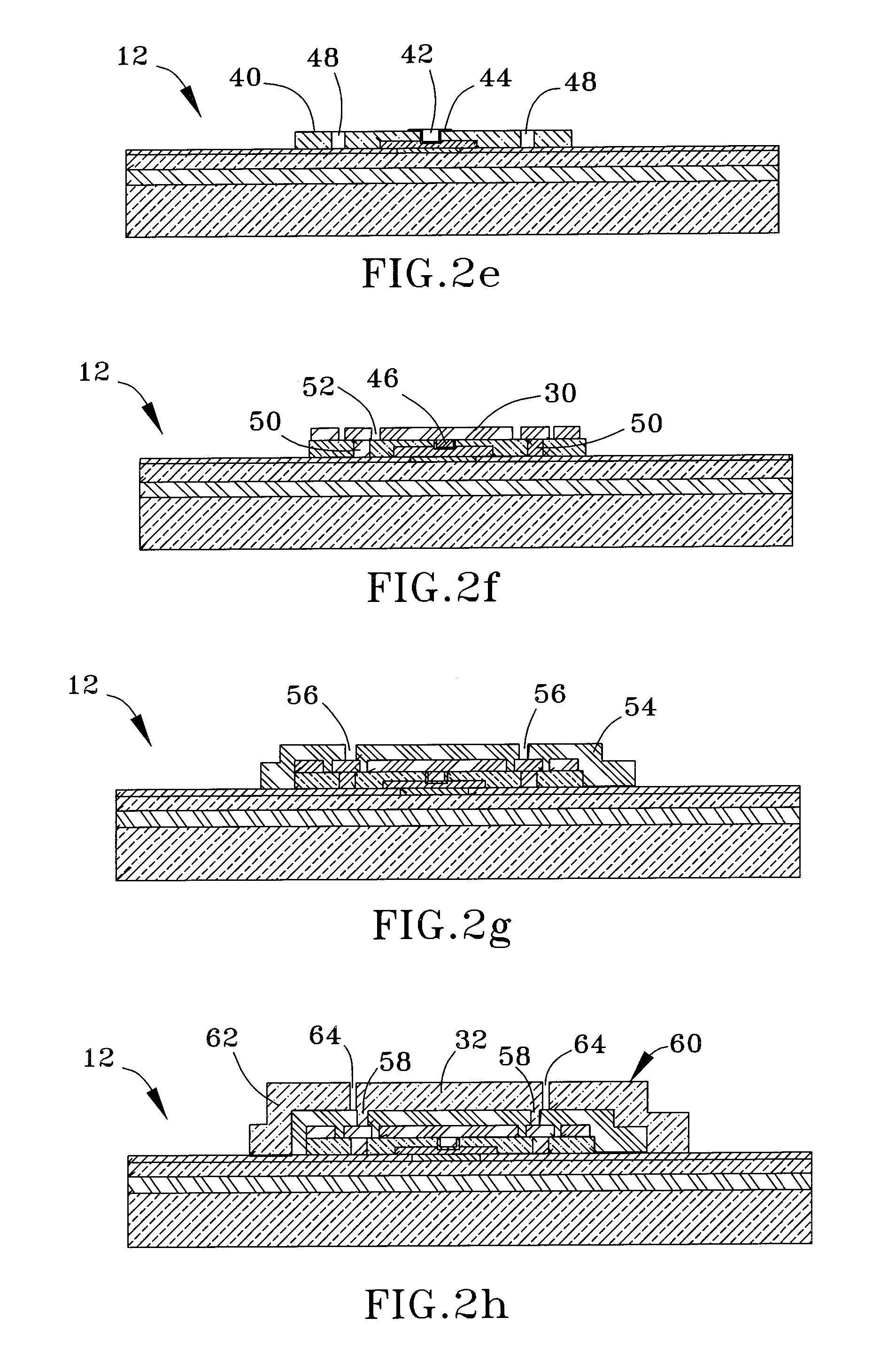

Capacitive pressure sensor and method therefor

ActiveUS20080053236A1Small die sizeIncreased pressure sensitivityElectrolytic capacitorsCapacitor with electrode distance variationCapacitive pressure sensorCapacitor

A capacitive pressure sensor and method for its fabrication. The sensor is fabricated from first and second wafers to have a mechanical capacitor comprising a fixed electrode and a moving electrode defined by a conductive plate. The sensor further has a diaphragm on a surface of the first wafer that is mechanically coupled but electrically insulated from the conductive plate. A conductive layer on the surface of the first wafer is spaced apart from the conductive plate to define the fixed electrode. The second wafer is bonded to the first wafer and carries interface circuitry for the sensor, including the conductive plate and the fixed electrode which are between the first and second wafers and electrically connected to the interface circuitry. At least an opening is present in the first wafer and its first conductive layer by which the diaphragm is released and exposed to an environment surrounding the sensor.

Owner:EVIGIA SYST

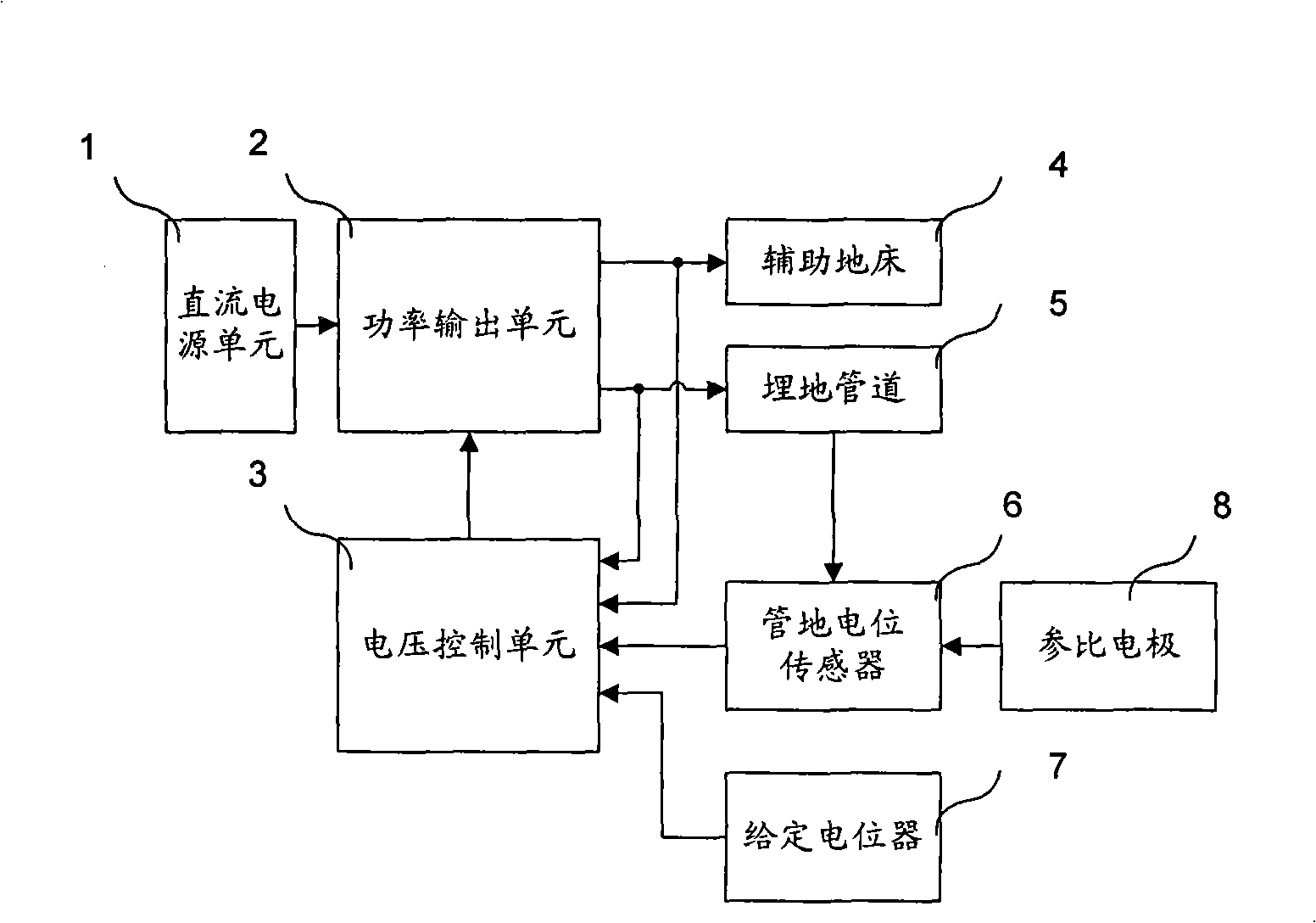

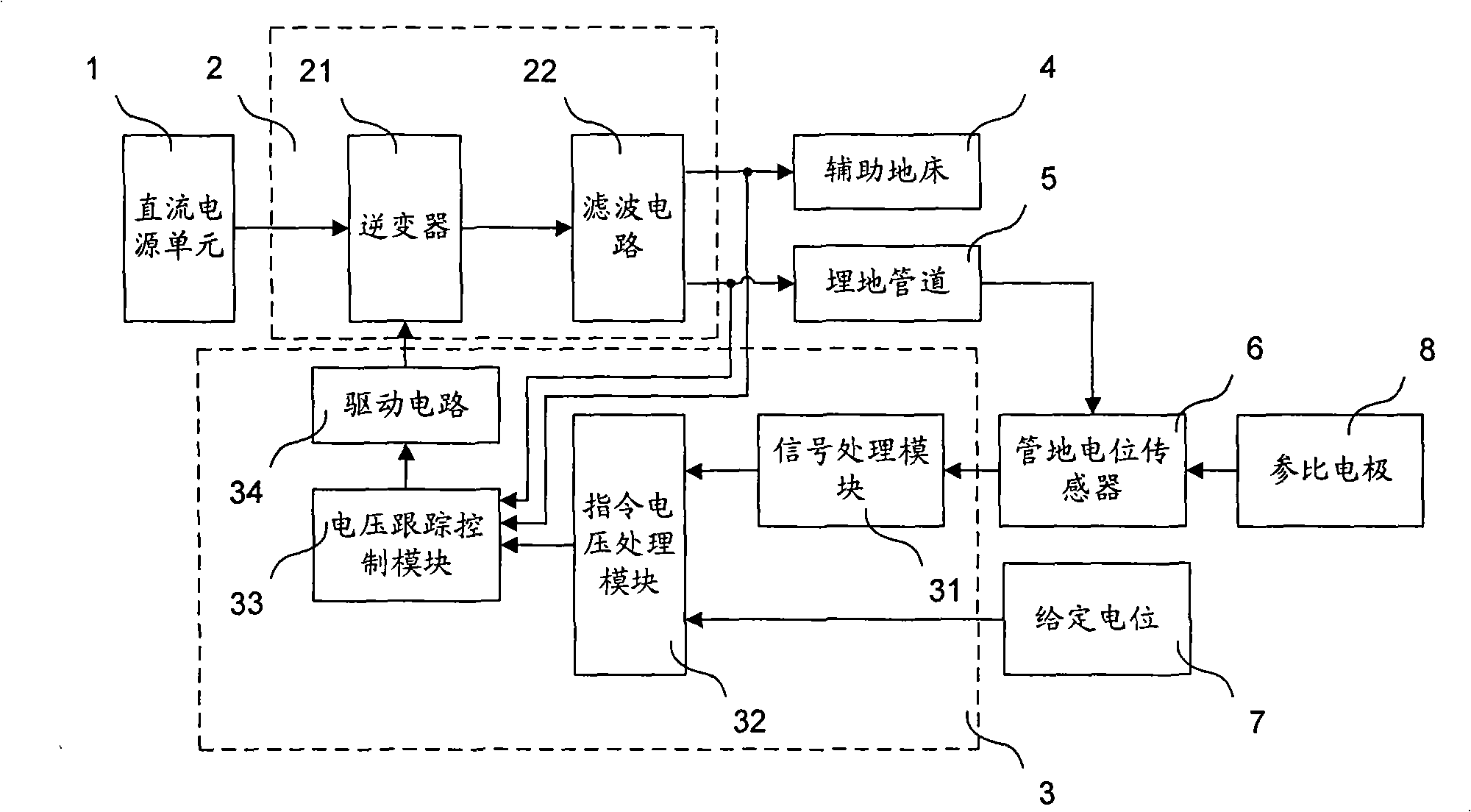

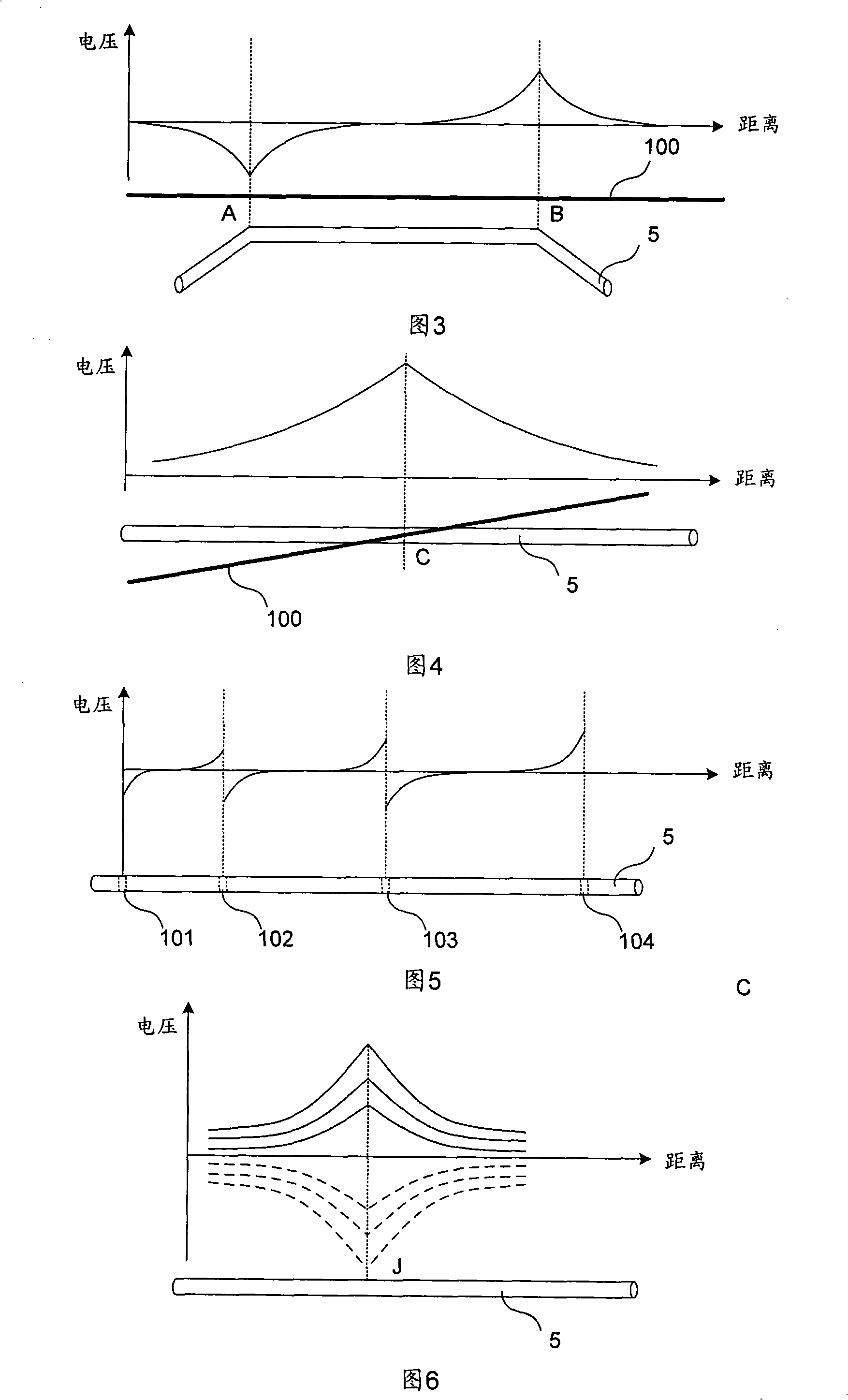

Active interference removing apparatus for buried pipeline

ActiveCN101343744AImprove output sensitivityEliminate distractionsCurrent/voltage measurementDisturbance voltageHigh pressure

The invention relates to a buried pipeline active disturbance removing device. The buried pipeline active disturbance removing device comprises a direct current power supply unit, a pipe-to-soil potential sensor, a given potentiometer, a voltage control unit and a power output unit, wherein the voltage control unit is used to generate the pulse width modulation (PWM) signal, and the power output unit is used to control the output of the internal invertor according to the pulse width modulation signal, and to output disturbance removing voltage which is performed with filtering treatment and which is equal to the pipe disturbance degree and is reverse to the direction to the auxiliary ground bed and the buried pipeline. Through adopting the tracking type PWM control method, the output of the buried pipeline active disturbance removing device of the invention can track the reference signal change of the directive voltage processing module in time, the buried pipeline active disturbance removing device has the advantages that the output sensitivity is high, the reaction speed is rapid, and the dynamic performance is good, and in particular the buried pipeline active disturbance removing device can be suitable for the eliminating of the disturbance caused by the high voltage transmission line and the space weather change.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

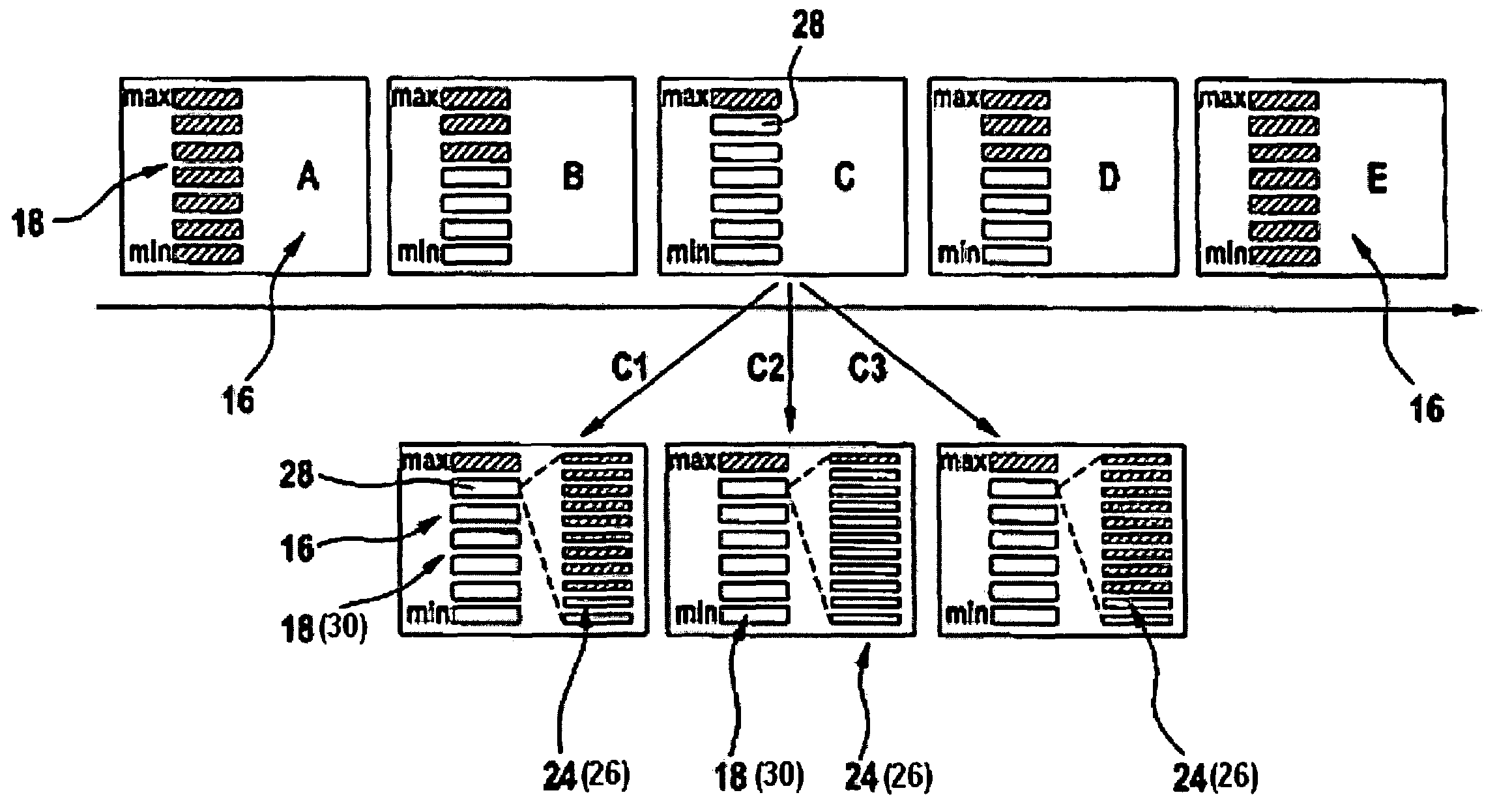

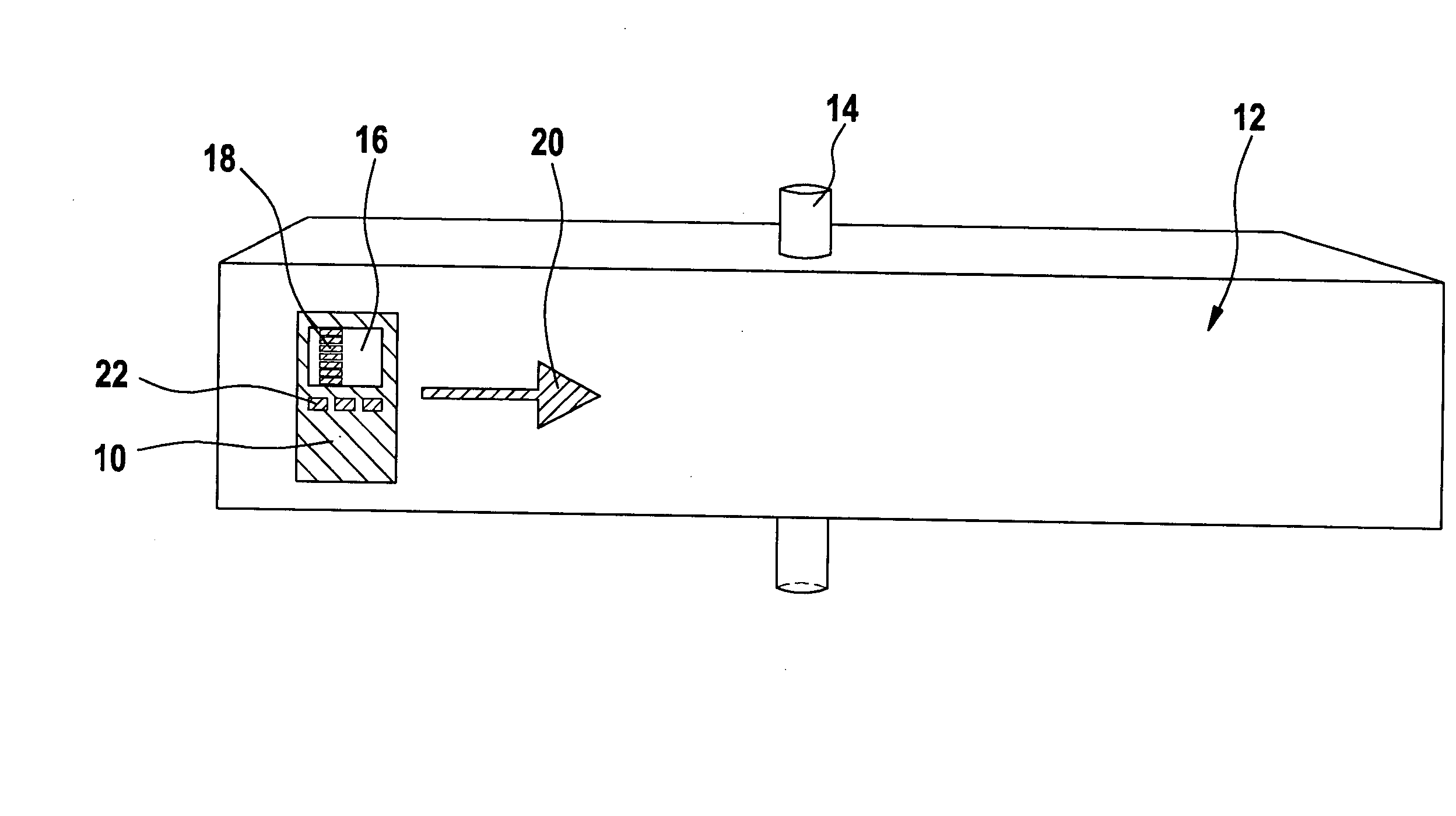

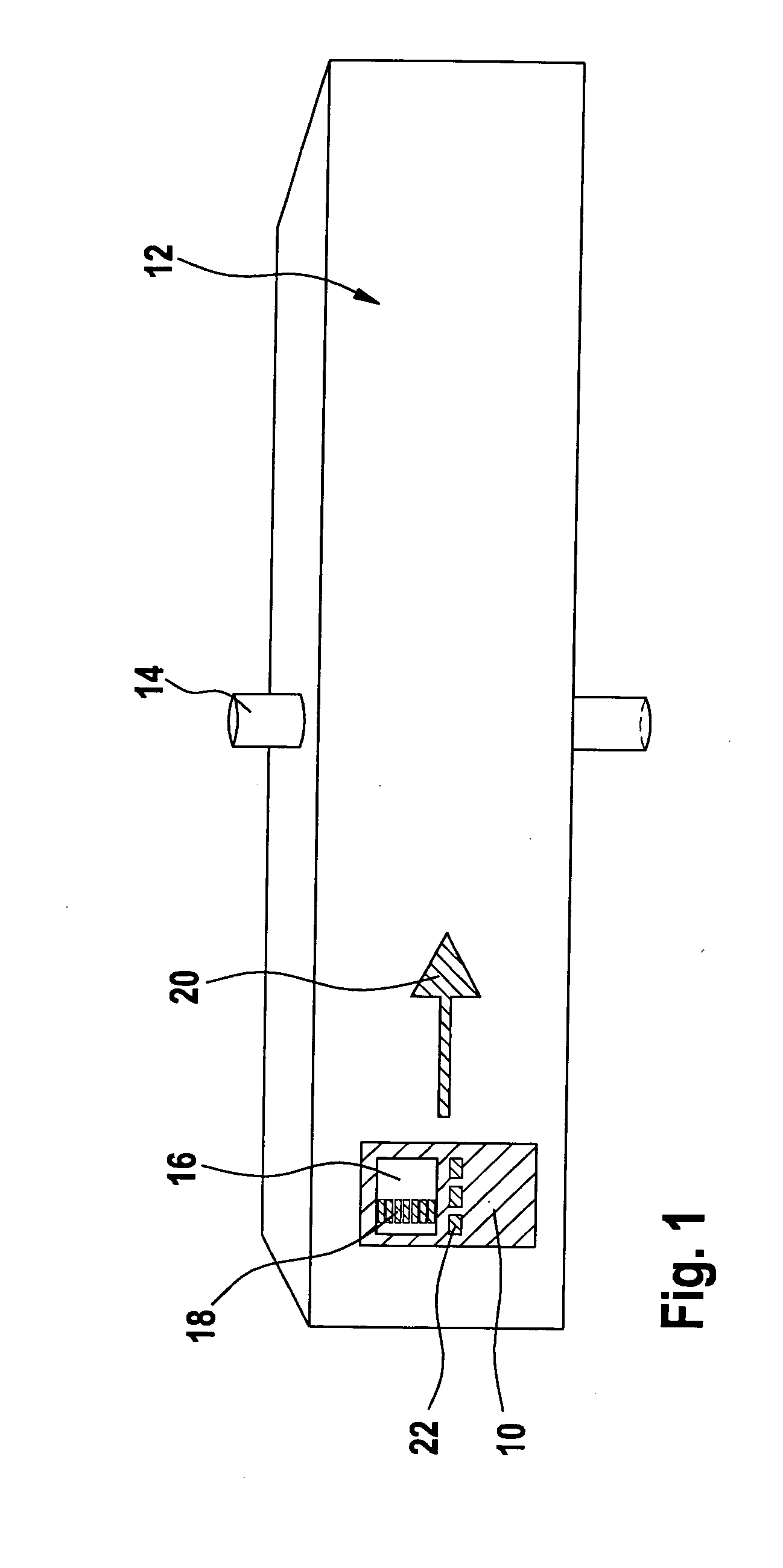

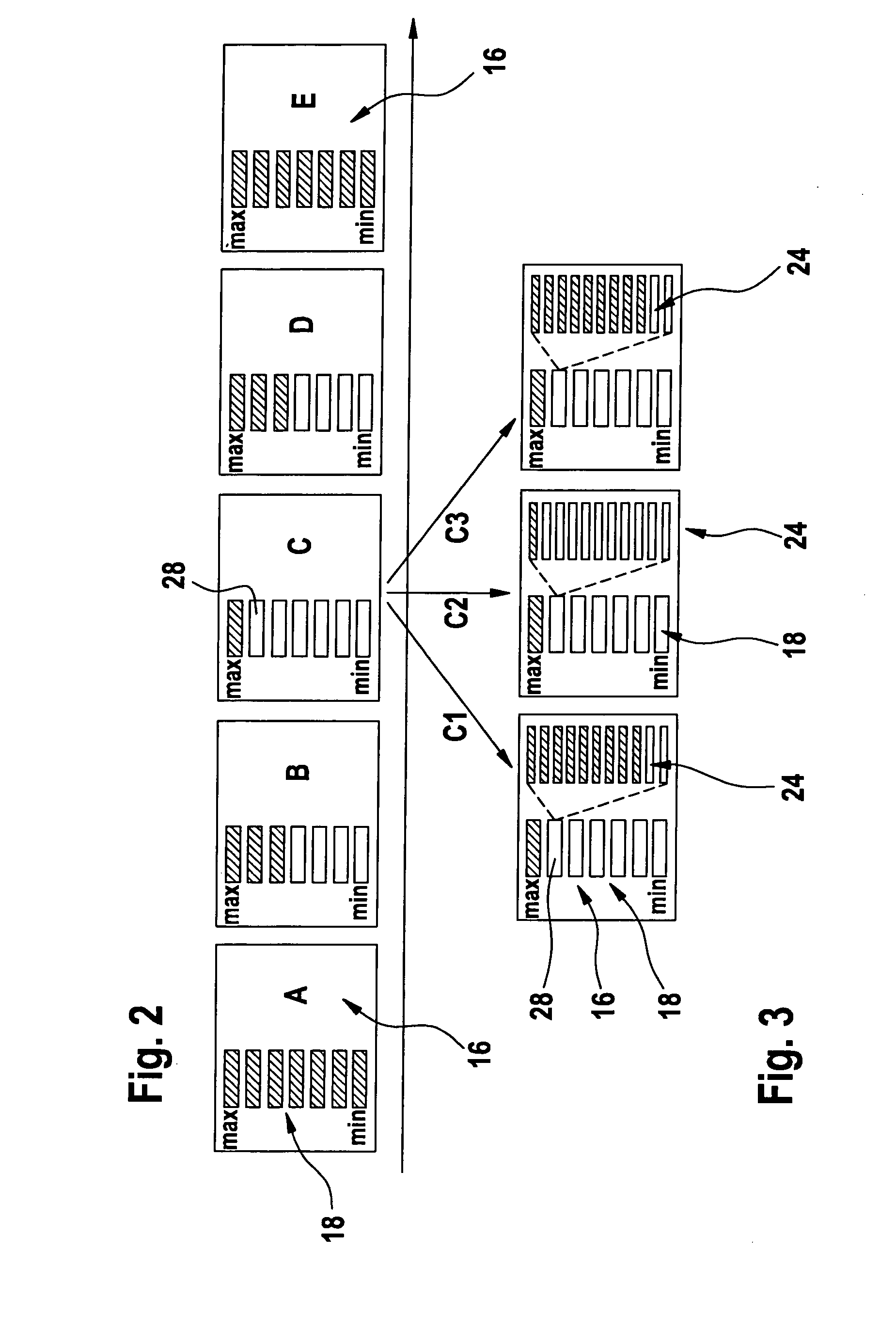

Locating device

ActiveUS7583071B2Easy to detectImprove displayabilityCurrent/voltage measurementMagnetic property measurementsHand heldEngineering

A locating device, in particular a hand-held locating device, for detecting objects enclosed in a medium, including an output unit for displaying at least one output variable correlated with a measuring signal of at least one sensor of the locating device, the output unit having a first dynamic range for displaying the output variable correlated with the measuring signal. At least one further dynamic range having a changed sensitivity compared to the first dynamic range is displayable via the display unit.

Owner:ROBERT BOSCH GMBH

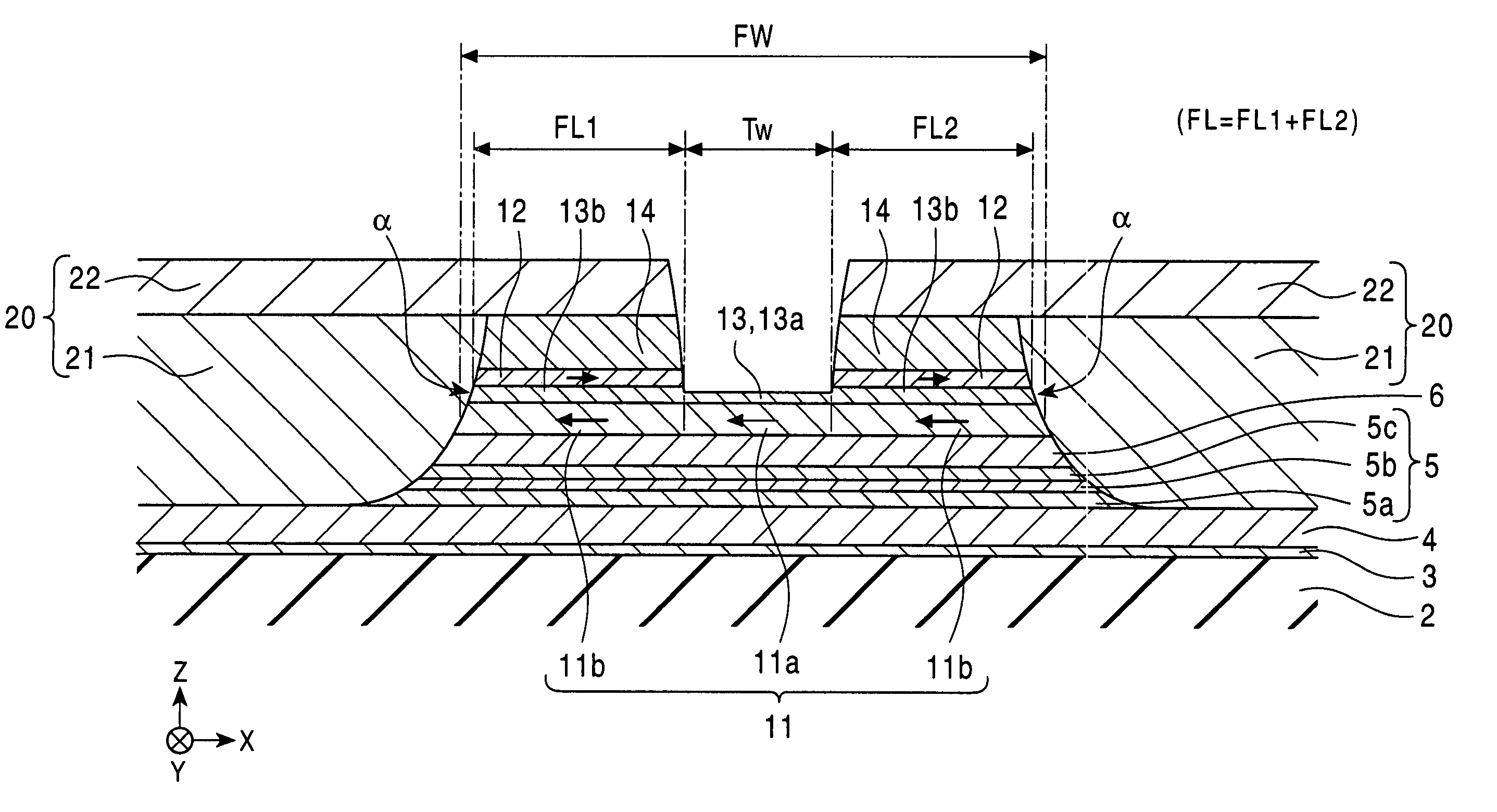

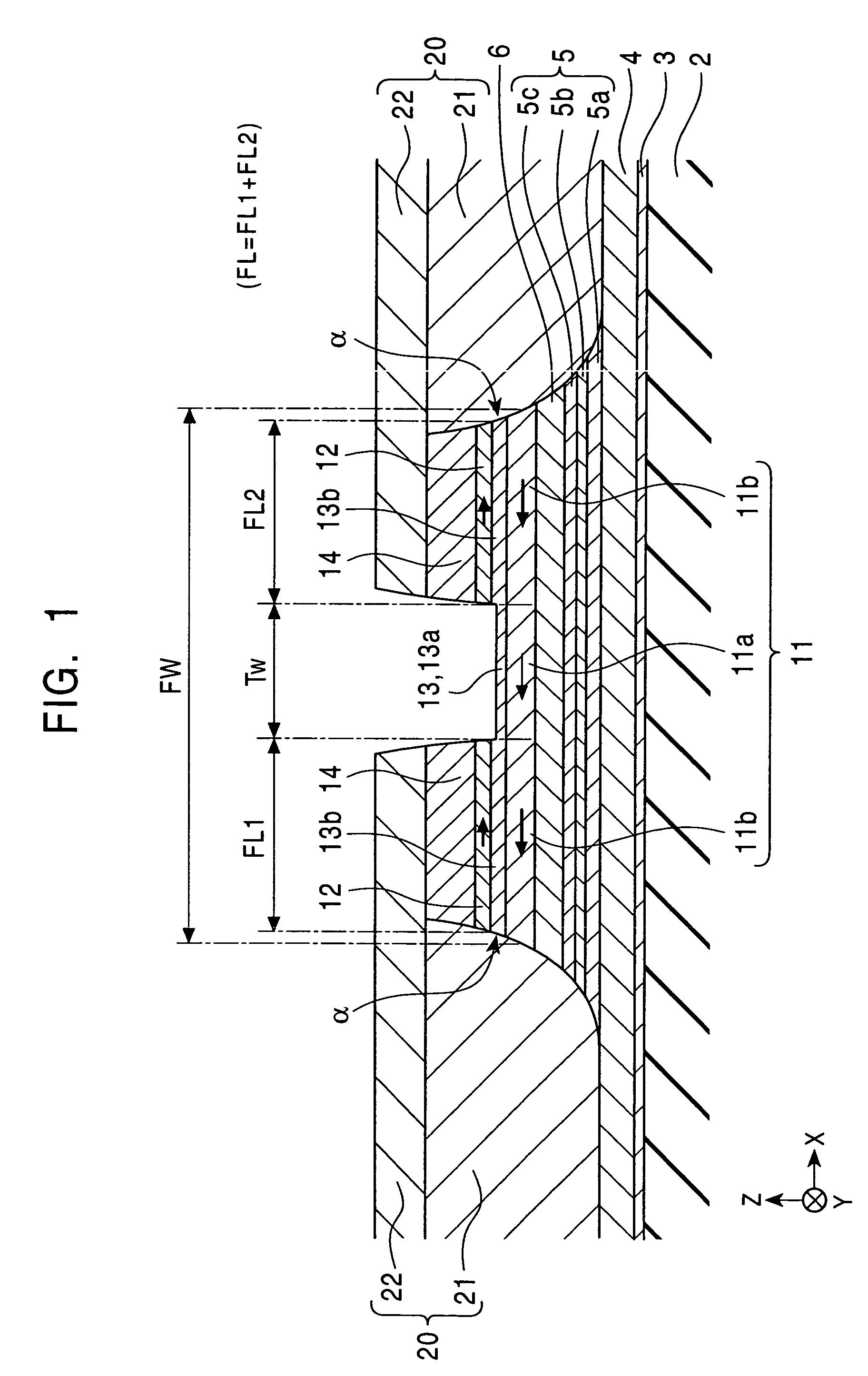

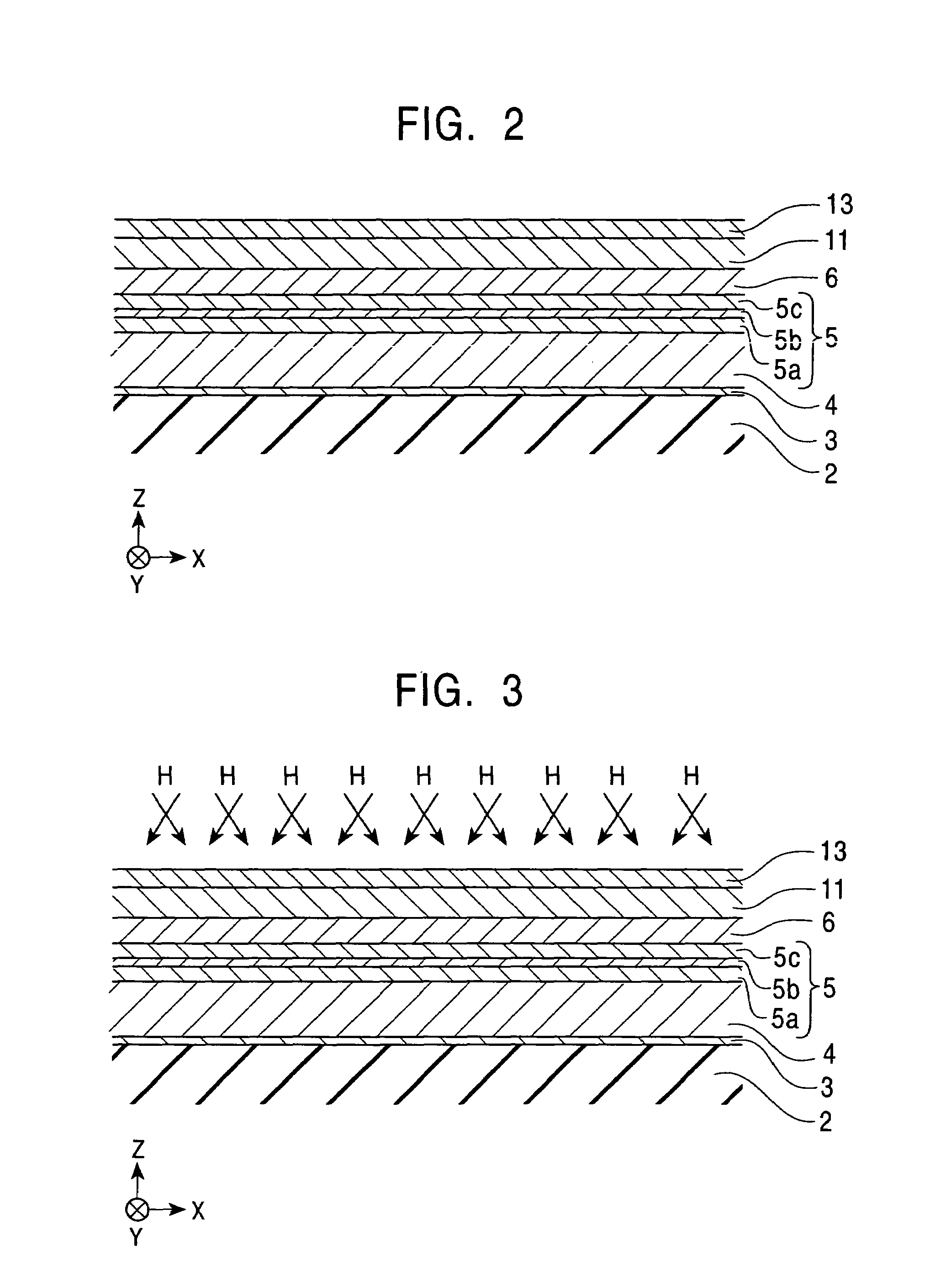

Giant magnetoresistive element

InactiveUS7079362B2Improve output sensitivityElement resistance is decreasedNanomagnetismMagnetic measurementsMagnetizationNon magnetic

A giant magnetoresistive (GMR) element includes a first antiferromagnetic layer, a pinned magnetic layer having a magnetization direction pinned by the first antiferromagnetic layer, a nonmagnetic material layer, a free magnetic layer having a magnetization direction with a central portion changing with an external magnetic field, a nonmagnetic layer, ferromagnetic layers formed on both sides of the nonmagnetic layer, and second antiferromagnetic layers for aligning the magnetization direction of the ferromagnetic layers perpendicular to that of the pinned magnetic layer. The magnetization directions of the free magnetic and ferromagnetic layers are antiparallel to each other. At least the free magnetic layer, the nonmagnetic layers and the ferromagnetic layers have continuous surfaces α at both end surfaces in the track width direction. First electrode layers are provided in contact with the continuous surfaces α, and second electrode layers are provided on the first electrode layers and the second antiferromagnetic layers.

Owner:TDK CORPARATION

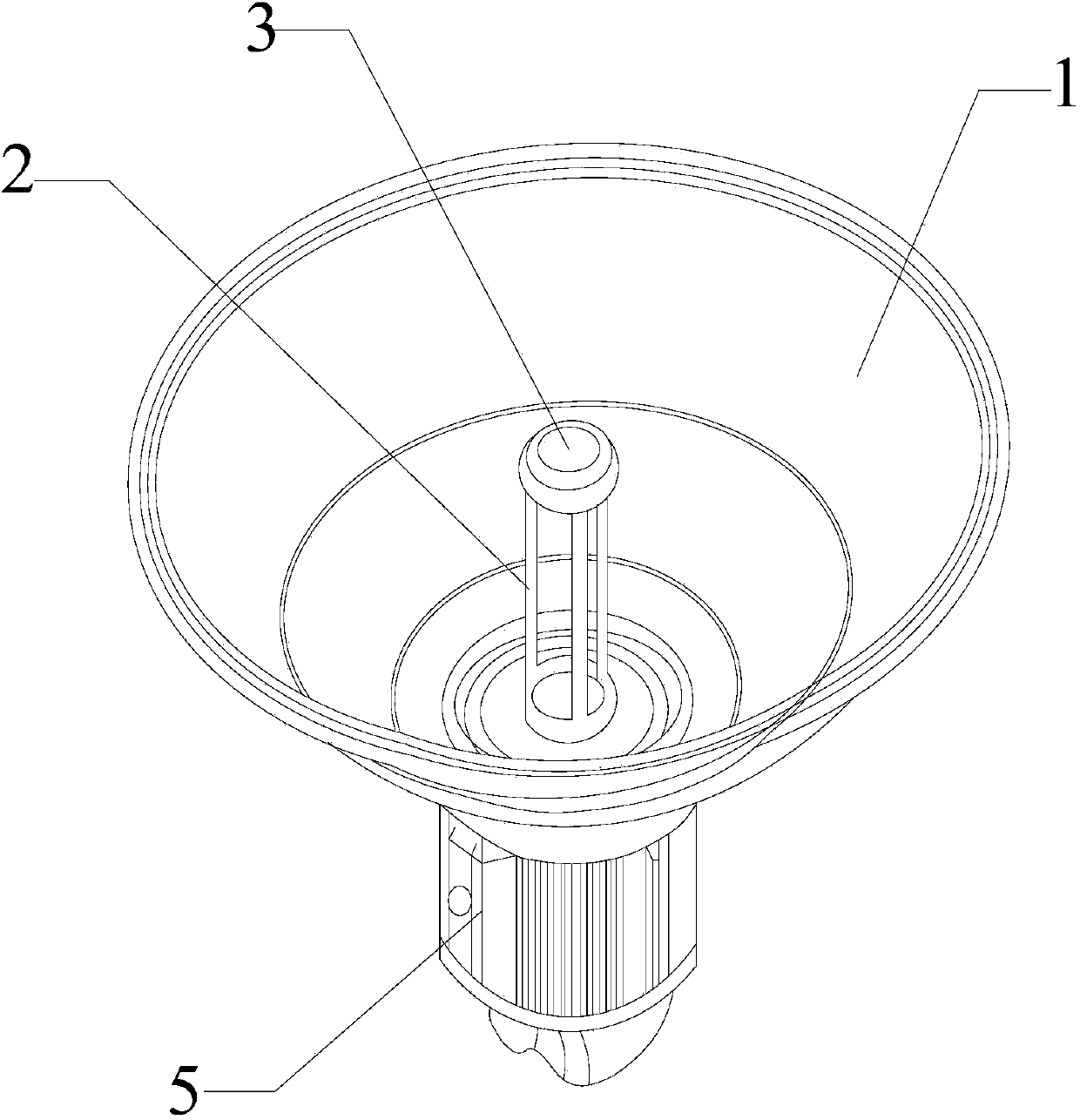

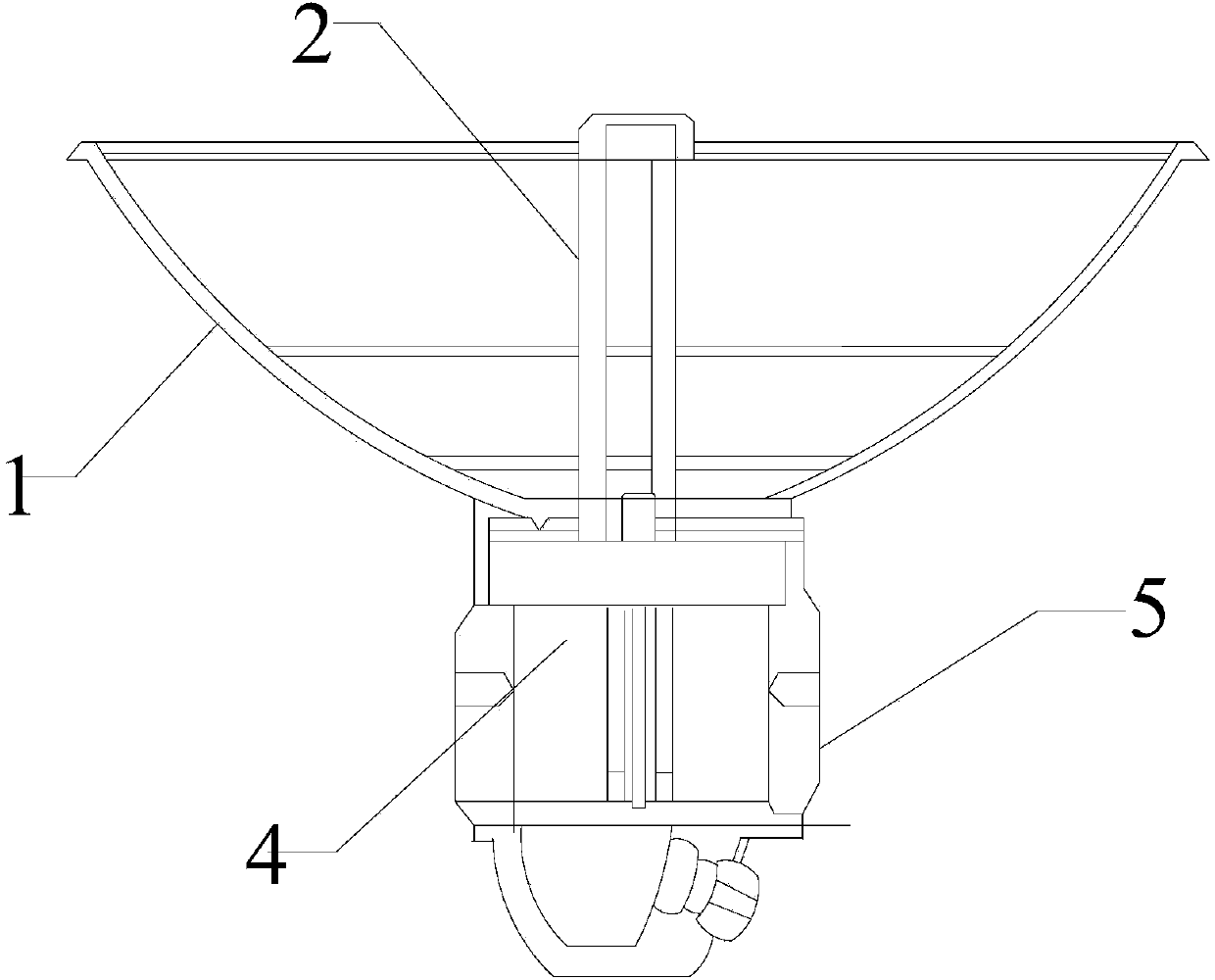

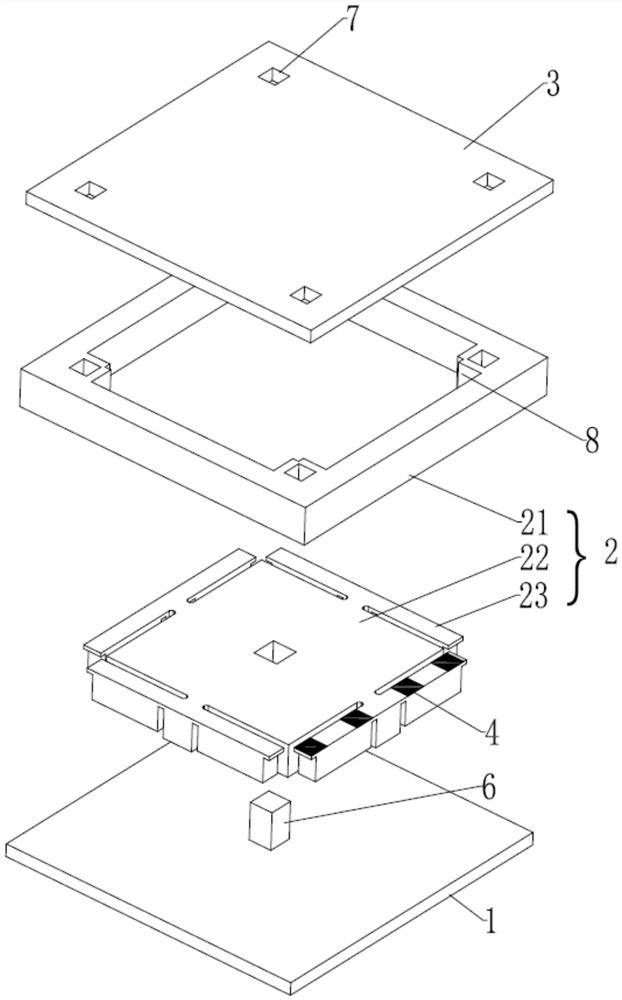

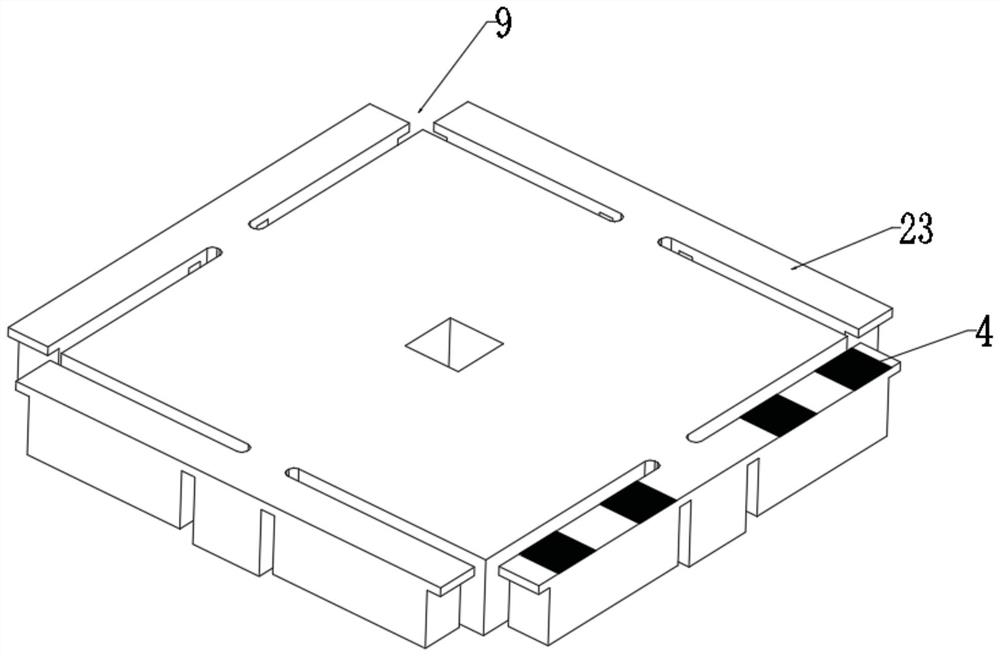

Sound focusing voice pickup device

ActiveCN103813248AIncreased sonic energyImprove output sensitivityElectrostatic transducer microphonesEngineeringSound wave

The invention discloses a sound focusing voice pickup device, comprising a concave surface reflector with increased radian from the bottom to the top and increased vertical distance between the cambered surface and the center line, a fixing shelf is arranged at the centre of the bottom of the concave surface reflector; the fixing shelf comprises a support rod connected to the concave surface reflector at one end and connected with an array microphone at the other end; the array microphone comprises a PCB board, which sleeves a guard circle, and the guard circle is connected to the fixing shelf, the PCB board is welded with a plurality of MEMS microphones at the side facing the bottom of the concave surface reflector, the PCB board connects a wire, which is connected with DSP signal processing module while penetrating the bottom of the concave surface reflector. The reflective sound wave is enhanced at one focal point and the output sensitivity is raised; the MEMS microphones have good repeatability and consistency and resist humid environment and temperature shock; the microphone array signal can support the work for the speech recognition, speech enhancement and speech separation modules.

Owner:金如利

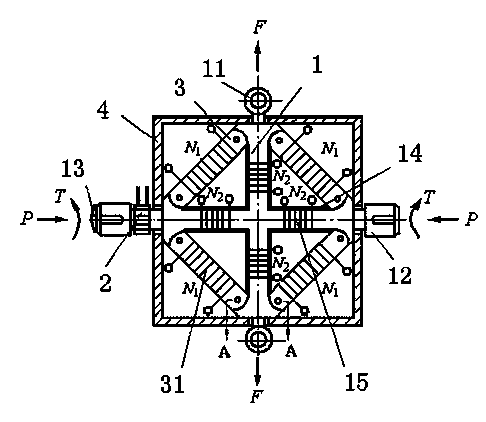

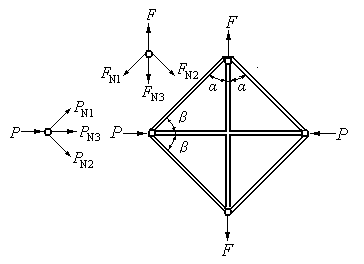

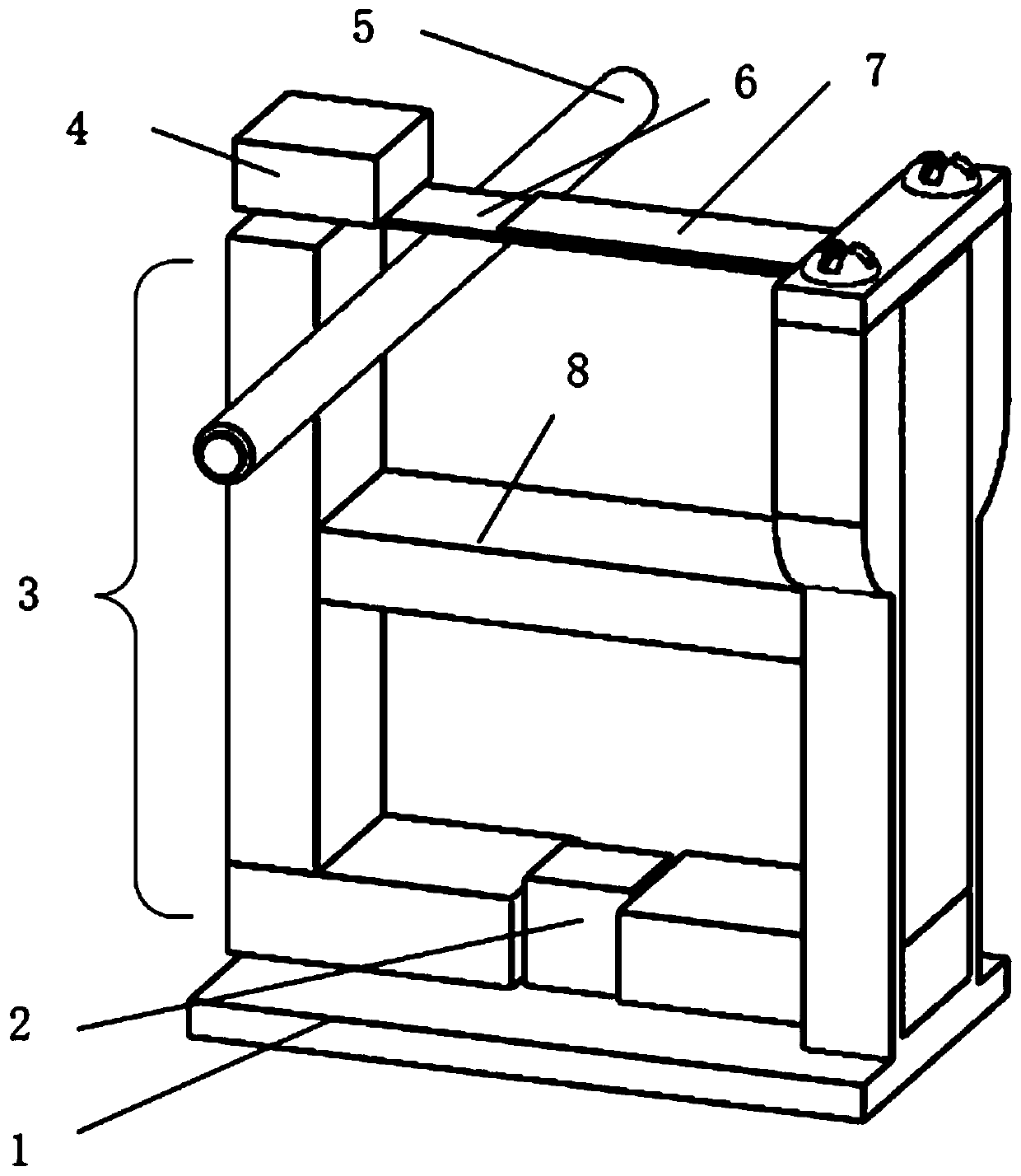

Multifunctional force cell sensor

InactiveCN103439034AHigh outputImprove output sensitivityForce measurement by measuring magnetic property varationWork measurementPull forceCoupling

The invention discloses a multifunctional force cell sensor. The multifunctional force cell sensor comprises a cross elastic shaft, an output and input collecting ring, magnetic conductive connecting rods, a Fe-based nanometer microcrystalline alloy adhesion layer, excitation coils, measuring coils and an anti-magnetic interference shielding cover, wherein the four arms of the cross elastic shaft have the same length, the two ends in the vertical direction of the cross elastic shaft are provided with pulling force rings for pulling force measuring; the two ends in the horizontal direction of the cross elastic shaft are respectively provided with a shaft coupling for torque measuring and a pressure head for pressure measuring; the Fe-based nanometer microcrystalline alloy adhesion layer is attached to the bearing surface of the cross elastic shaft; the surface of the Fe-based nanometer microcrystalline alloy adhesion layer is wound by the measuring coils; the magnetic conductive connecting rods are connected with the end portions of the cross elastic shaft and thus a rhombus magnetic conductive steel frame is formed; the magnetic conductive connecting rods are wound by the excitation coils; and the whole sensor is arranged inside the anti-magnetic interference shielding cover. The multifunctional force cell sensor can measure not only pulling force and but also pressure and torque, and also has higher precision and sensitivity.

Owner:HUAIHAI INST OF TECH

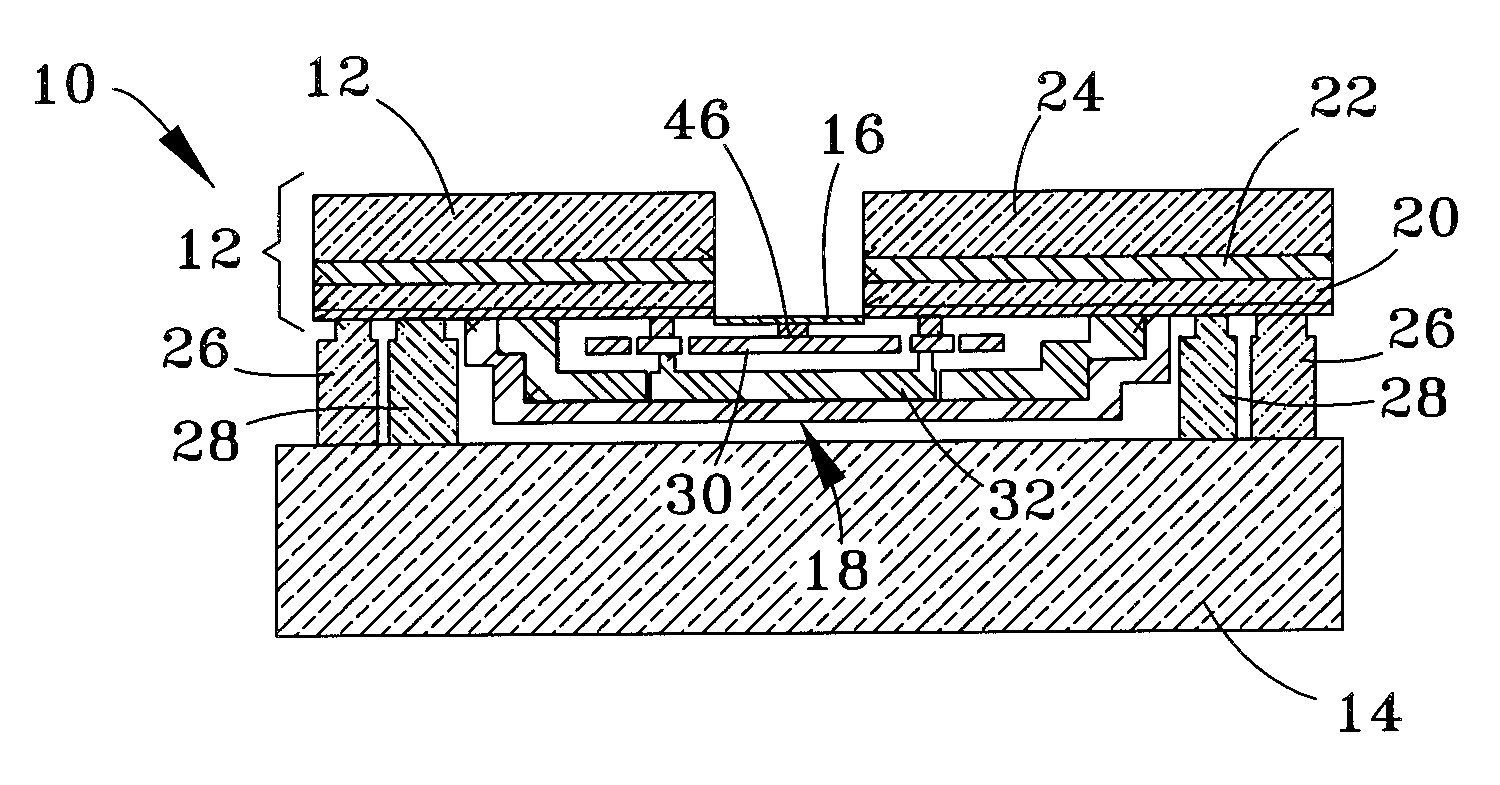

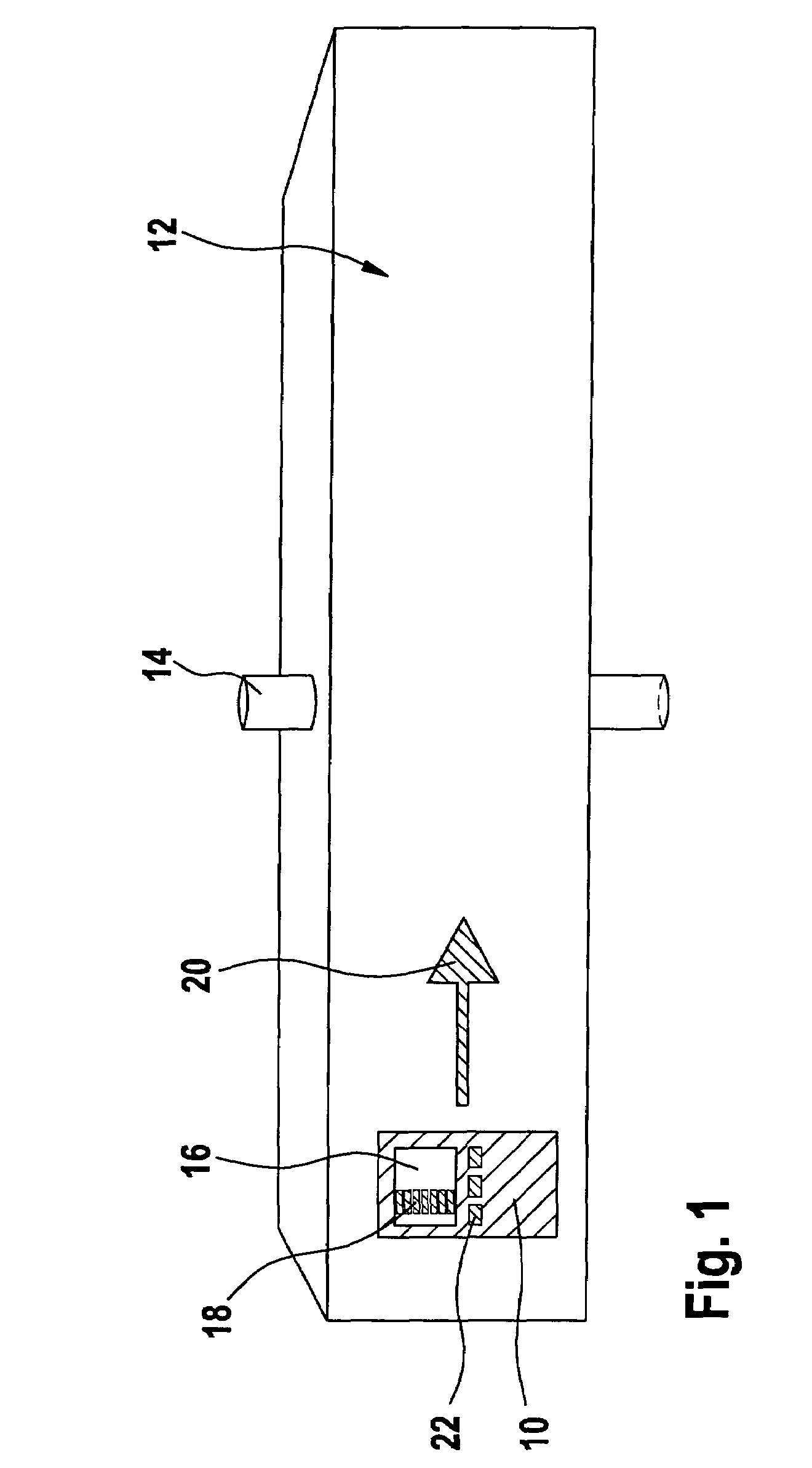

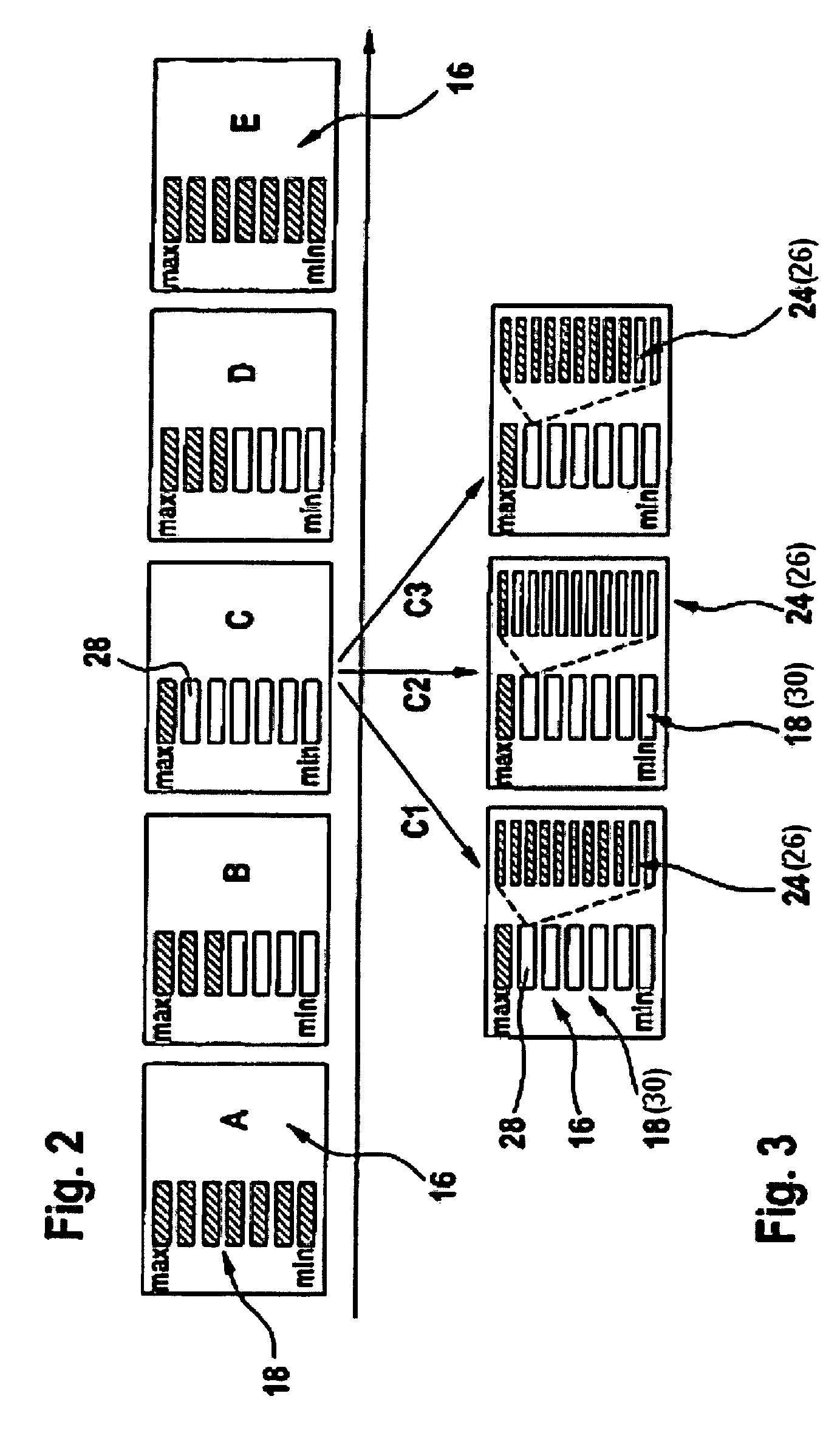

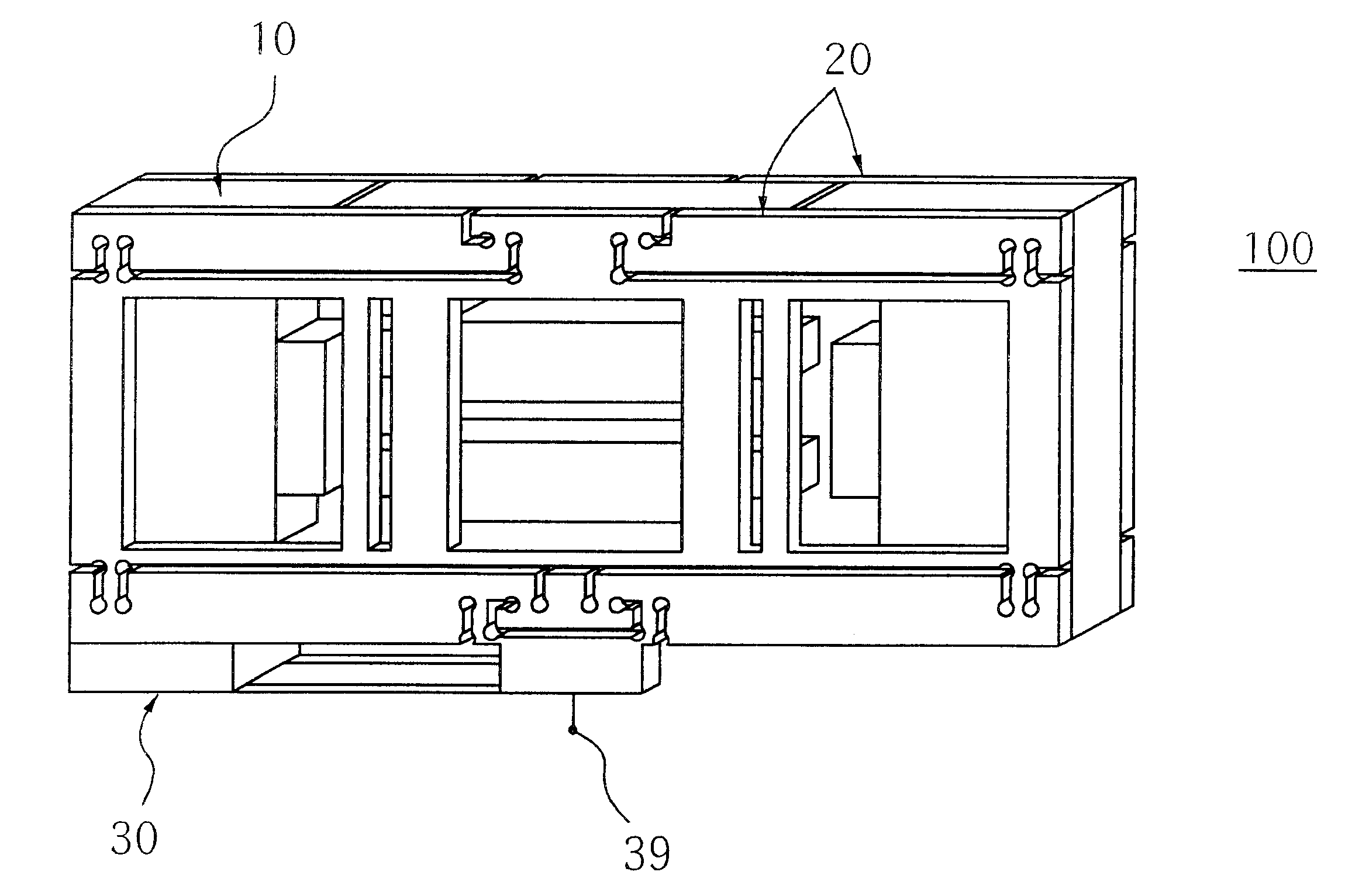

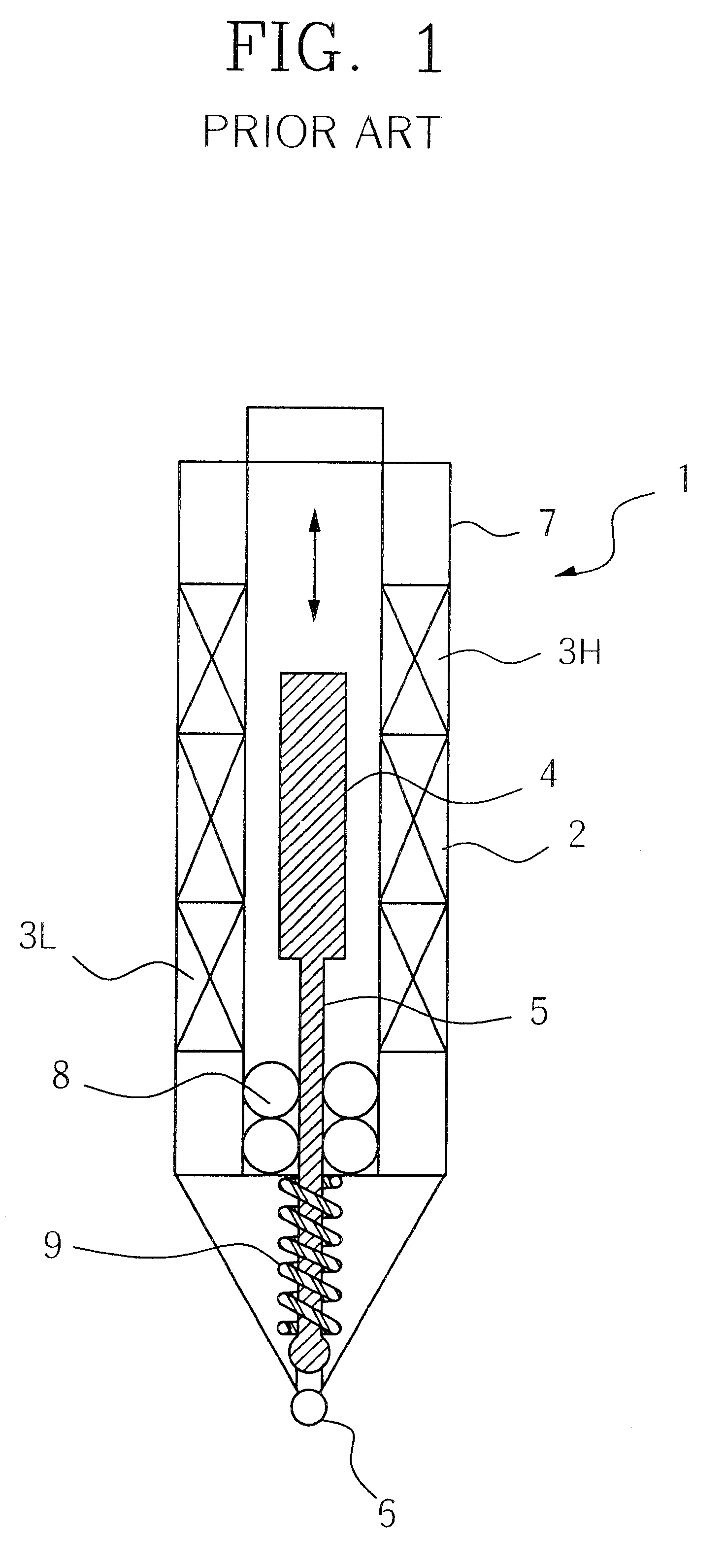

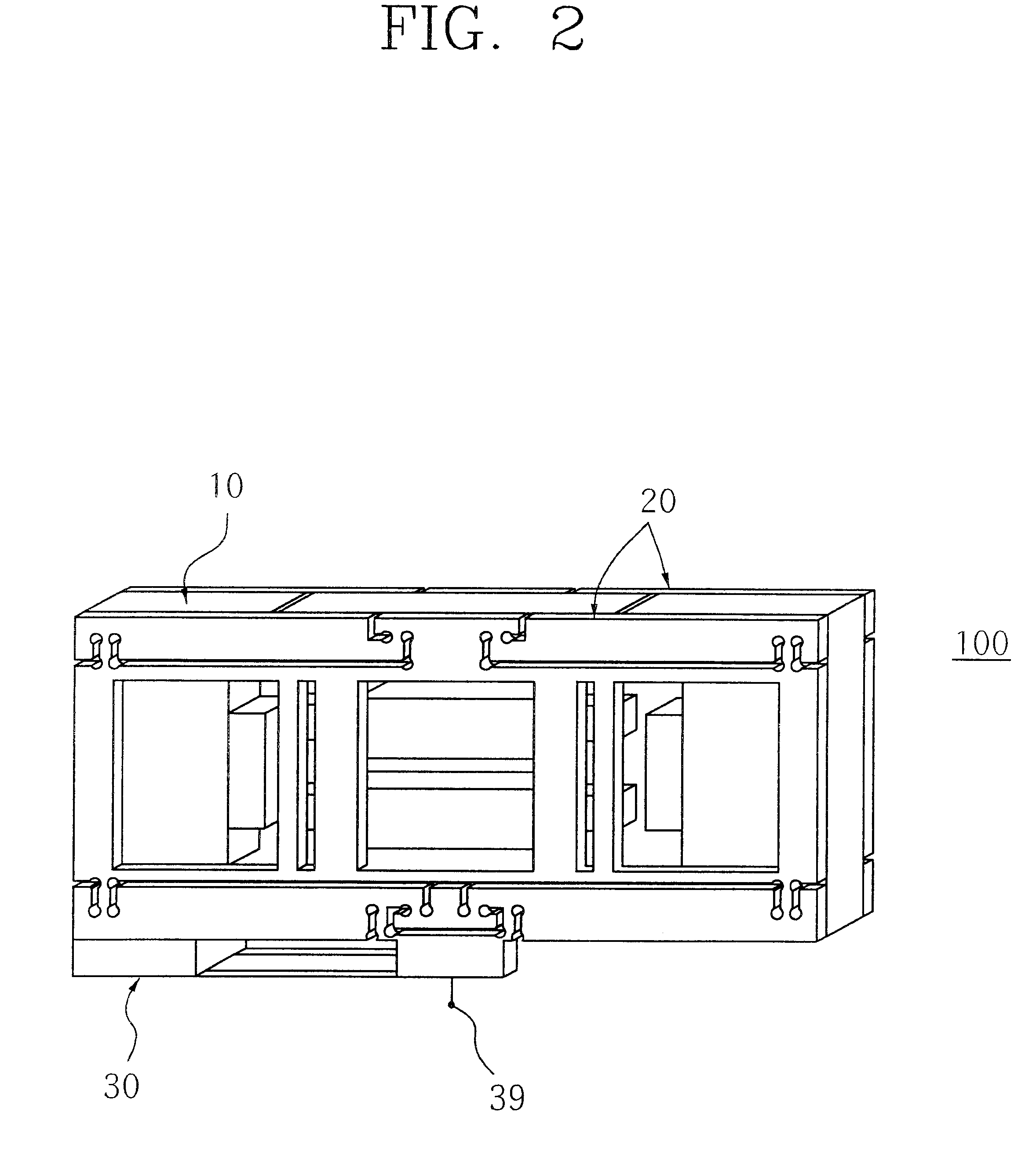

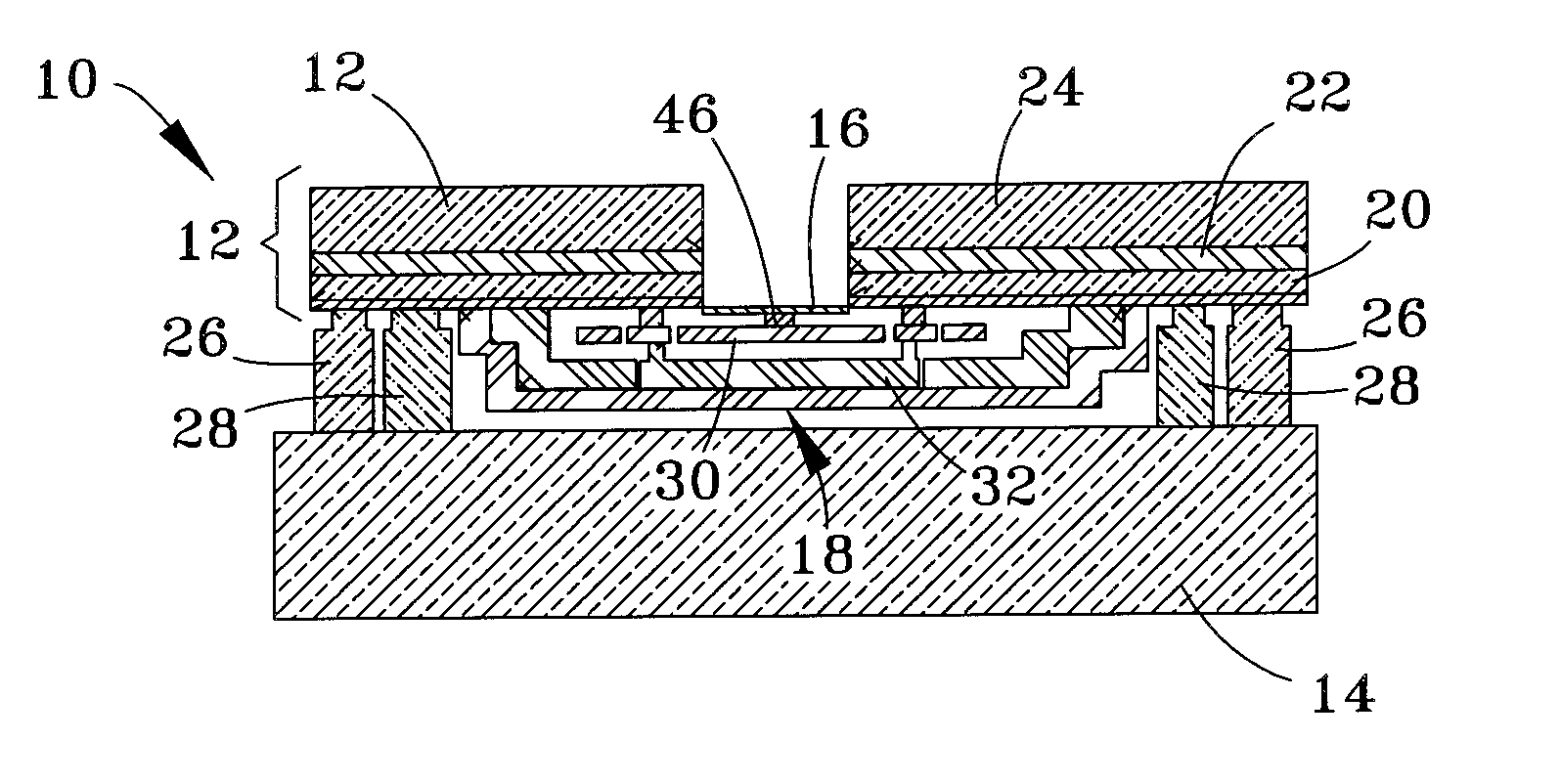

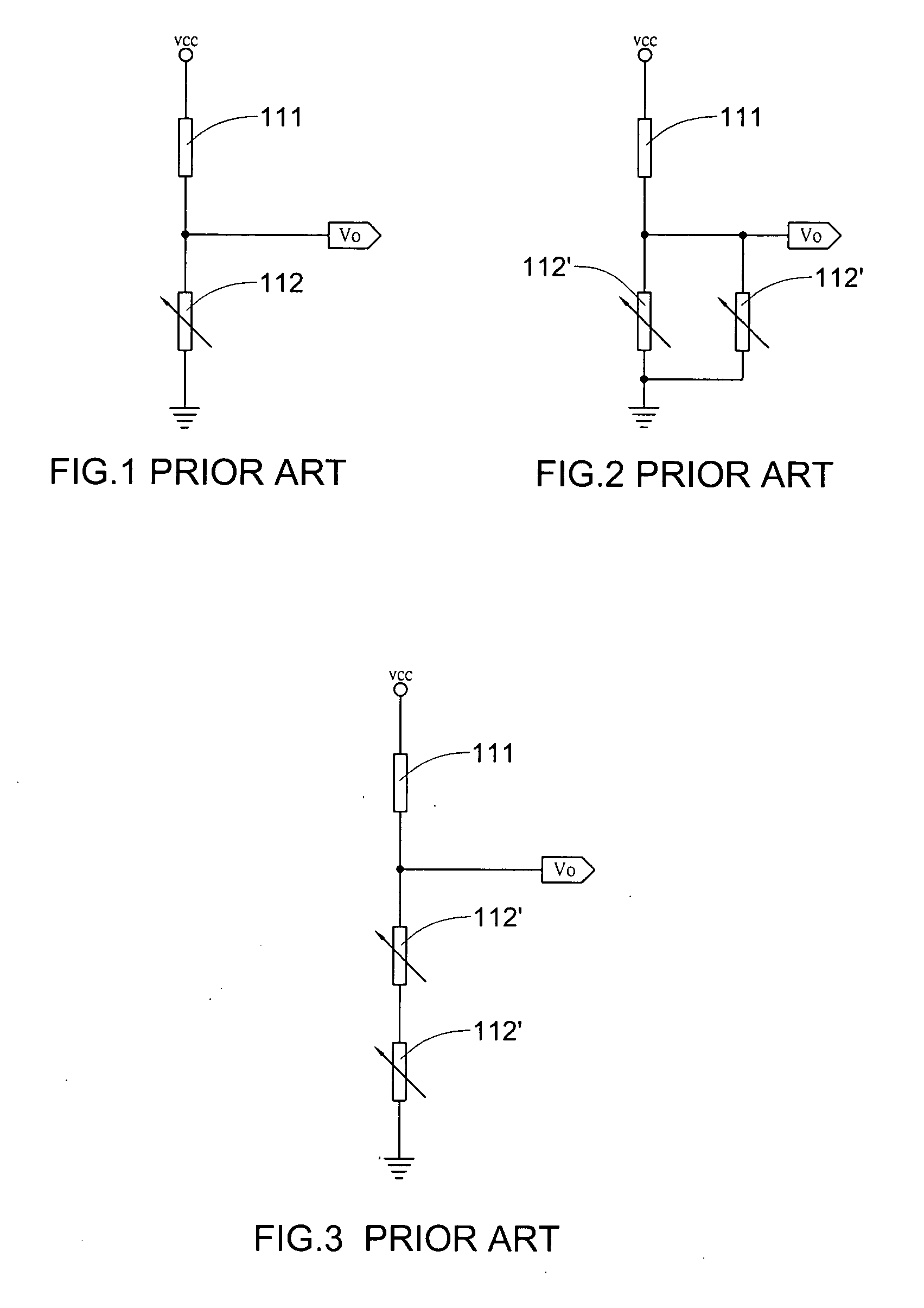

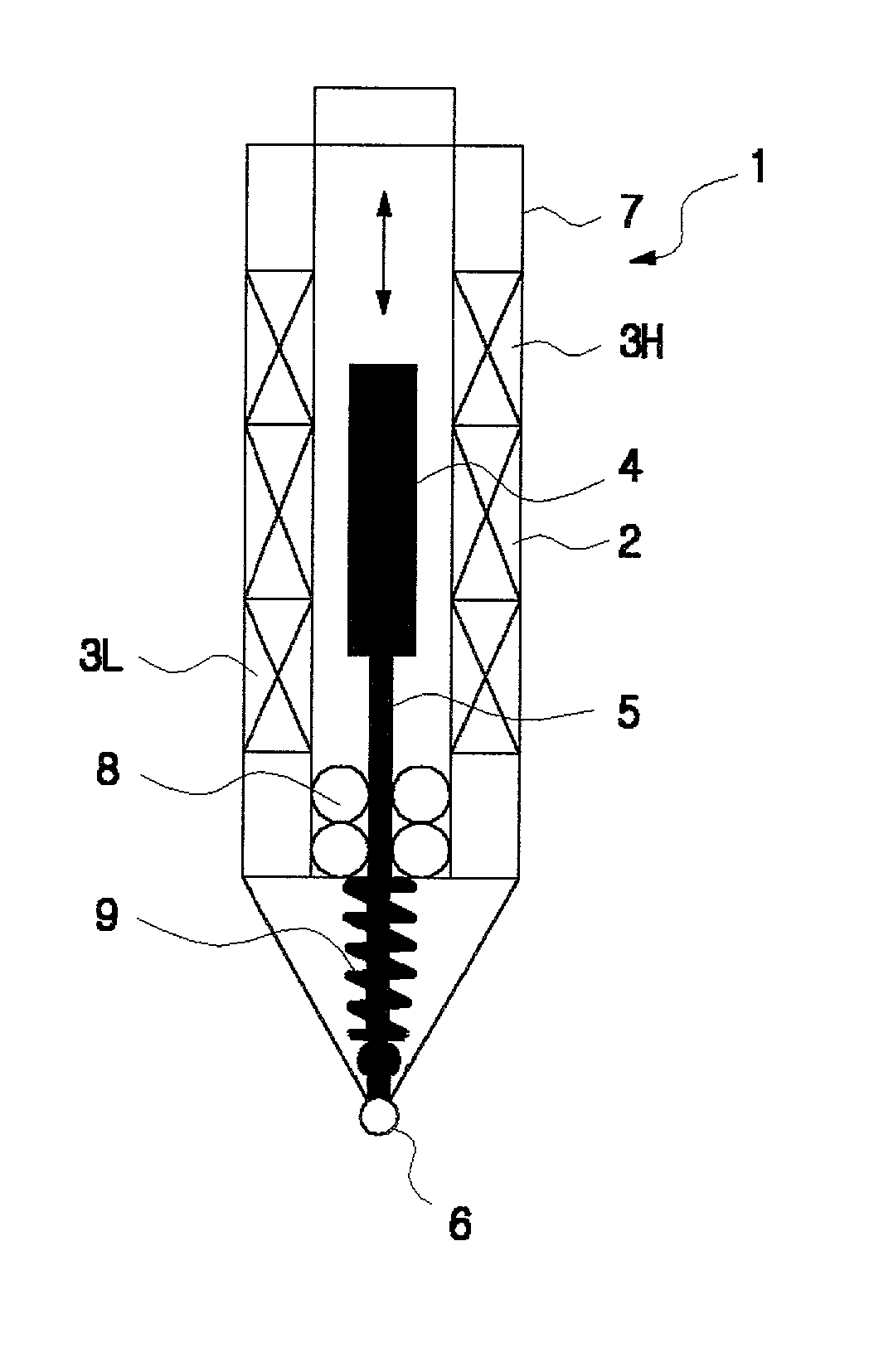

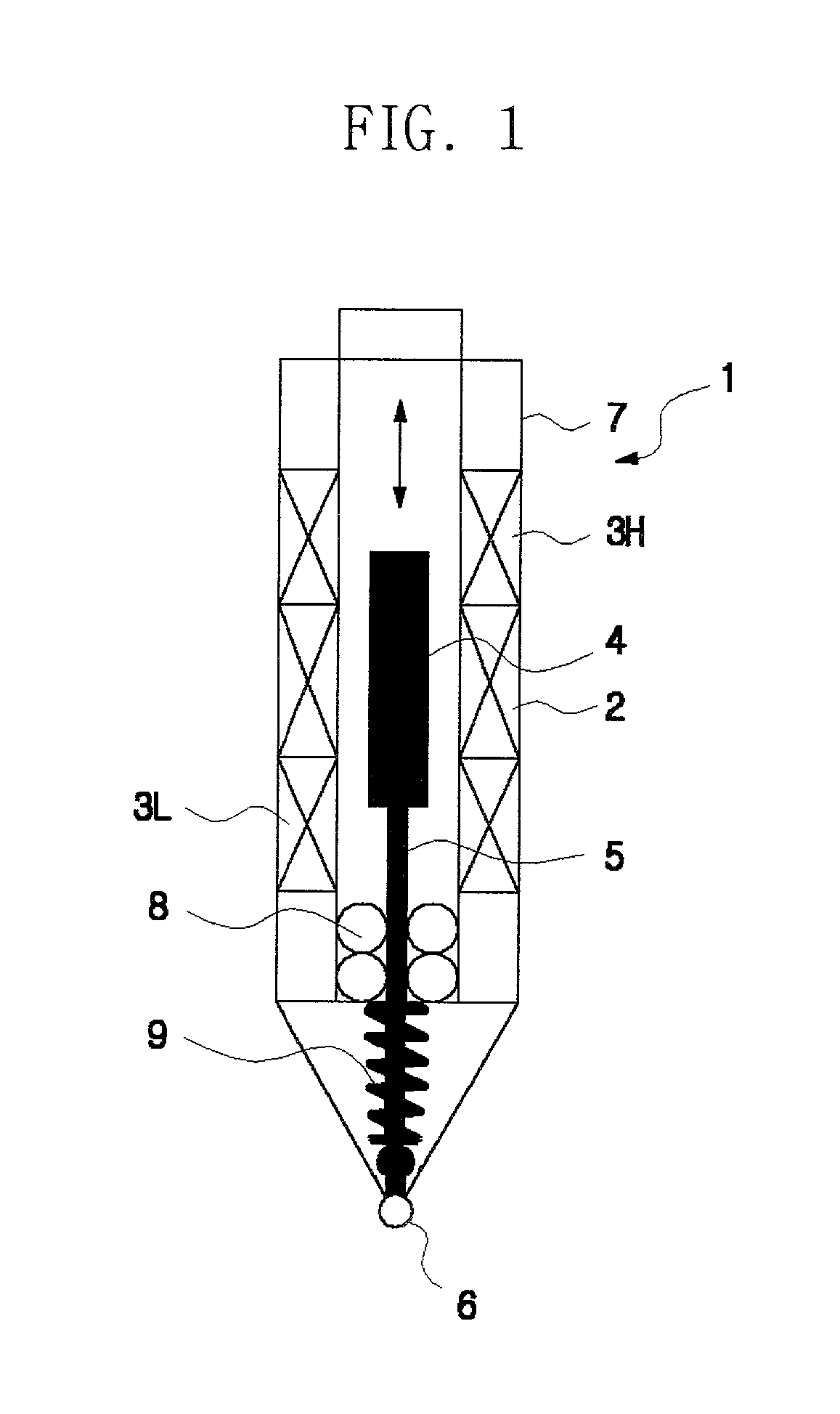

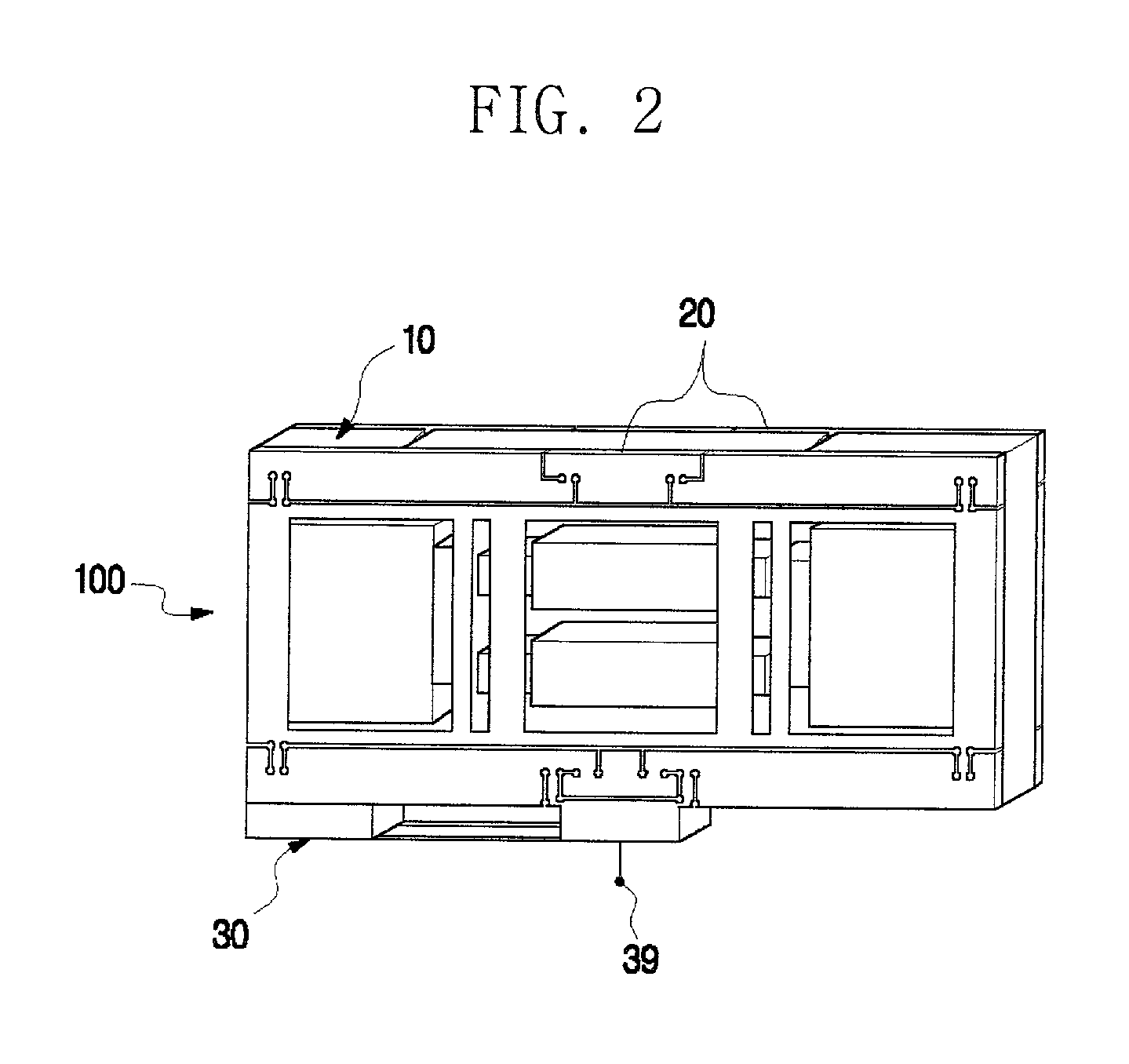

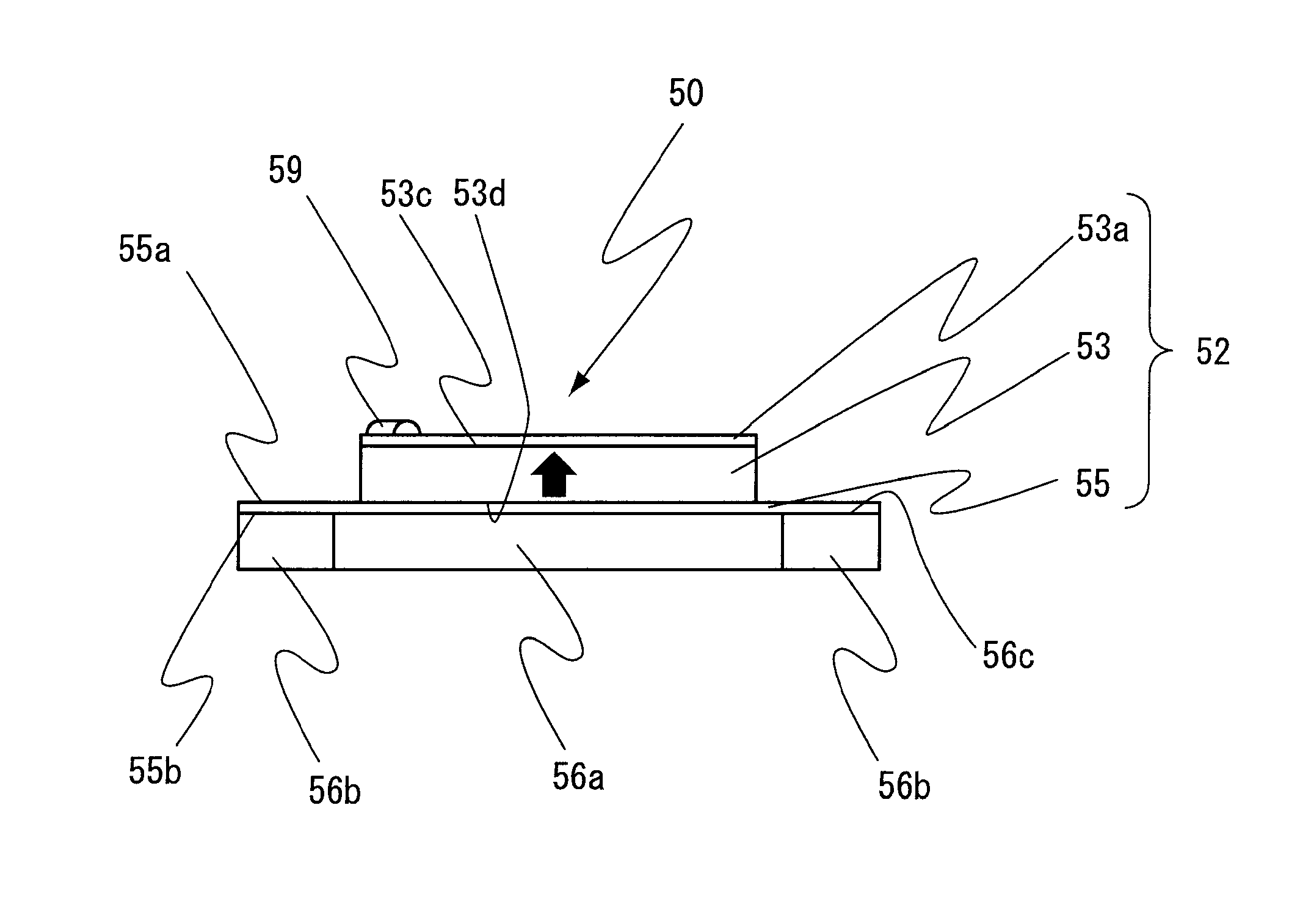

High sensitivity displacement measuring device using linear variable differential transformer

InactiveUS6489760B2Increased displacement amplificationReduce gapElectric signal transmission systemsElement comparisonLinear variable differential transformerMeasurement device

The present invention is intended to provide a ultra-precision high sensitivity displacement measuring device which has such a high resolution as to be able to make submicron measurement.According to the invention, there is provided a displacement measuring device with high resolution, comprising: an electromagnetic system (10) which forms a closed loop of magnetic blocks (17,19) and which houses primary coil bundles (11) and secondary coil bundles (13) for forming magnetic fields within said closed loop of magnetic blocks (17,19); plate springs (20) which include displacement input parts (21) and displacement output zones (24) fixed to the cores (14) having the secondary coils wound around them and which act to guide so that the displacement output zones (24) can output the displacement amplified in proportional to the displacement input to the displacement input parts (21); and a supporting mechanism (30) for supporting the displacement input parts (21) of said plate springs (20) so that the displacement may be input only in one axial direction.

Owner:KOREA ADVANCED INST OF SCI & TECH

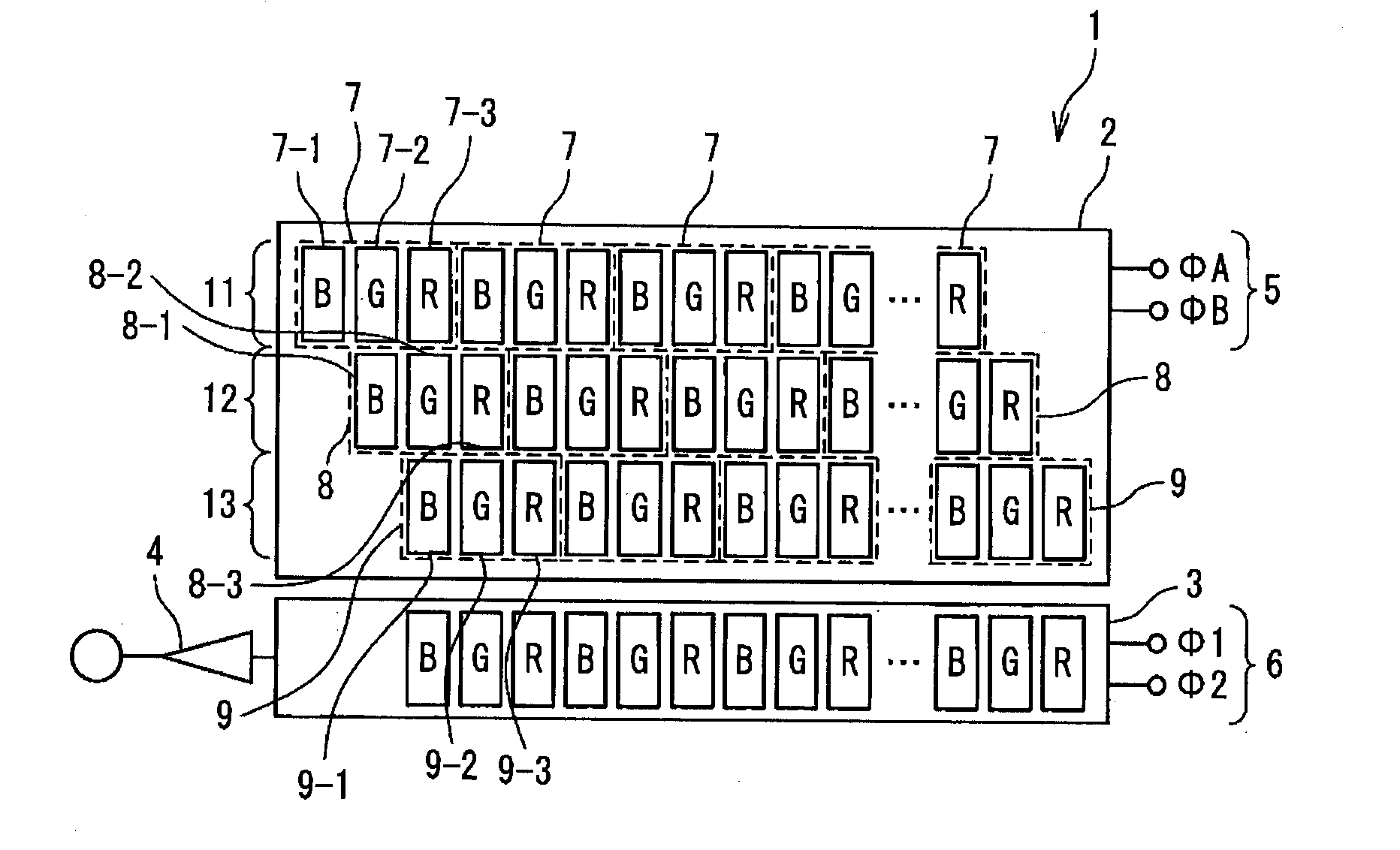

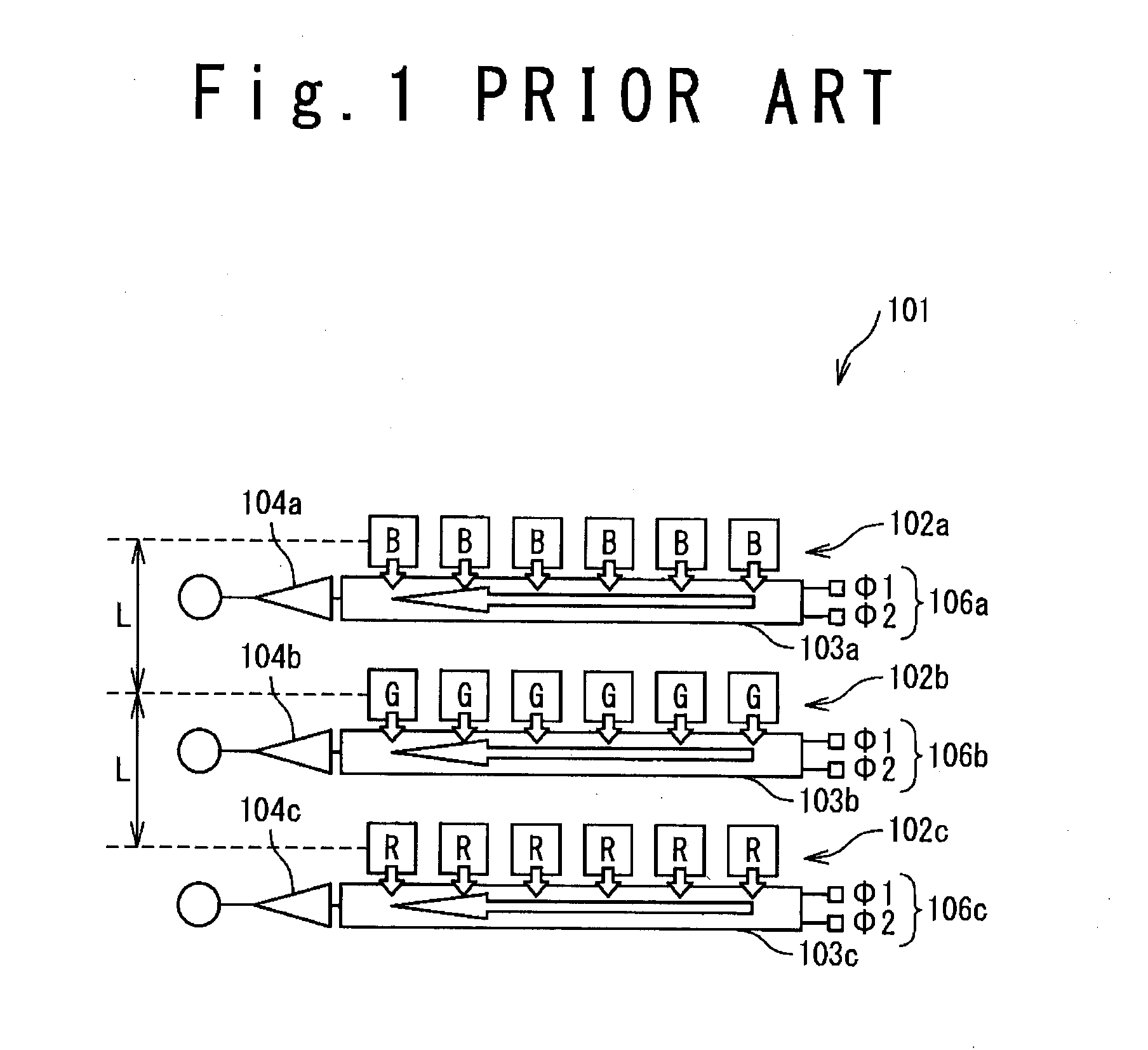

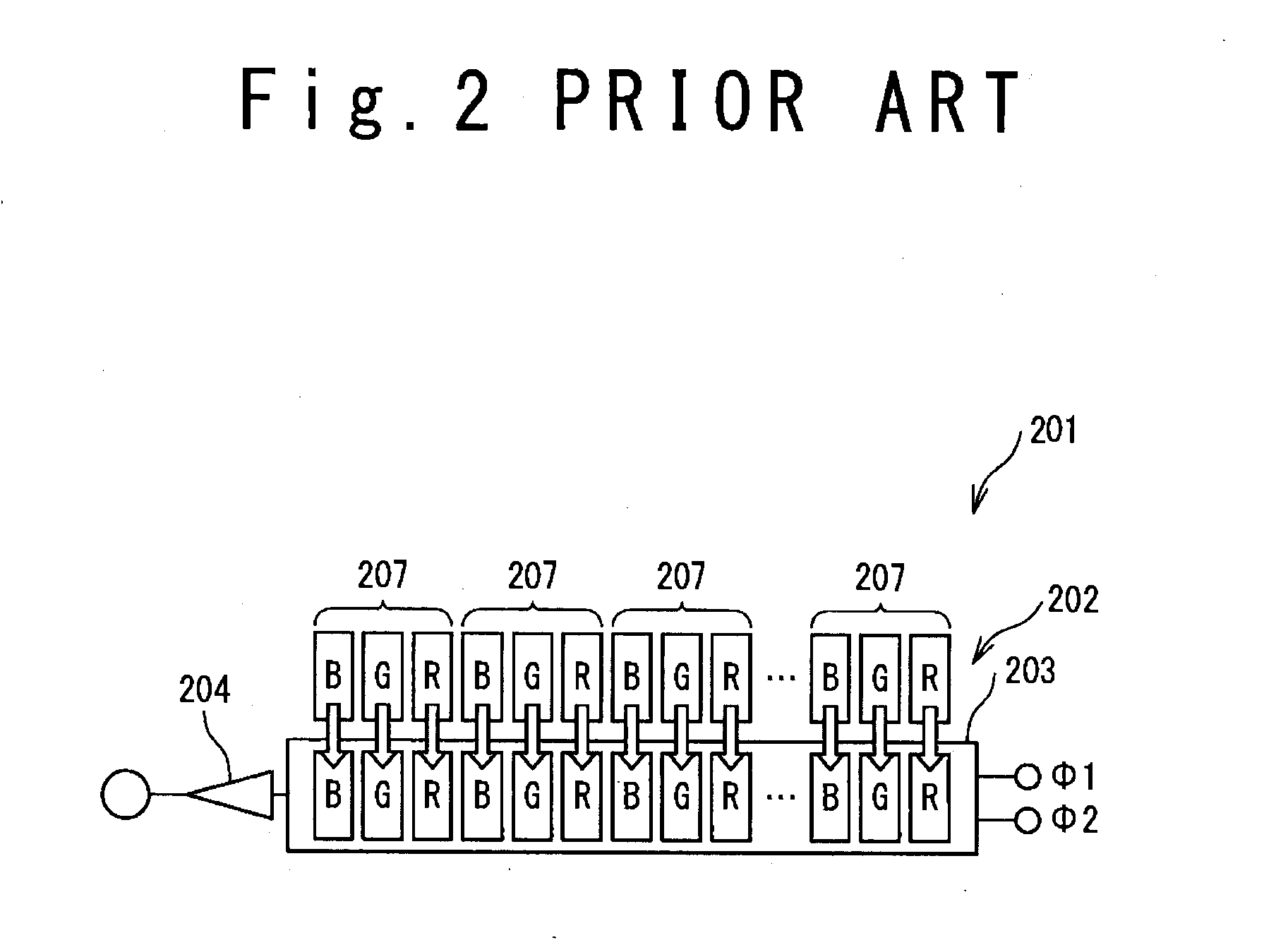

Color ccd linear image sensor

InactiveUS20100208116A1Improve output sensitivitySmall sensor sizeTelevision system detailsTelevision system scanning detailsImage sensor

A color CCD linear image sensor has: first basic pixels arranged in a first column and configured to accumulate first-column pixel charges; and second basic pixels arranged in a second column adjacent to the first column and configured to add accumulated charges to the first-column pixel charges to generate second-column pixel charges. The first basic pixels include a first-column first-color pixel, a first-column second-color pixel adjacent to the first-column first-color pixel, and a first-column third-color pixel adjacent to the first-column second-color pixel. The second basic pixels include a second-column first-color pixel, a second-column second-color pixel adjacent to the second-column first-color pixel, and a second-column third-color pixel adjacent to the second-column second-color pixel. The second-column first-color pixel is arranged adjacent to the first-column second-color pixel.

Owner:RENESAS ELECTRONICS CORP

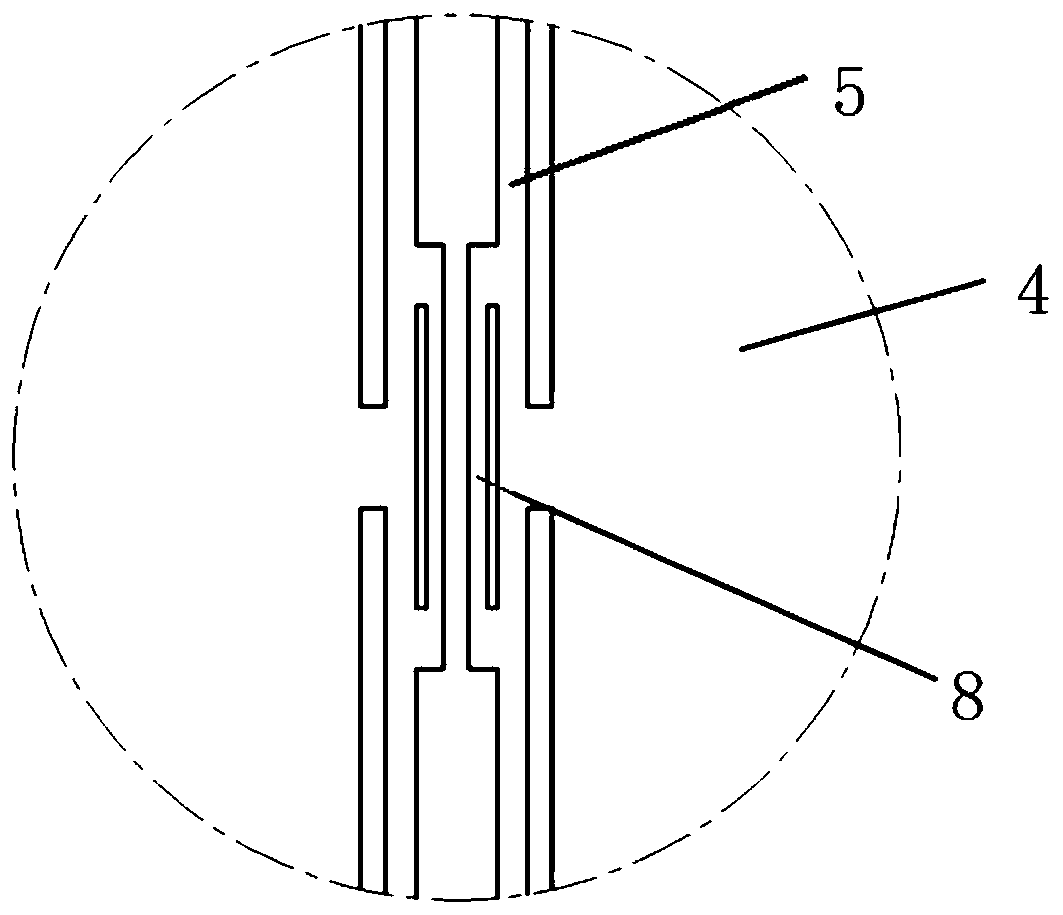

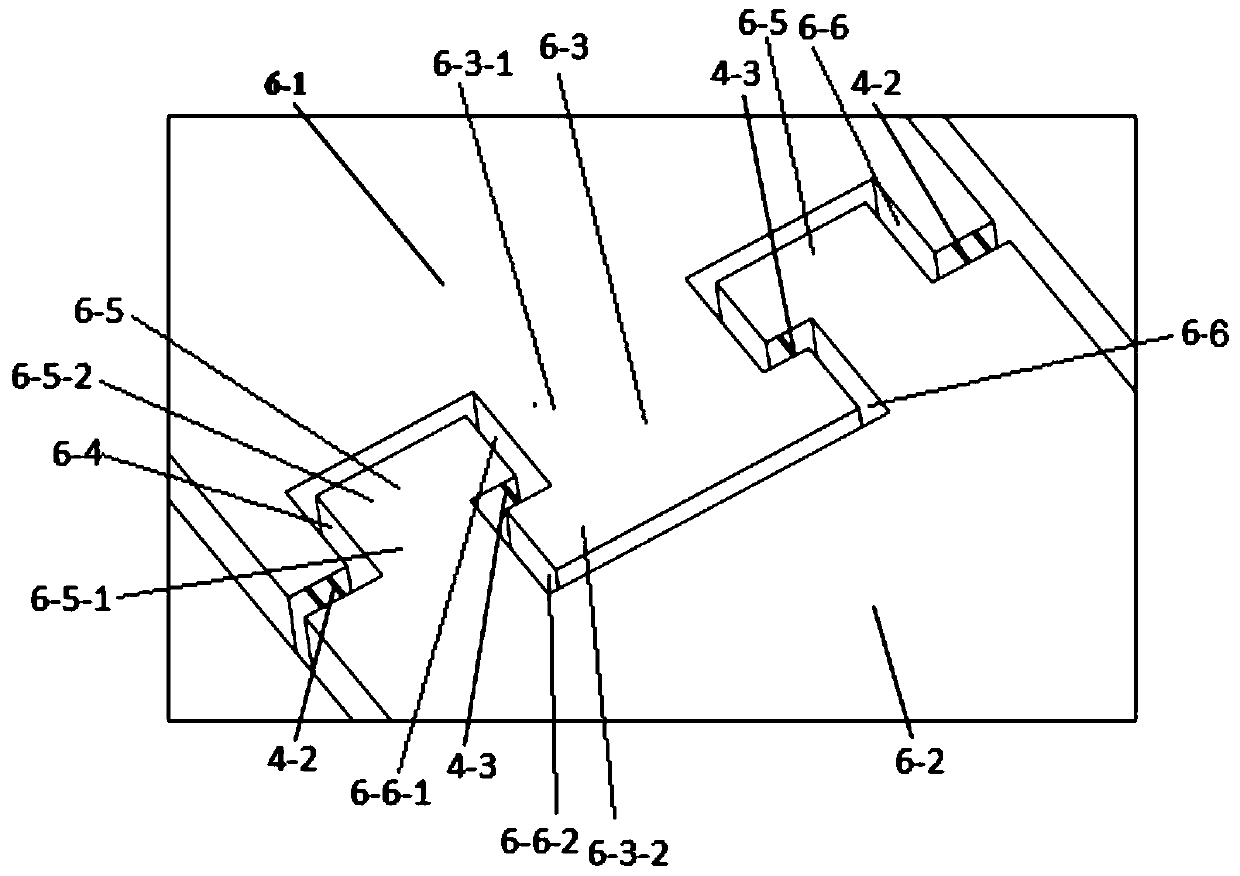

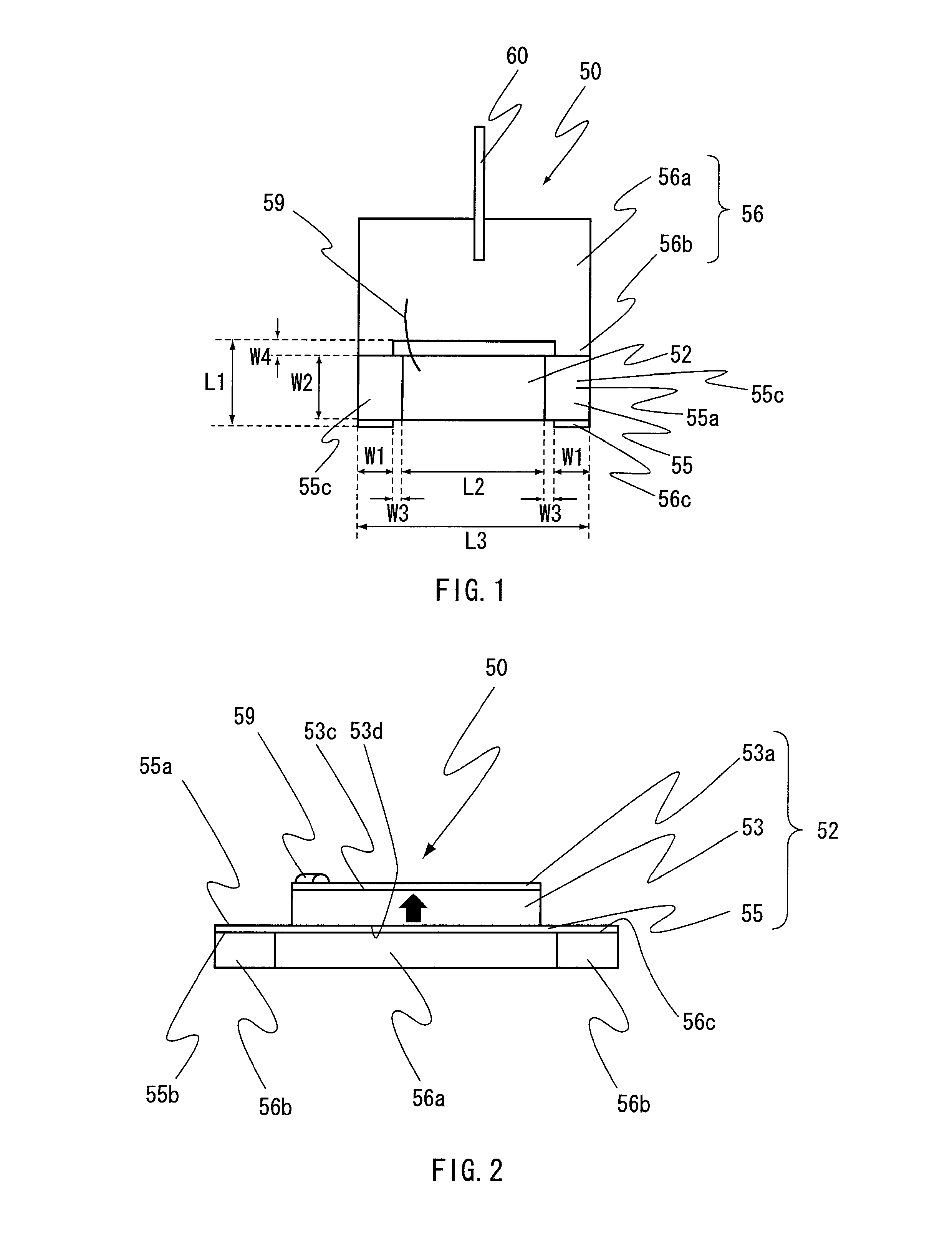

Differential silicon micro-resonant pressure sensor based on electrostatic excitation piezoresistance detection

ActiveCN111289156AImprove output sensitivityHigh precisionForce measurement using piezo-resistive materialsEngineeringMechanical engineering

The invention discloses a differential silicon micro-resonance type pressure sensor based on electrostatic excitation piezoresistance detection. The differential silicon micro-resonance type pressuresensor comprises a resonance beam, a coupling beam, a vibration pickup beam, a fixed electrode, a movable electrode, a mass block, a movable anchor point, a fixed anchor point and a silicon island, wherein the movable anchor point is fixedly connected with the pressure sensitive film through using the silicon island; when the pressure sensitive film is deformed by a load, the movable anchor pointconnected with the pressure sensitive film is driven, then the movable anchor point drives the resonance beam to deform, such that the internal stress of the resonance beam is changed, the vibration frequency of the resonator is changed, the vibration frequency of the resonance beam is measured by means of a piezoresistor on the vibration pickup beam, and the vibration pickup beam and the couplingbeam adopt a special design method, so that the vibration pickup beam generates straight pulling and straight pressing acting force when the resonator is in a working mode, and the amplitude of the resonance beam can be linearly output through using a Wheatstone bridge.

Owner:XI AN JIAOTONG UNIV

Capacitive pressure sensor and method therefor

ActiveUS7448277B2Increased pressure sensitivityIncrease in sizeElectrolytic capacitorsCapacitor with electrode distance variationCapacitive pressure sensorCapacitor

Owner:EVIGIA SYST

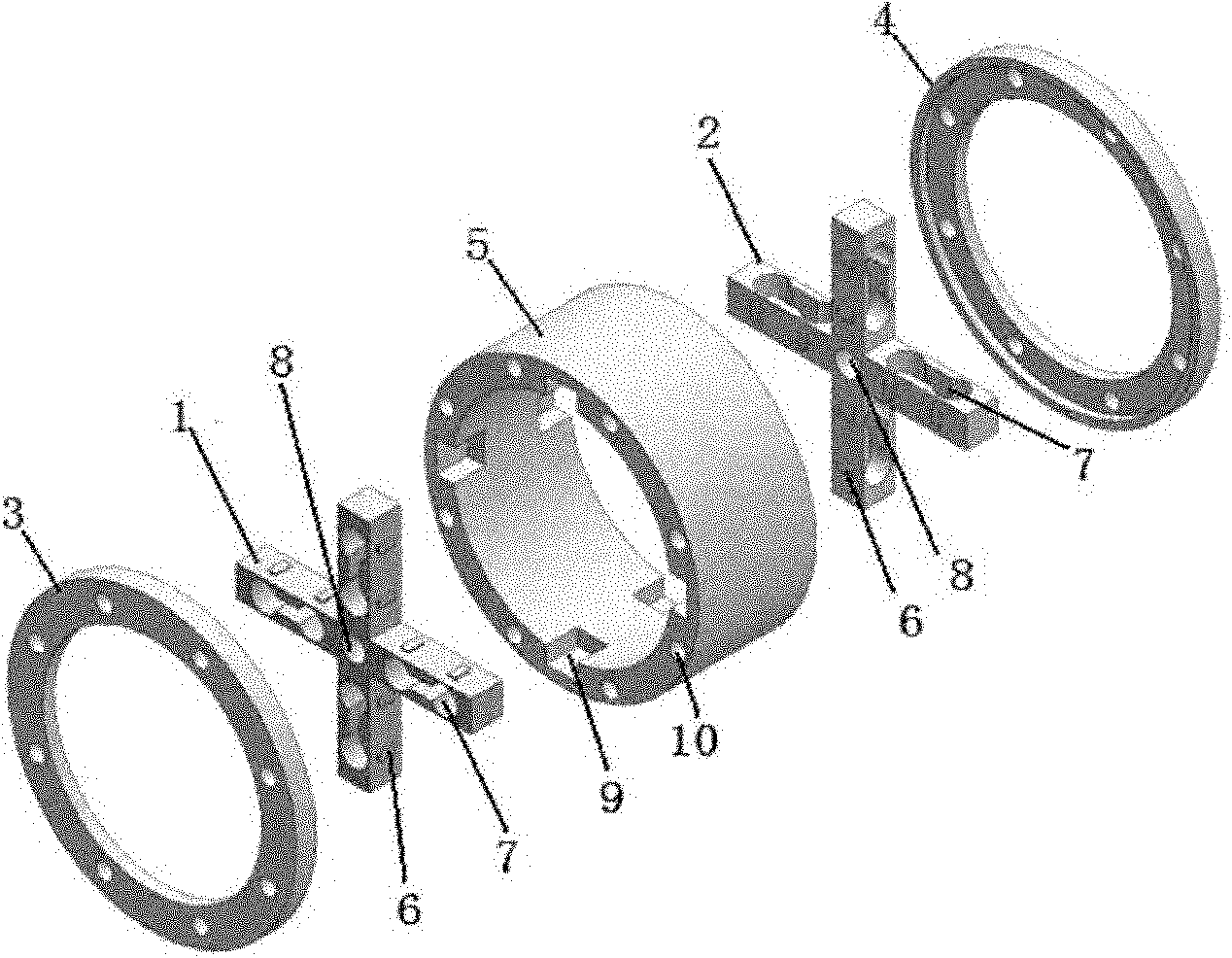

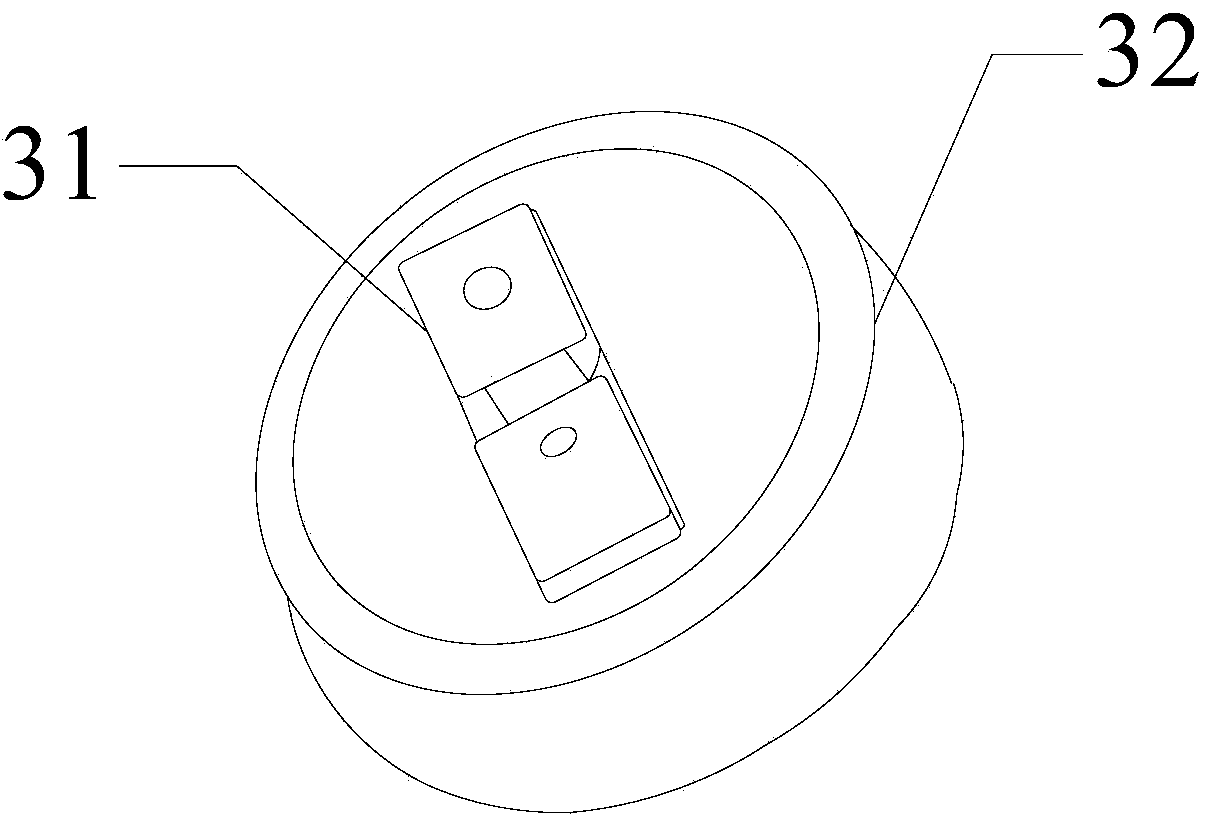

Passive piezoelectric geophone movement, and passive piezoelectric detector based on the same

ActiveCN105607116AHigh sensitivityImprove signal-to-noise ratioSeismic signal receiversGeophoneSignal-to-noise ratio (imaging)

The invention discloses a passive piezoelectric geophone movement, and a passive piezoelectric detector based on the same. The passive piezoelectric geophone movement includes a ceramic mounting ring, wherein a ceramic chip each is arranged on the upper and lower surfaces of the ceramic mounting ring respectively; each ceramic chip is double-sided positive and negative bonded ceramic on a substrate; a medium hole is formed in the substrate; a mass body is fixed on the upper ceramic chip through a screw; the lower ceramic chip is fastened on a pedestal through a screw; each screw is provided with an insulating bush which is used for preventing occurrence of short circuit between the screw and the substrate of the ceramic chip; an internal housing is rotationally arranged on the pedestal; a round hole is formed above the internal housing and is used for threading out a positive and negative pole lead; and the positive and negative pole lead of each ceramic chip is threaded out from the round hole above the internal housing. The passive piezoelectric geophone movement, and the passive piezoelectric detector based on the same have the characteristics of being high in sensitivity, being effective in frequency band width and being high in signal to noise ratio.

Owner:XIAN LUZHOU INTELLIGENT SENSING TECH CO LTD

Magnetoelectric laminated material current sensing device based on magnetic convergence effect

ActiveCN110333378ASatisfy the optimal bias magnetic fieldImprove output sensitivityCurrent measurements onlyVoltage/current isolationResonanceLinearity

The invention provides a magnetoelectric laminated material current sensing device based on a magnetic convergence effect. The device comprises a protective shell, a fixed base, a magnetic convergencesubstructure arranged on the fixed base, a permanent magnet arranged at the bottom of the magnetic convergence substructure, a mass block and a magnetoelectric laminated material which are respectively arranged above the magnetic convergence substructure, and a current carrying conductor arranged on the lower surface of the magnetoelectric laminated material. By means of the design, the problemsthat the sensitivity and linearity of an existing sensing device are low, the sensing device is complex in structure and difficult to install, a direct-current bias magnetic field is a fixed value andis difficult to adjust, and the structural resonance frequency cannot be adjusted are solved. The device is simple in structure and high in reliability, the structural resonance frequency is adjustedto be close to the current frequency, the larger output sensitivity is obtained, the direct-current bias magnetic field can be adjusted and the optimal bias magnetic fields of different magnetoelectric materials can be met, and furthermore, the resonance frequency can be adjusted, and the larger sensitivity is achieved when the currents at different frequencies are measured.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +2

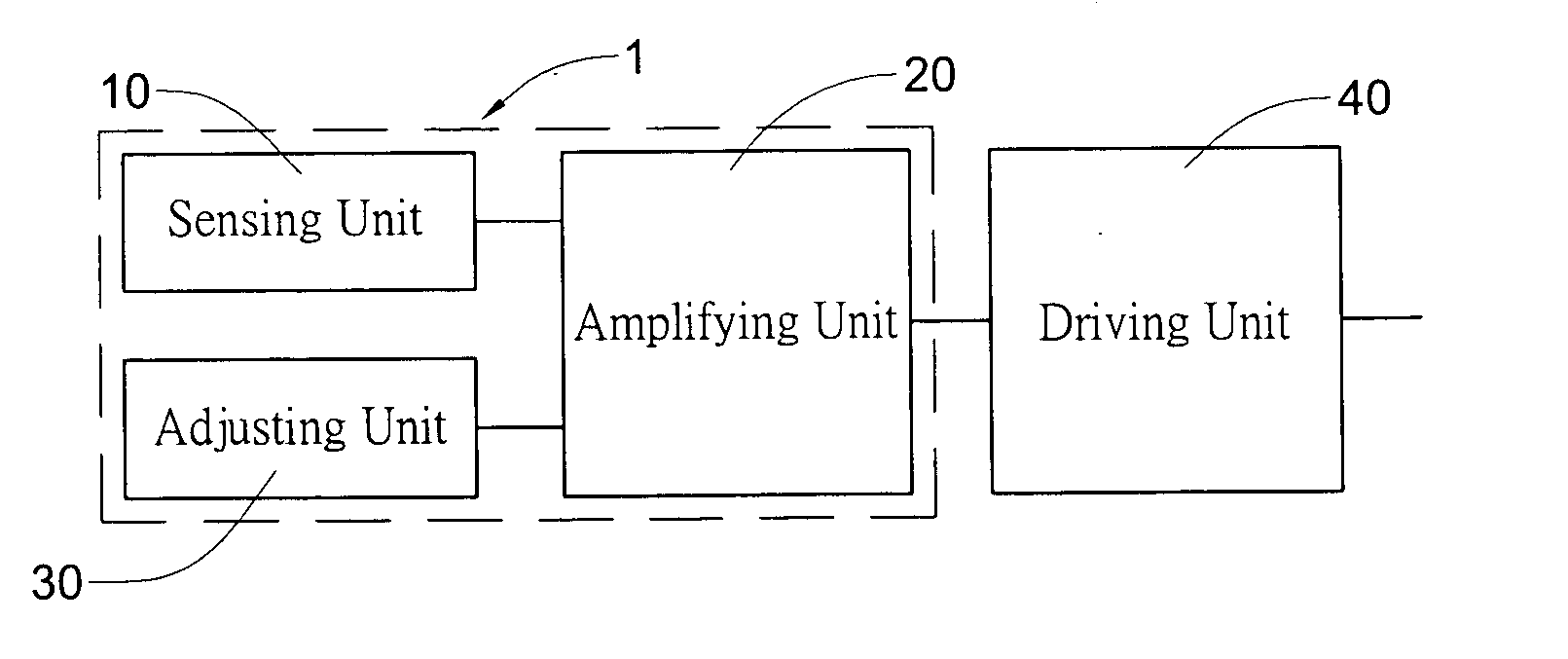

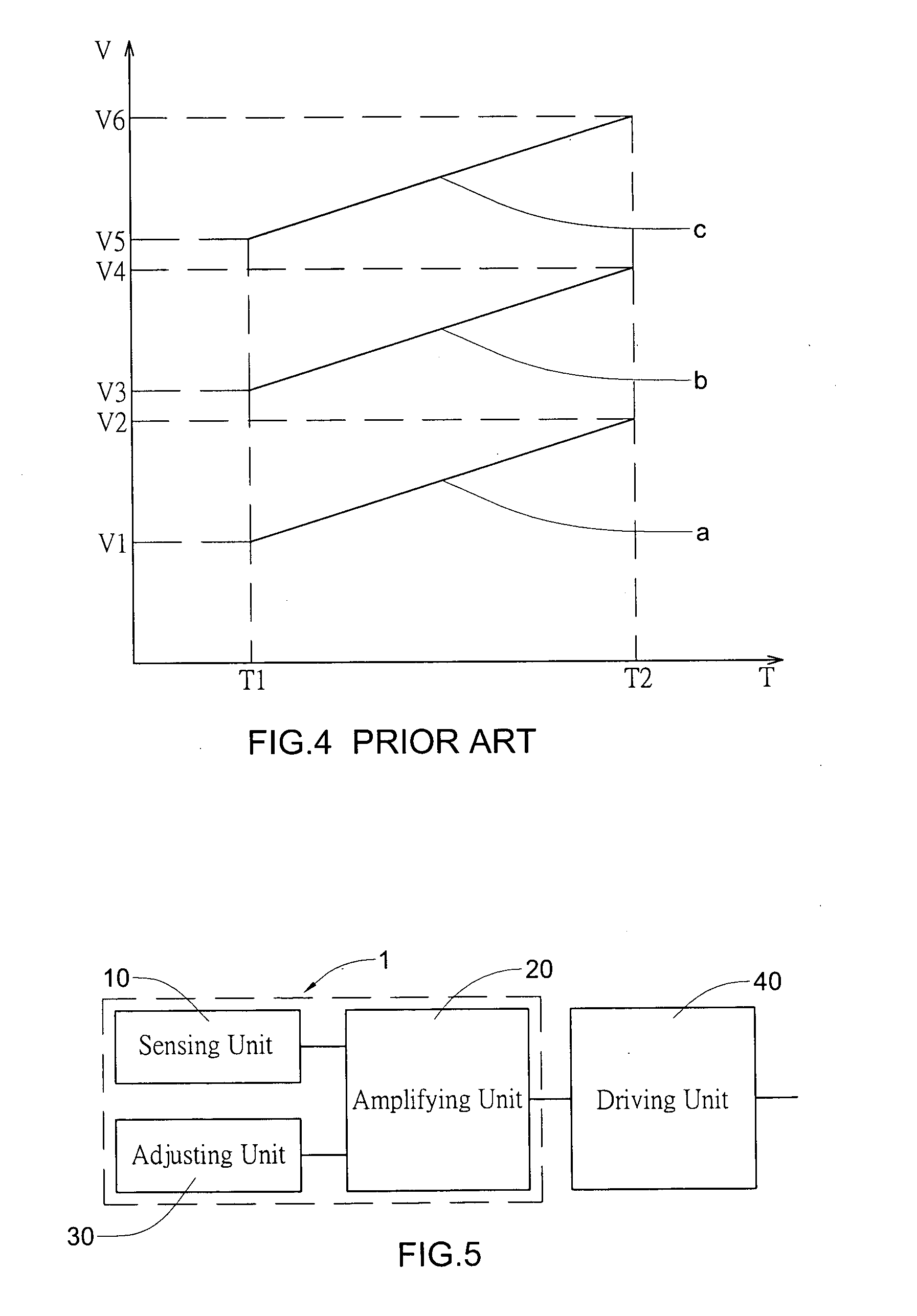

Circuit structure capable of adjusting gradient of output to temperature variation

InactiveUS20050212598A1Easy to changeImprove output sensitivityElectric motor controlTemperatue controlEngineeringEnvironmental temperature

A circuit structure capable of adjusting gradient of output to temperature variation includes at least a sensing unit for detecting ambient temperature variation and generating a sensing signal, an amplifying unit connected to the sensing unit for increasing a level of the sensing signal, and an adjusting unit connected to the amplifying unit for increasing or decreasing an amplification ratio of the amplifying unit, so as to change a gradient of an output of the amplifying unit to temperature variation.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

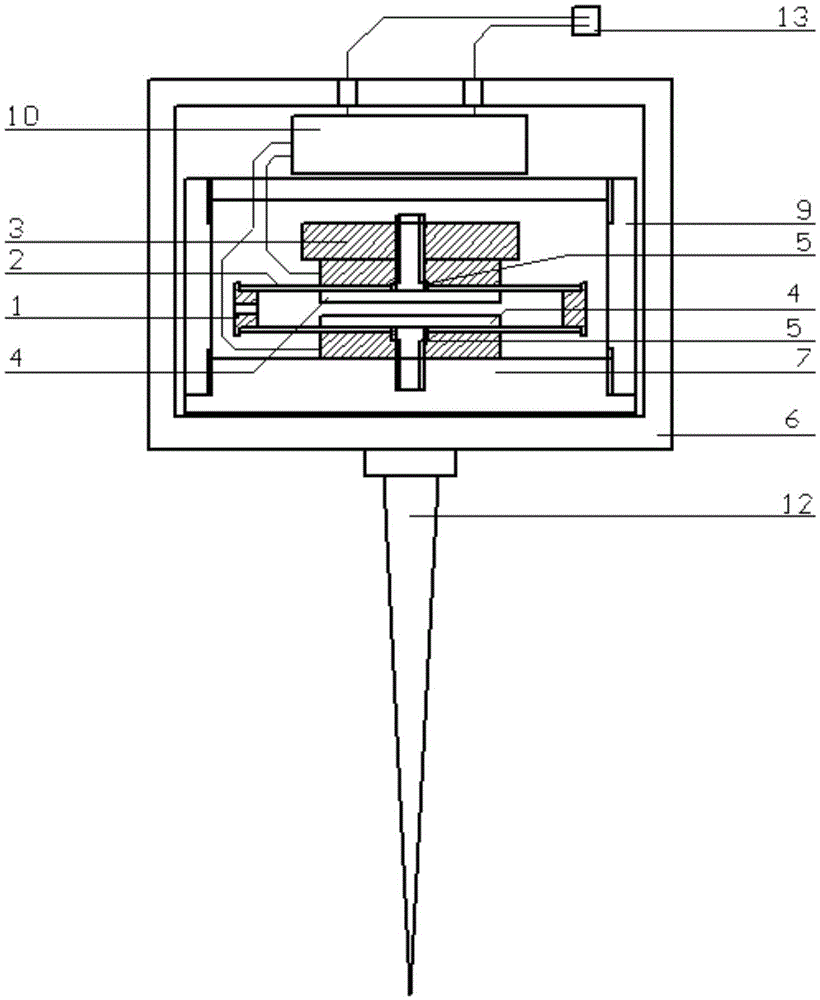

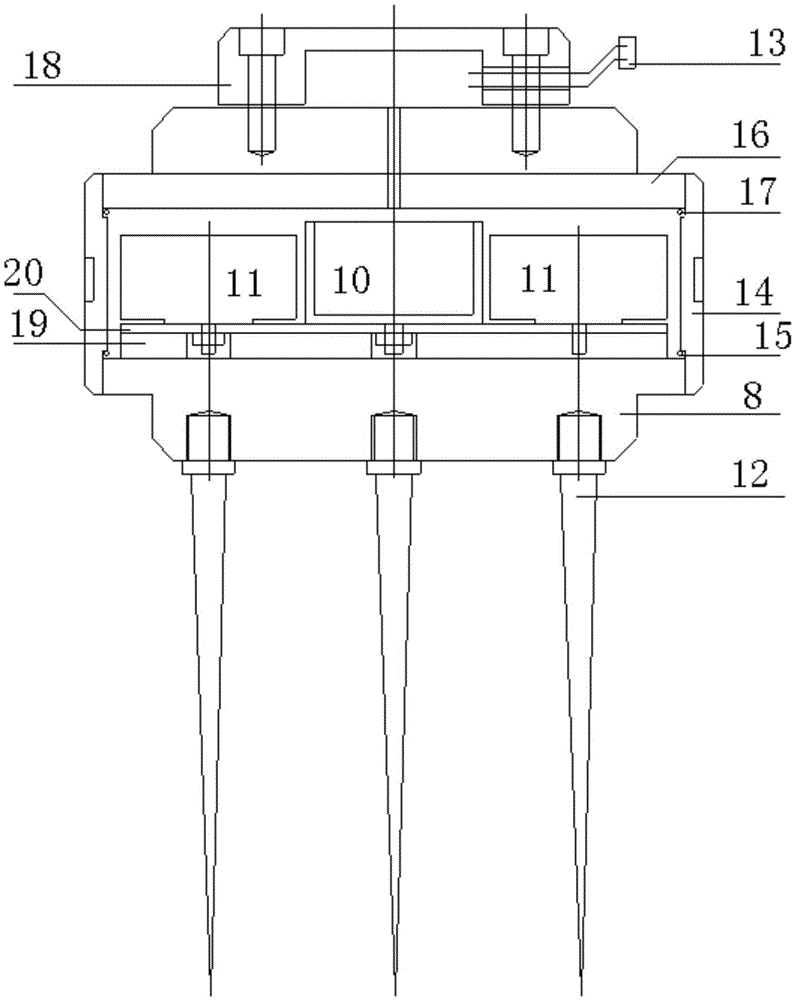

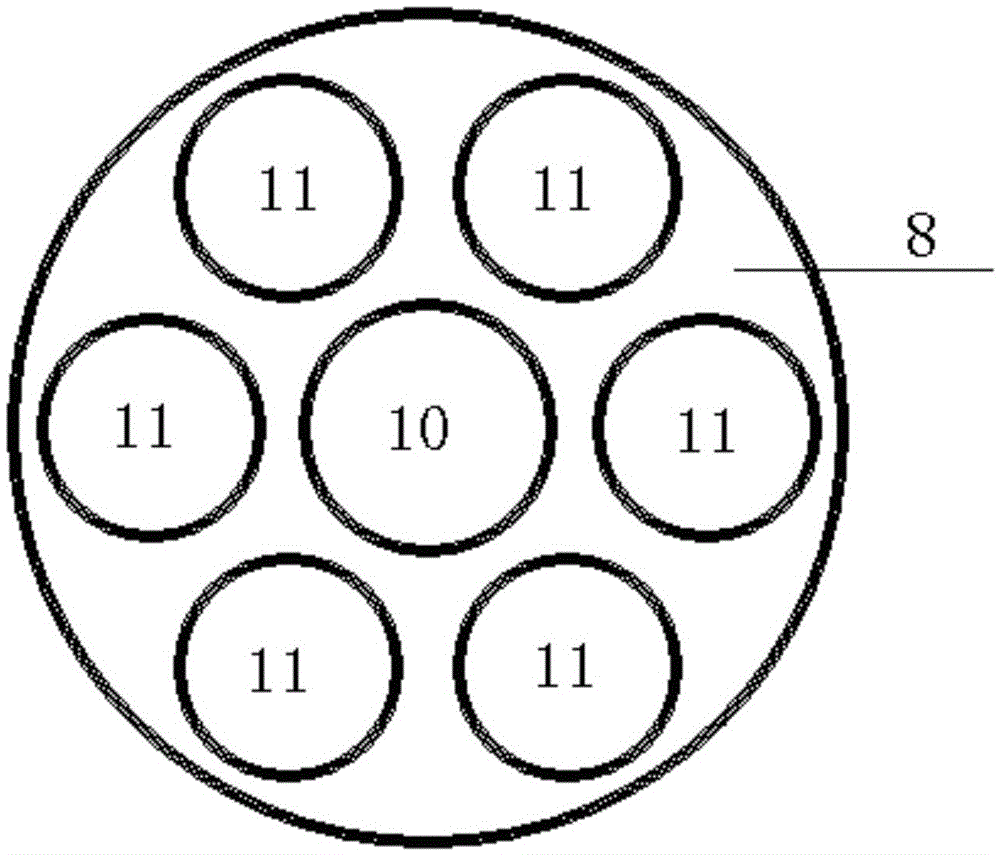

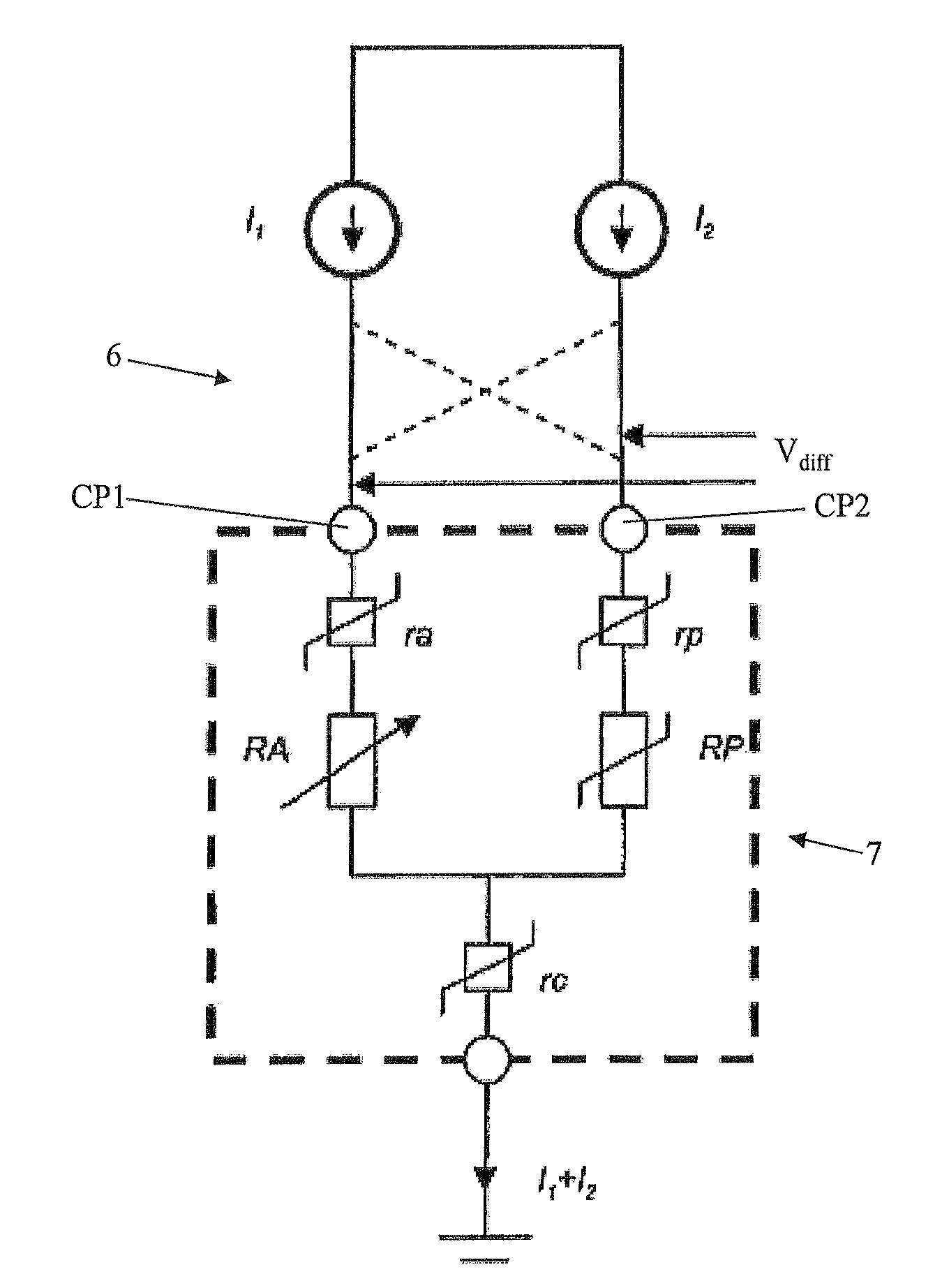

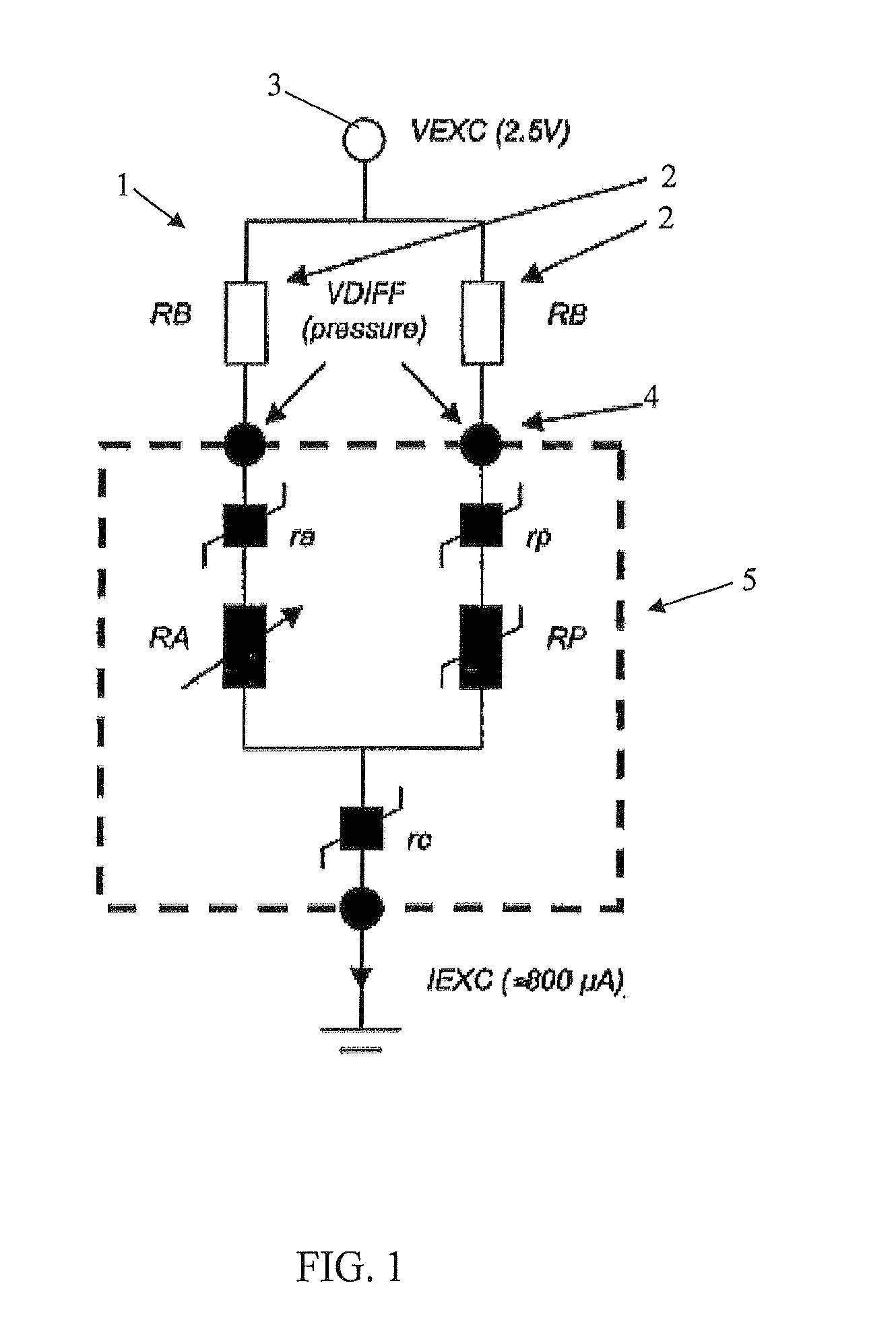

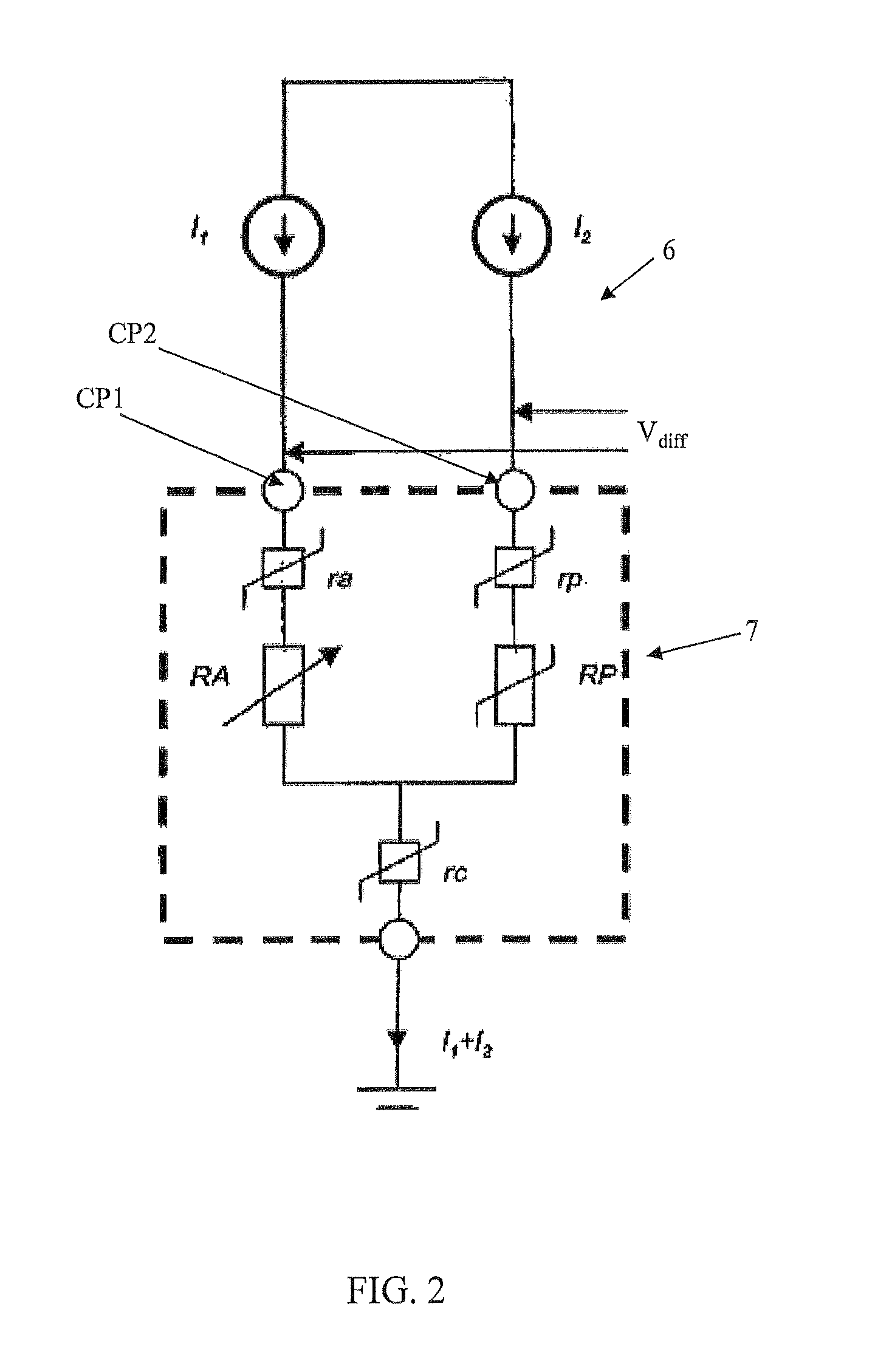

Interface unit, measurement system and a method in an interface unit

ActiveUS20130225941A1Reduce physical sizeHigh measurement accuracyElectrotherapyGuide wiresEngineeringLiving body

The present invention relates to an extracorporeale interface unit (8), for an intravascular measurement system for measuring a physiological, or other, variable in a living body, being adapted to generate a sensor signal in response of said variable. The interface unit (8) comprises a sensor interface circuitry (6) adapted to interface a sensor wire configured to be inserted into the living body and provided with one or many sensor element(s) at its distal region. The sensor interface circuitry (6) further comprises a measurement unit (9) adapted to generate the measured data of the variable as a sensor signal. The sensor interface circuitry (6) comprises two current source units (CSU1, CSU2) adapted to energize the sensor element(s) via at least two connection points (CP1, CP2, . . . CPn), and a switching unit (10), wherein the switching unit (10) is adapted to alternately switch connection between the current source units (CSU1, CSU2) and at least two of the connection points (CP1, CP2, . . . CPn), using a preset switching frequency having essentially the same connection time period (Tc) for each connection. The measurement unit (9) is adapted to determine a sensor variable value (Vdiff) related to the variable at two of the connection points (CP1, CP2, . . . CPn). The present invention further relates to a measurement system (12) comprising said extracorporeale interface unit (8) and a method in said interface unit.

Owner:ST JUDE MEDICAL COORDINATION CENT

Strain sensor for measuring structural deflection

InactiveCN102323022ALow sensitivity to changesImprove signal-to-noise ratioElasticity measurementBiochemical engineeringSelf locking

The invention discloses a strain sensor for measuring structural deflection. The strain sensor is fixed on the surface wall of a tested structure and comprises an elastic body, a strain gauge and installation brackets, wherein the strain gauge is arranged in the elastic body; the elastic body is provided with installation holes distributed on both sides of the strain gauge; one end of each installation bracket is welded together with the tested structure, and the other end of each installation bracket passes through each installation hole and is fixed in each installation hole through a self-locking nut; the installation brackets and the installation holes correspond to each other one by one; and the elastic body is fixed on the neutral surface of the tested structure through the installation brackets. By adopting the strain sensor for measuring the structural deflection, the technical defect that a sensor in the prior art cannot be used for detecting a beam in real time is overcome, the measuring accuracy of the sensor can be increased simultaneously, and the service life of the sensor is prolonged.

Owner:重庆大唐科技股份有限公司

High sensitivity displacement measuring device using linear variable differential transformer

InactiveUS20020030486A1Increased displacement amplificationReduce gapElectric signal transmission systemsElement comparisonLinear variable differential transformerMeasurement device

The present invention is intended to provide a ultra-precision high sensitivity displacement measuring device which has such a high resolution as to be able to make submicron measurement. According to the invention, there is provided a displacement measuring device with high resolution, comprising: an electromagnetic system(10) which forms a closed loop of magnetic blocks(17,19) and which houses primary coil bundles(11) and secondary coil bundles(13) for forming magnetic fields within said closed loop of magnetic blocks(17,19); plate springs(20) which include displacement input parts(21) and displacement output zones(24) fixed to the cores(14) having the secondary coils wound around them and which act to guide so that the displacement output zones(24) can output the displacement amplified in proportional to the displacement input to the displacement input parts(21); and a supporting mechanism(30) for supporting the displacement input parts(21) of said plate springs(20) so that the displacement may be input only in one axial direction. (FIG. 2).

Owner:KOREA ADVANCED INST OF SCI & TECH

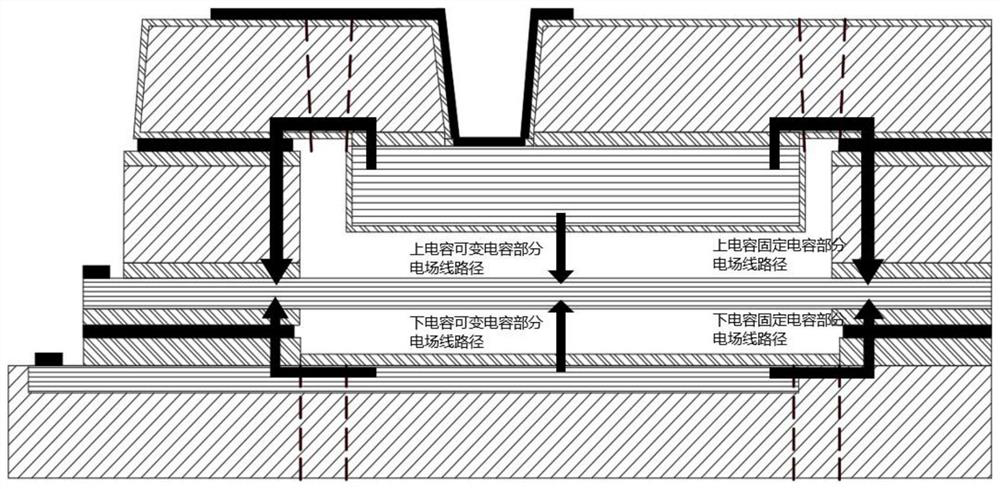

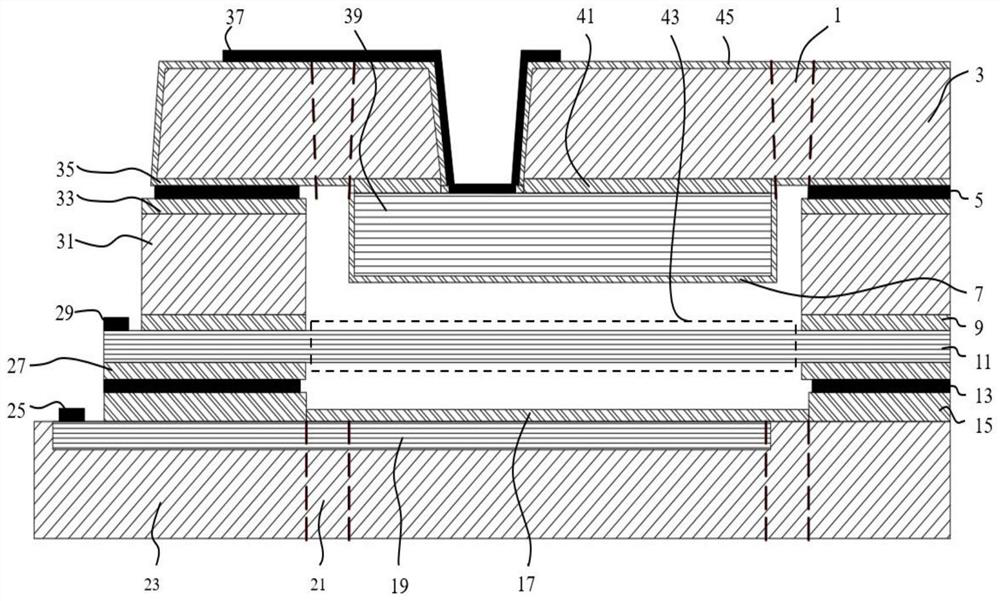

Capacitive differential pressure sensor, manufacturing method and application thereof

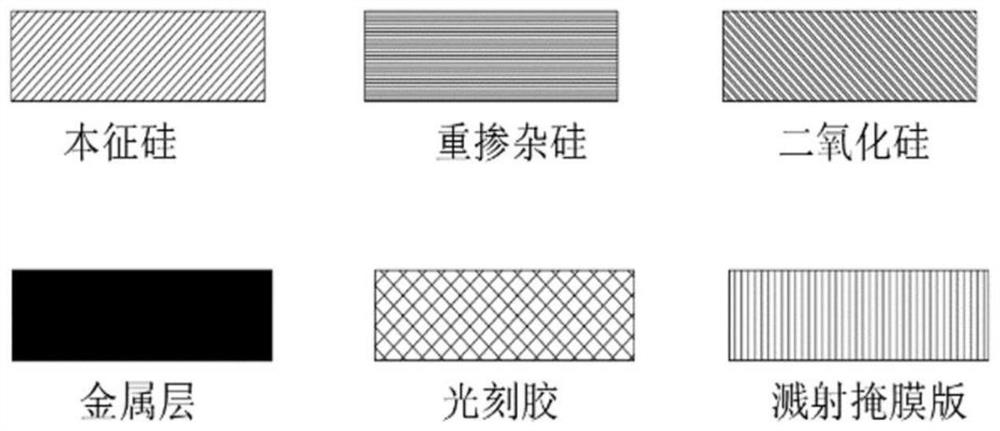

ActiveCN114459666AHigh resistivityLow dielectric constantTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsImage resolution

According to the differential pressure sensor, the preparation method and the application thereof, a three-layer silicon wafer bonding mode is adopted, an upper layer structure and a middle layer structure both adopt SOI wafers, and a lower layer structure adopts a graphical doped intrinsic silicon wafer; lead bonding pads of the electrodes are positioned on three steps on one side of the sensor; the peripheries of the upper electrode and the lower electrode are provided with approximately annular through holes. According to the sensor, the path of the electric field line of the fixed capacitor part is prolonged, so that the fixed capacitance in a capacitance signal output by the upper capacitor is reduced; the lower-layer structure adopts intrinsic silicon, and only the lower-layer electrode and the lead part are doped and can conduct electricity. By picking up the variable quantity of the two capacitors, the measurement of the pressure difference of fluid in the two different cavities is realized; the output sensitivity, the resolution ratio and the linearity of the sensor are all improved; external lead welding spots of the sensor are arranged at the three-layer step, an external circuit is electrically connected with a sensor lead at the three-layer step, and integration and packaging of the sensor are facilitated.

Owner:BEIHANG UNIV

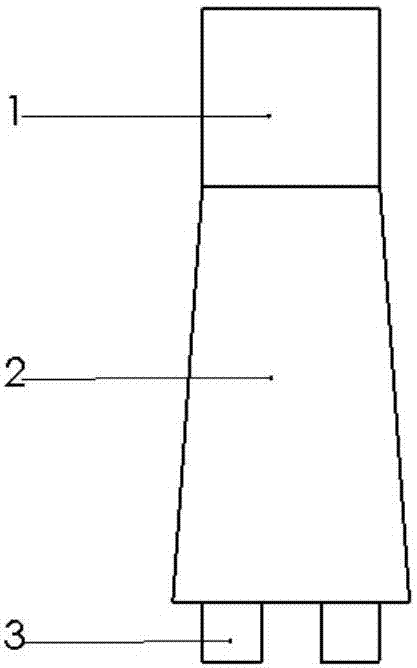

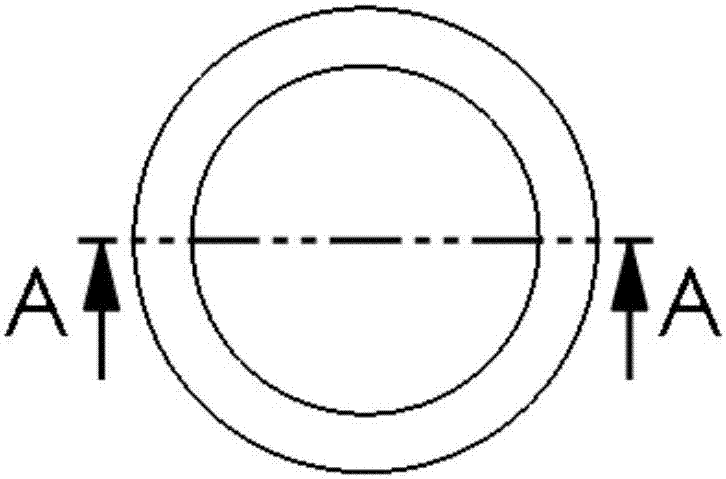

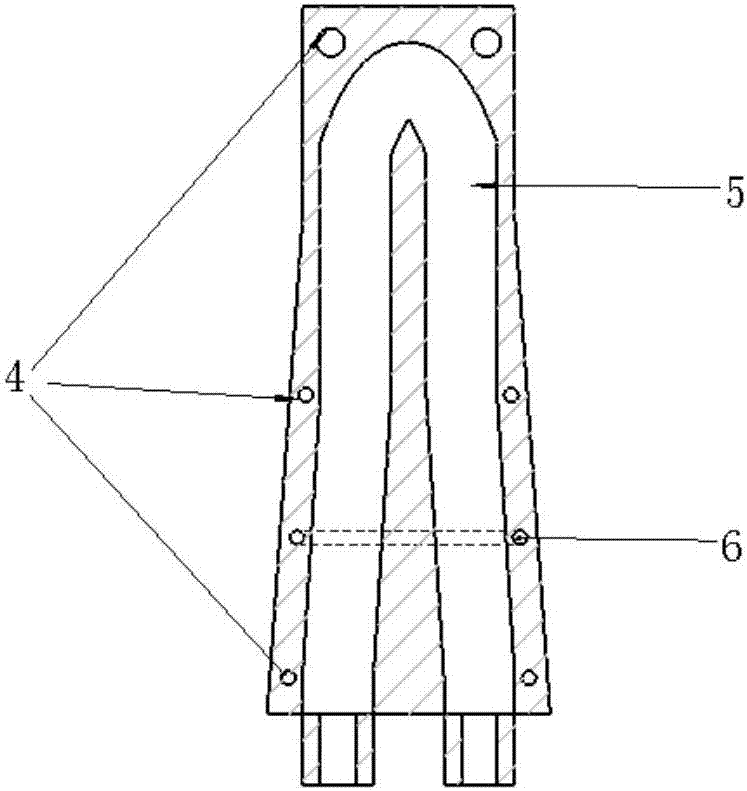

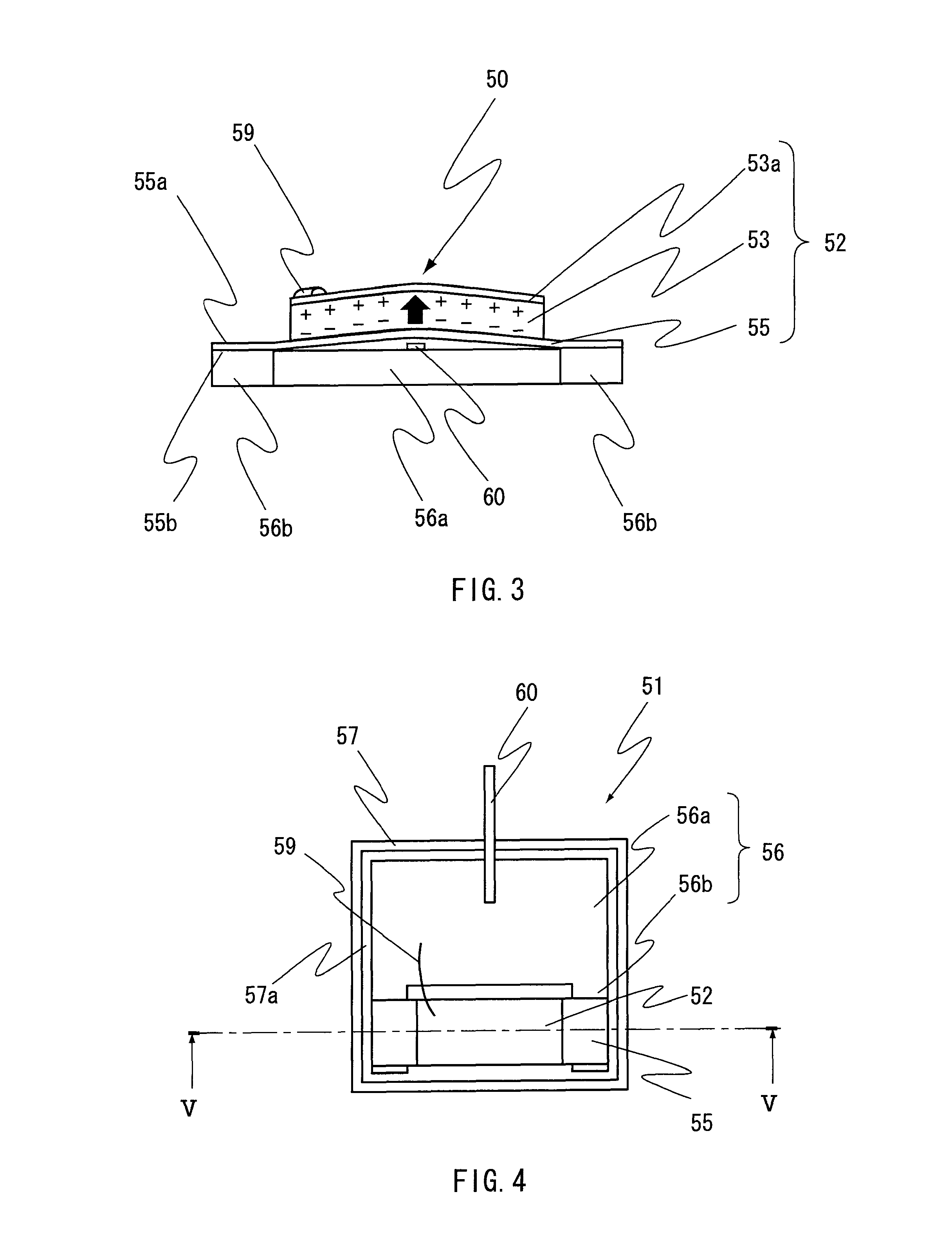

High-sensitivity film thermocouple sensor chip and making method thereof

ActiveCN106908163AMeet the requirements of fast heat dissipationHigh thermal conductivityThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesAlloy

The invention discloses a high-sensitivity film thermocouple sensor chip and a making method thereof. The high-sensitivity film thermocouple sensor chip comprises a shell. The shell is internally provided with a cavity for placing an alloy film and an annular hole for placing graphene. The annular hole is at the periphery of the cavity. The cavity is internally provided with an alloy film which is made into a film thermocouple. The annular hole is internally provided with graphene. The shell includes three sections: a test probe, a middle circular truncated cone, and a lead end. By designing a new sensor structure, temperature signals can be measured for a long time in a dynamic high temperature field. Through forced heat transfer, a large thermal gradient is formed between the cold end and the hot end of the thermocouple film, and the sensitivity of the film thermocouple is enhanced. The sensor chip has the characteristics of high sensitivity, small size, resistance to high temperature, anti-oxidation, high Seebeck coefficient, and applicability to dynamic test. The problem in the prior art that the film thermocouple is of low sensitivity due to too high temperature at the cold end in a dynamic high temperature field test environment is solved.

Owner:XI AN JIAOTONG UNIV

Locating Device

ActiveUS20070290671A1Easy to detectImprove displayabilityCurrent/voltage measurementMagnetic property measurementsHand heldEngineering

A locating device, in particular a hand-held locating device, for detecting objects enclosed in a medium, including an output unit for displaying at least one output variable correlated with a measuring signal of at least one sensor of the locating device, the output unit having a first dynamic range for displaying the output variable correlated with the measuring signal. At least one further dynamic range having a changed sensitivity compared to the first dynamic range is displayable via the display unit.

Owner:ROBERT BOSCH GMBH

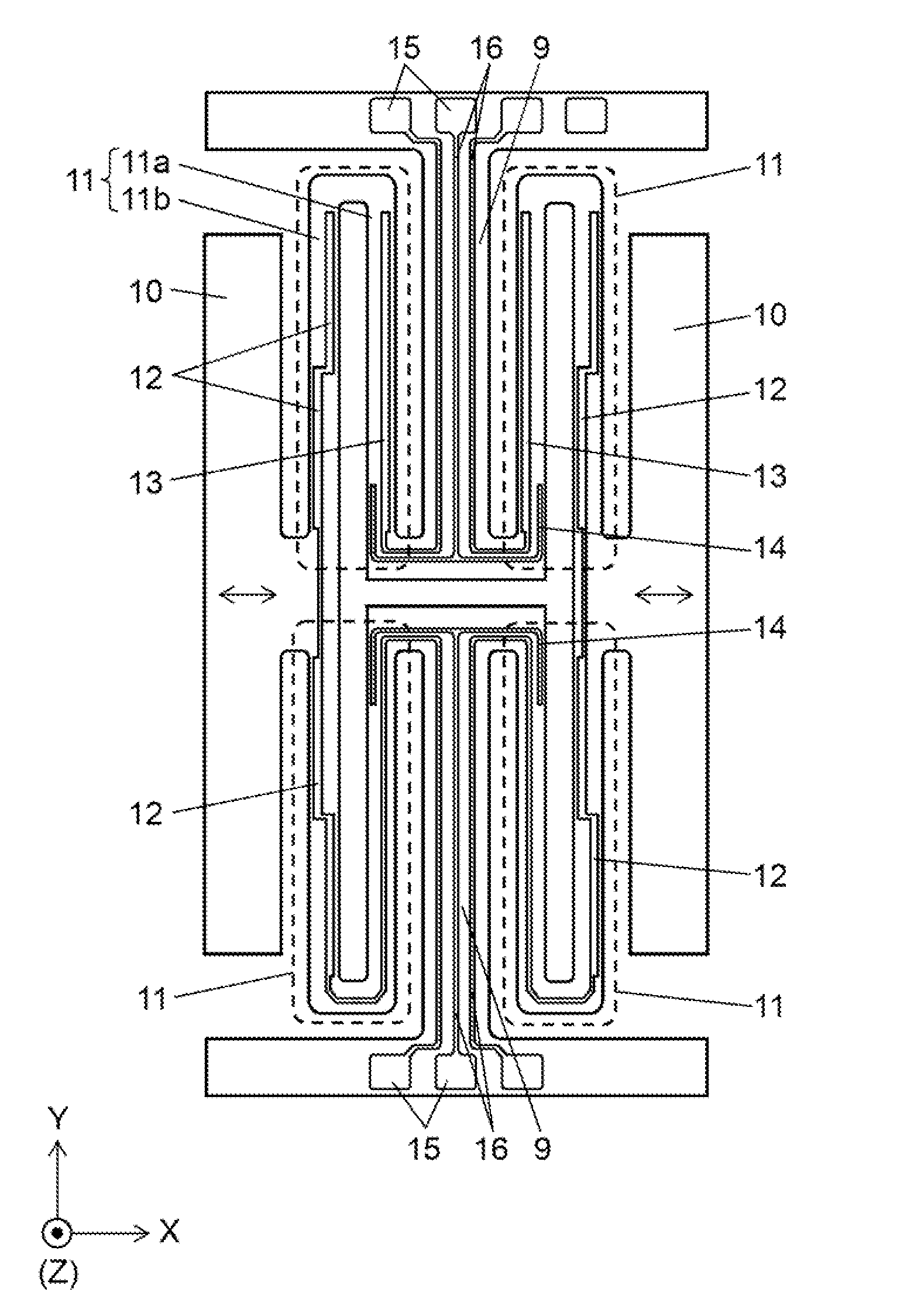

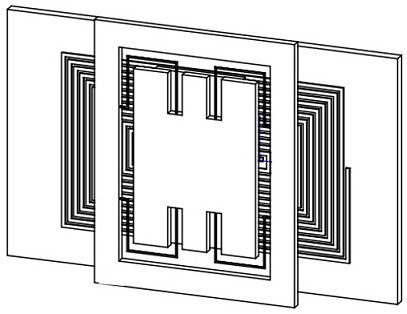

Angular velocity sensor element, angular velocity sensor and angular velocity sensor unit both using angular velocity sensor element, and signal detecting method for angular velocity sensor unit

ActiveUS8561467B2Improve detection levelImprove accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocity

The angular velocity sensor of the present invention has one end connected to holding section and the other end connected to weighting section. According to the angular velocity sensor, driving arm has a dog-leg structure of arms extending in a direction perpendicular to a connecting direction of holding section and weighting section.

Owner:PANASONIC CORP

Differential MEMS accelerometer based on tunneling magneto-resistor array

InactiveCN112858720AHigh precisionHigh sensitivityAcceleration measurement using interia forcesAccelerometerEngineering

The invention discloses a differential MEMS accelerometer based on a tunneling magneto-resistor array. The differential MEMS accelerometer comprises a magnetic field generation and detection part on a lower layer, a magnetic field modulation part on an upper layer and an installation frame where the magnetic field generation and detection part and the magnetic field modulation part are located, the magnetic field generation and detection part comprises a magnet exciting coil, a tunneling magnetoresistor and a magnetic field collector, and a constant-intensity magnetic field can be generated and the change of the magnetic field influenced by a modulator can be detected; and a main body of the upper-layer magnetic field modulation part is a mass-flexible structure, and a magnetic field regulator is arranged on the lower surface of a mass block and can modulate a magnetic field. In addition, the accelerometer is also provided with a differential detection structure, so that the sensitivity can be improved, and the temperature noise can be reduced. According to the invention, an acceleration-magnetic field intensity-resistance signal conversion mode is adopted, the high change rate characteristic of the tunneling magnetoresistance is fully utilized to improve the acceleration detection efficiency, and meanwhile, an integration method is adopted in the process, so that the method has incomparable advantages in the aspects of precision and volume, and can be widely applied to the fields of high-precision inertial navigation and military industry.

Owner:SOUTHEAST UNIV

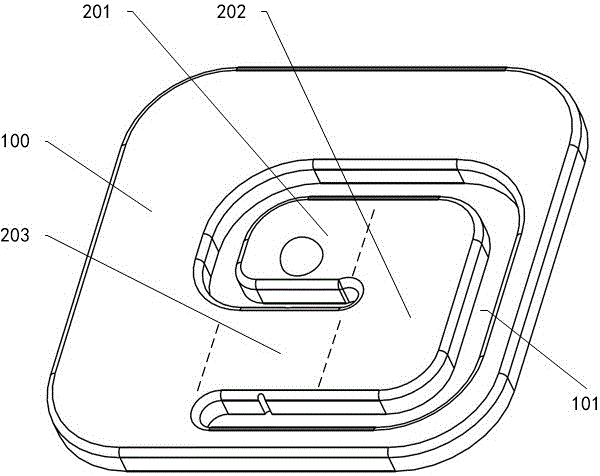

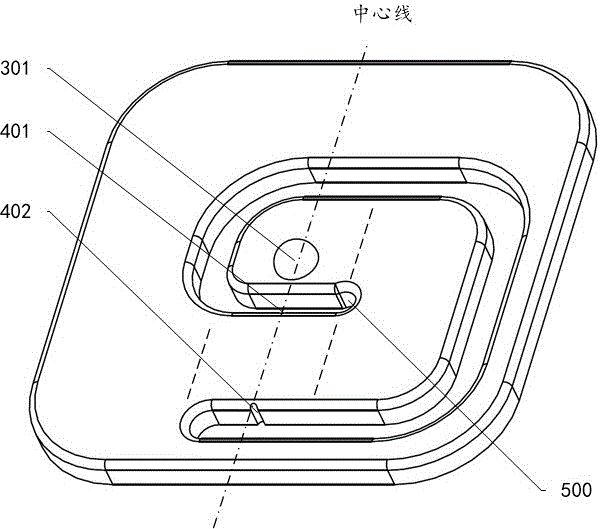

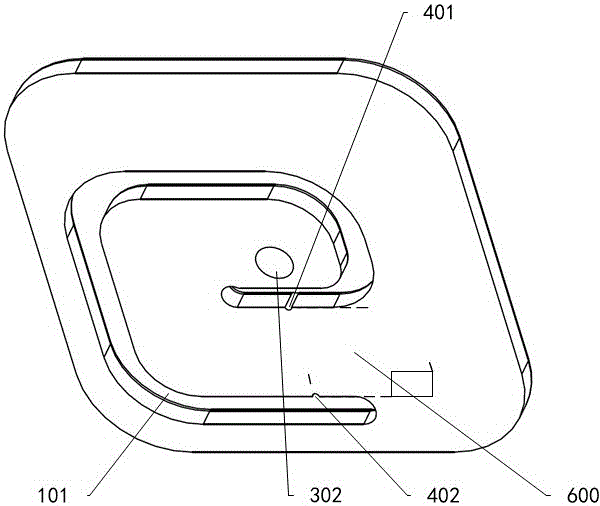

Special-shaped metal cantilever weighing device

InactiveCN105806461AImprove output sensitivityEasy to fixWeighing apparatus using elastically-deformable membersWeighing apparatus detailsMetal sheetCantilever

The invention provides a special-shaped metal cantilever weighing device.A flaky weight sensor is formed by a rectangular metal sheet (100) with a G-shaped hollowed-out part (101).The metal sheet (100) and the hollowed-out part (101) jointly form a C-shaped cantilever.The part between the hollowed-out part (101) and the metal sheet forms a cantilever front part (201), the part perpendicular to the cantilever front part (201) is a cantilever middle part (202), and the remaining part of the cantilever is a cantilever rear part (203).The cantilever front part (201) is a free end provided with a front protrusion (301) and a corresponding front pit (302).The special-shaped metal cantilever weighing device is characterized in that the width of the cantilever front part (201) is 10% larger than that of the cantilever rear part (203) so that overlarge torque cannot be generated on the cantilever rear part (203) while the front protrusion (301) and the corresponding front pit (302) are formed on the cantilever front part (201).

Owner:PICOOC TECH CO LTD

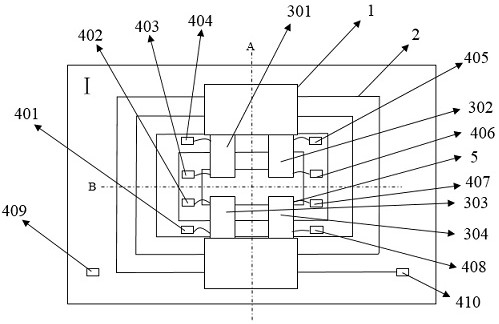

Pure axial deformation based MEMS three-axis piezoresistive accelerometer chip and preparation method thereof

ActiveCN110531114AExcellent performance indexEnables separate measurementsTelevision system detailsAcceleration measurement using interia forcesClassical mechanicsDirect coupling

The invention discloses a pure axial deformation based MEMS three-axis piezoresistive accelerometer chip and a preparation method thereof. An X measurement unit, a Y measurement unit and a Z measurement unit in a sensor are used for measuring the accelerations in the X direction, the Y direction and the Z direction respectively, so that the separate measurement of the accelerations in the three directions is realized; each measurement unit comprises mass blocks, a supporting beam and a sensitive beam; for no matter which of the measurement units, the supporting beam and the sensitive beam areseparately arranged through the mass blocks, the supporting beam supports the mass blocks to move, and the stress is mainly concentrated in the sensitive beam, so that the resistance value of a piezoresistor strip on the sensitive beam is changed; the supporting beam and the sensitive beam perform respective functions, so that the direct coupling relation between the sensitivity and the resonant frequency is greatly weakened; meanwhile, due to the synchronous movement of the two mass blocks, the two ends of the sensitive beam fixed with the mass blocks synchronously move, and the sensitive beam always meets the pure axial deformation condition; and under the same resonant frequency, the sensitivity of the sensor is optimal, so that the sensor chip has good performance indexes.

Owner:XI AN JIAOTONG UNIV

Piezoelectric acceleration sensor

ActiveUS9016127B2Improve output sensitivitySmall sizeAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsEngineeringAcceleration Unit

Owner:TOKIN CORP

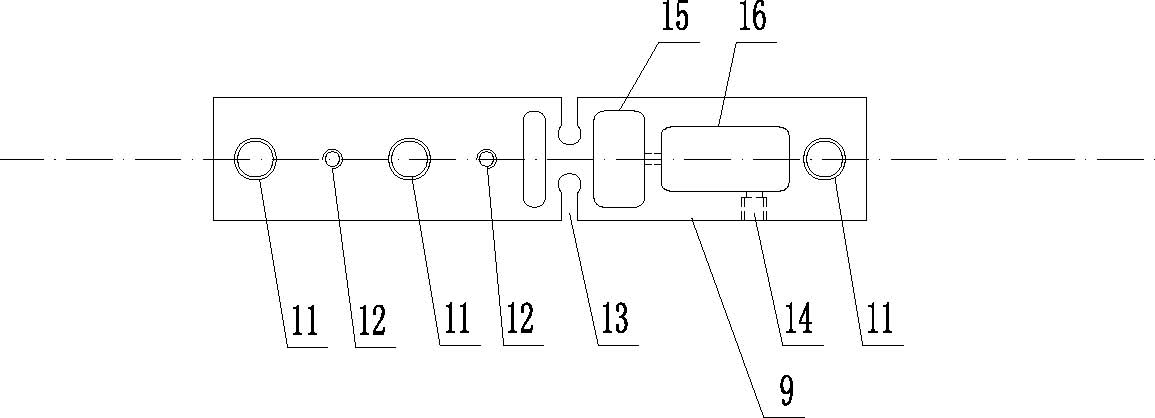

Wide-range inductance measuring head

InactiveCN103090782AStable and accurate distance measurementHigh precisionUsing electrical meansEngineeringSteel ball

A wide-range inductance measuring head is composed of a measuring guide rail and a measuring magnetic circuit in a connecting mode. The measuring guide rail is formed by the fact that a measuring rod is arranged inside a shaft sleeve. A measuring head is arranged at the front end of the measuring rod, a measuring steel ball is embedded at the front end of the measuring head, a holder is arranged on the measuring rod, four rows of stabilized steel balls are evenly arranged between the holder and the measuring rod, the rear portion of the measuring rod is connected with the front end of the holder, and a limiting device is further arranged on the measuring rod. The measuring magnetic circuit is that a magnetic core is arranged inside a magnetic sleeve, a coil framework is sleeved outside the magnetic core, a left magnetic ear and a right magnetic ear are respectively arranged at two ends of the magnetic core, and a left limiting device and a right limiting device are further arranged on the left magnetic ear and the right magnetic ear. A connecting rod is arranged at the right end of the magnetic sleeve, the connecting rod penetrates through the right magnetic ear and is connected with the magnetic core, and a spring device is arranged on the connecting rod.

Owner:三门峡锐鑫测控量仪有限公司

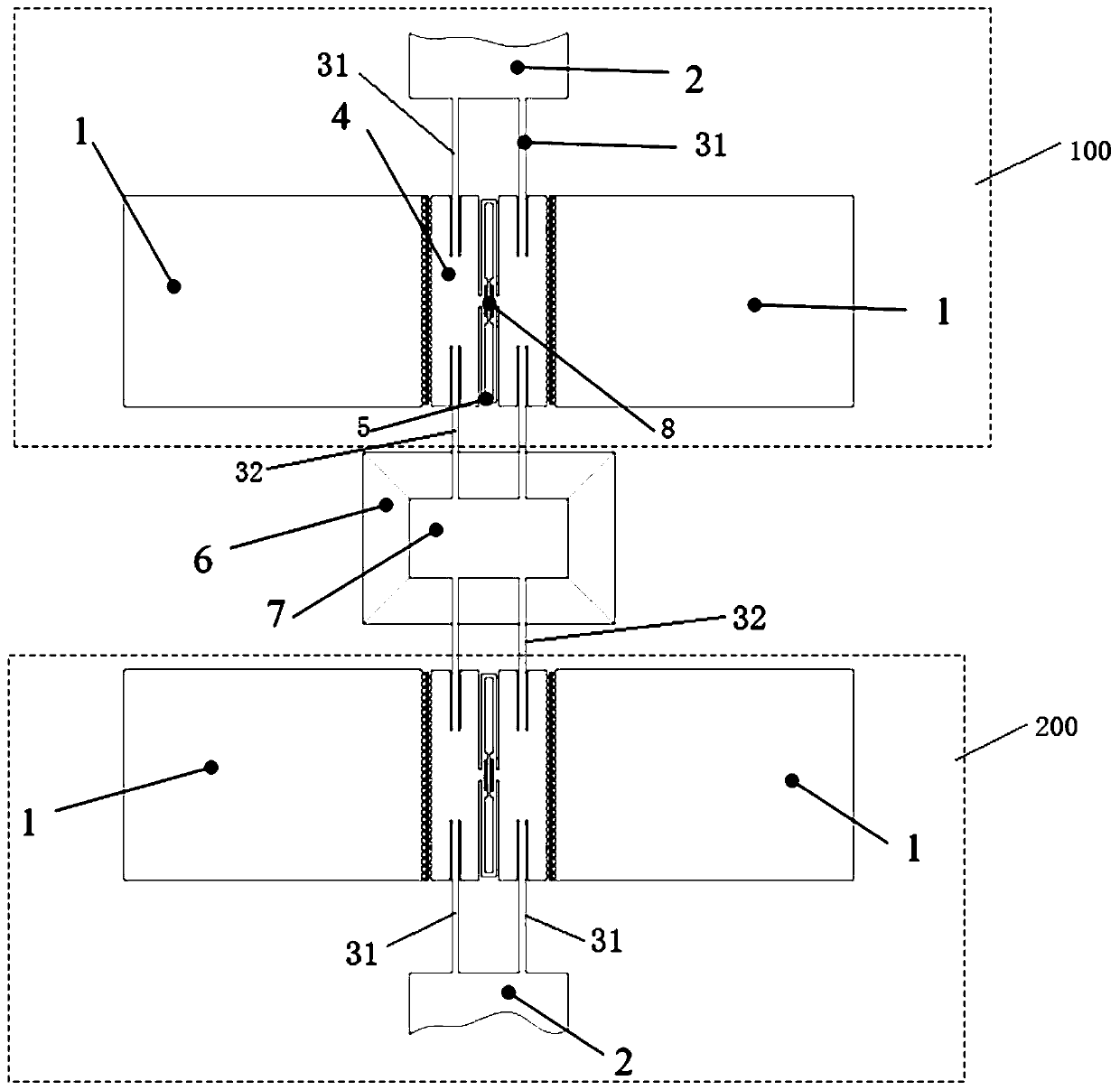

Double rood beam high-sensitivity six-dimensional moment sensor

The invention discloses a double rood beam high-sensitivity six-dimensional moment sensor in the technical field of robots. The double rood beam high-sensitivity six-dimensional moment sensor comprises two rood beams, two dead rings, one outer ring, and a plurality of resistance strain gages; a first rood beam and a second rood beam are arranged outside the outer ring respectively and are used as elastic bodies of the sensor for sensing stress; two dead rings are arranged outside the first rood beam and the second rood beam respectively; the resistance strain gages are adhered to the rood beams; each of the rood beams consists of four identical double-hole parallel sub beams; each double-hole parallel sub beam is provided with an I-shaped through hole; and a center hole is formed in the geometric center of each rood beam. In the double rood beam high-sensitivity six-dimensional moment sensor, floating beams used by the conventional six-dimensional moment sensor and crosstalk caused by the floating beams are removed, multi-component coupling is reduced conveniently and the measurement accuracy is improved.

Owner:SHANGHAI JIAOTONG UNIV

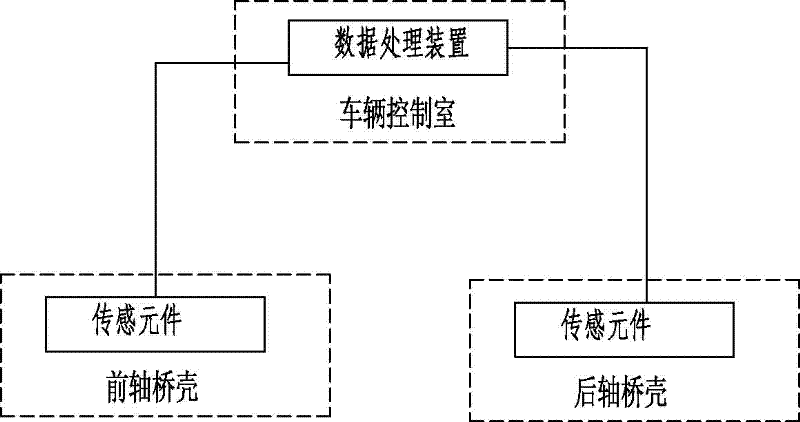

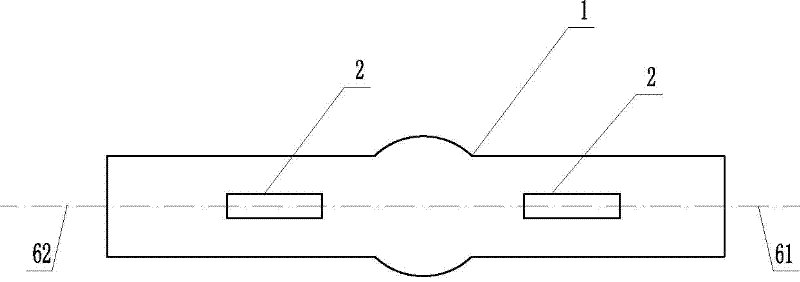

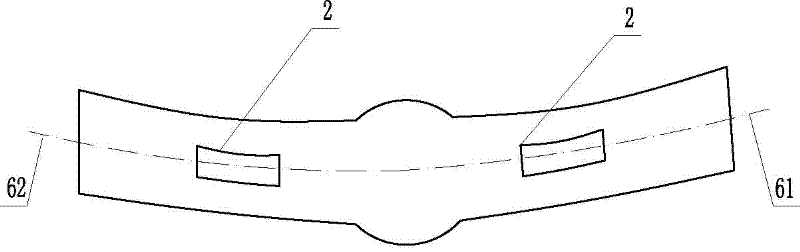

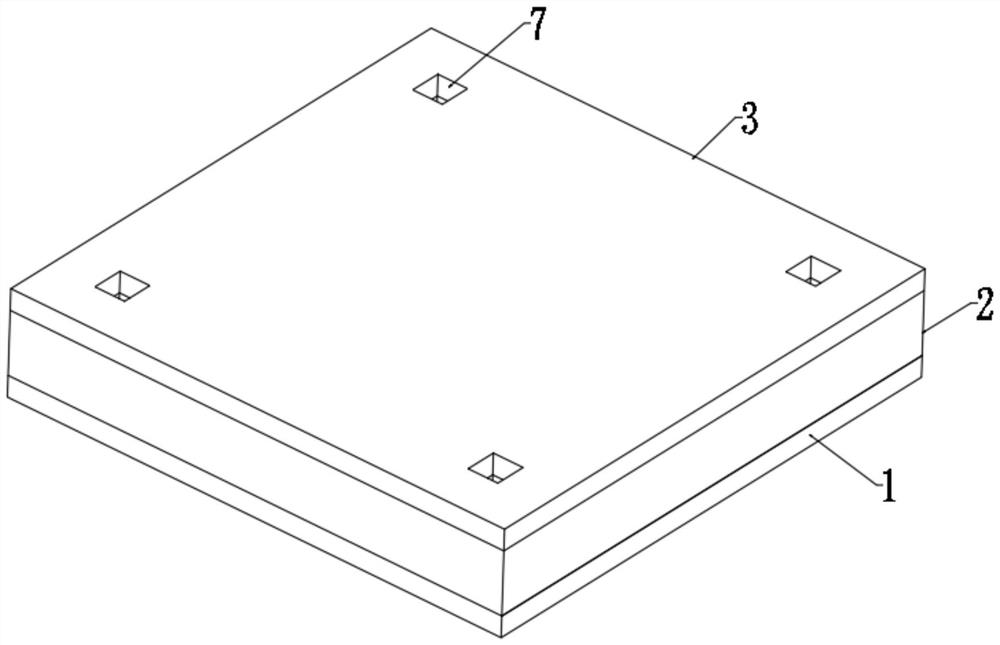

Weighing sensing system based on deformation quantity detection of vehicle axle housing

The invention discloses a sensing system by detecting deformation quantity of a vehicle axle housing to weigh the load. The weighing sensing system based on deformation quantity detection of the vehicle axle housing comprises a sensing element and a data processing device; and the weighing sensing system also comprises an elastic body for carrying the sensing element, wherein the sensing element is arranged inside the elastic body, and the elastic body is arranged on a neutral plane position on the surface wall of the vehicle axle housing. Due to the adoption of the weighing sensing system based on the deformation quantity detection of the vehicle axle housing, technical weaknesses of the prior art that detection data cannot reflect the real load situation and the service life of the sensing element is influenced because the stress deformation can cause unnecessary internal stress influence on the sensing element can be overcome, relative precision of the detection can be realized, and the sensing element can be effectively protected.

Owner:重庆大唐科技股份有限公司

High-g-value and high-sensitivity MEMS acceleration sensor and preparation method thereof

PendingCN113504392AEncapsulation is easy to implementImprove output sensitivityAcceleration measurement using interia forcesFinal product manufactureEngineeringMechanical engineering

The invention discloses a high-g-value and high-sensitivity MEMS acceleration sensor, and belongs to an MEMS acceleration sensor. Thehigh-g-value and high-sensitivity MEMS acceleration sensor comprises a substrate, a device layer and a cover plate, the substrate and the cover plate are respectively bonded with the device layer from two sides of the device layer, the device layer comprises an outer frame, a mass block and four support beams, the mass block and the four supporting beams are located in the outer frame. By adopting the design scheme that four T-shaped structure supporting beams are connected with the mass block, the x, y and z axial stop structures are innovatively designed, and the sensor adopts a cover plate-device layer-substrate sandwich packaging structure, so that batch wafer-level packaging is easy to realize; the supporting beams adopts a double-E-shaped structural design, so that the output sensitivity of the device is greatly improved; pressing film damping between the device layer and the cover plate and between the device layer and the substrate is optimized, the overall dynamic performance of the sensor is improved, and the service life of the device is prolonged.

Owner:美满芯盛(杭州)微电子有限公司

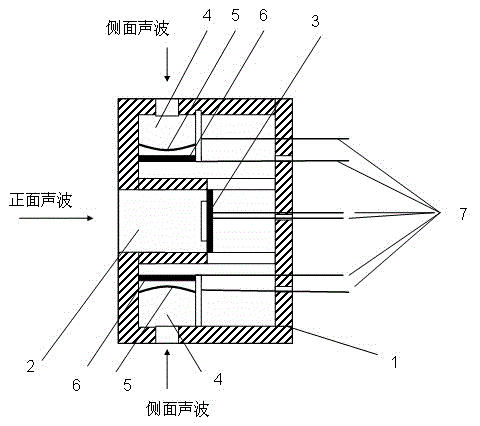

Gas outburst sensor based on sound wave principle

InactiveCN102879463AReal-time monitoringTo achieve the purpose of highlighting monitoring and early warningAnalysing fluids using sonic/ultrasonic/infrasonic wavesSonificationHigh pressure

The invention discloses a gas outburst sensor based on a sound wave principle and belongs to a gas sensor. The gas outburst sensor comprises a casing, a frontal sound cavity, an ultrasound piezoelectric film, lateral sound cavities, metal films, fixing electrode plates and a lead, wherein the frontal sound cavity is arranged in front of the casing, the lateral sound cavities are arranged on the side of the casing, the ultrasound piezoelectric film is connected in the frontal sound cavity, the metal films and the fixing electrode plates are sequentially connected in the lateral sound cavities, the lead and the ultrasound piezoelectric film are connected at the back of the casing, at the same time, the lead, the metal films and the fixing electrode plates are arranged, the frontal sound cavity and the ultrasound piezoelectric film form an ultrasonic detector, the number of the lateral sound cavities, the metal films and the fixing electrode plates is respectively two, the lateral sound cavities, the metal films and the fixing electrode plates form two low-frequency acoustic detectors, and by the aid of detection of high-frequency sound waves and low-frequency sound waves, sound waves produced by gas jet which is ejected out of seams of coal layers can be analyzed. The gas outburst sensor has the advantages that high-frequency sound wave signals and low-frequency sound wave signals which are ejected out by the high-pressure gas in the coal layers through seams of the coal layers can be detected, and real-time monitoring for mine gas outburst is achieved.

Owner:徐州中国矿业大学科技发展总公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com