Multifunctional force cell sensor

A force sensor and multi-functional technology, applied in the field of force sensor, can solve the problems of great influence on measurement accuracy, great influence of temperature change, and small resistance strain gauge, so as to improve measurement accuracy and sensitivity, strong adaptability, and induction The effect of voltage enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

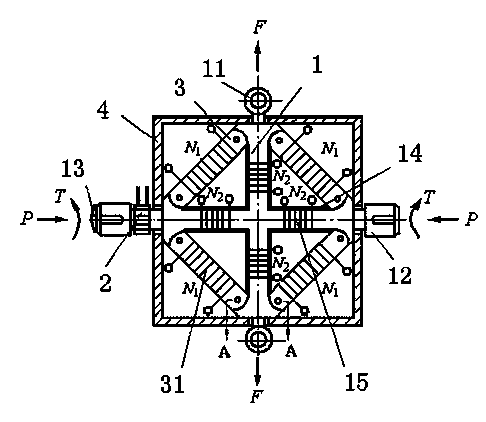

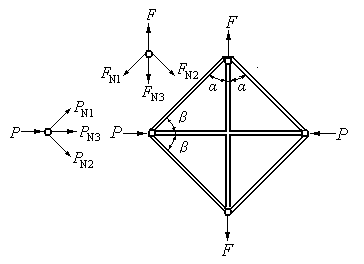

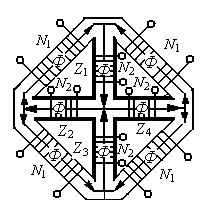

[0018] A multifunctional load cell, see figure 1 , the sensor includes a cross elastic shaft 1, an output and input collector ring 2, a magnetically conductive connecting rod 3, and an anti-magnetic interference shield 4; both the cross elastic shaft and the magnetically conductive connecting rod are arranged in the anti-magnetic interference shield; the four cross elastic shafts The arms are of equal length and are made of 40Cr steel. A tension ring 11 for measuring tension is installed at both ends of the vertical direction, and a coupling 12 for measuring torque and a pressure head 13 for measuring pressure are respectively installed at both ends of the horizontal direction; The iron-based nano-crystalline alloy adhesion layer 14 is attached to the bearing surface, and a layer of iron-based nano-crystalline alloy with a thickness of 30-50 μm can be attached to the bearing surface of the cross elastic bearing by laser cladding, thermal spraying, pasting, etc. The number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com